To diagnose pump pressure problems, start by noting symptoms like fluctuating pressure or weak flow. Gather tools like a pressure gauge and a multimeter, then inspect the pump for leaks, corrosion, or unusual noises. Check the pressure readings and monitor system performance, looking for signs of wear or blockages. Conduct pressure tests to identify fluctuations or drops. By following these steps, you can pinpoint issues and solve most pressure concerns — more details are explained below.

Key Takeaways

- Check for abnormal noises, vibrations, or leaks around the pump and pressure tank.

- Use a calibrated pressure gauge to measure system pressure and identify fluctuations.

- Inspect pump components for wear, corrosion, leaks, or damage visually and physically.

- Test electrical wiring and motor function with a multimeter to rule out electrical issues.

- Verify pressure settings, pressure relief valve operation, and flow rates against manufacturer specifications.

Recognizing the Signs of Pump Pressure Issues

Pump pressure problems often become noticeable through specific signs that indicate your system isn’t functioning properly. You might notice your pump running longer than usual or struggling to reach the desired pressure. Weak water flow or inconsistent pressure can also signal an issue, making showers or faucets less effective. If you hear unusual noises like banging or whining, it’s a red flag. Additionally, frequent cycling—where the pump turns on and off repeatedly—can point to pressure problems. Keep an eye out for leaks around the pump or pressure tank, as these often correlate with pressure issues. Recognizing these signs early helps you address problems before they escalate, saving time and preventing more extensive damage to your system. Being aware of pump oil levels and ensuring proper lubrication can also play a role in maintaining optimal pump pressure. Regular maintenance and system monitoring can help prevent unexpected failures and extend the lifespan of your pump. Implementing pressure regulation devices can further stabilize system performance. Furthermore, understanding automation in business can inspire solutions that improve the efficiency of your pumping system. Additionally, consulting with a professional technician can provide tailored solutions for persistent pressure issues.

Gathering Essential Diagnostic Tools and Equipment

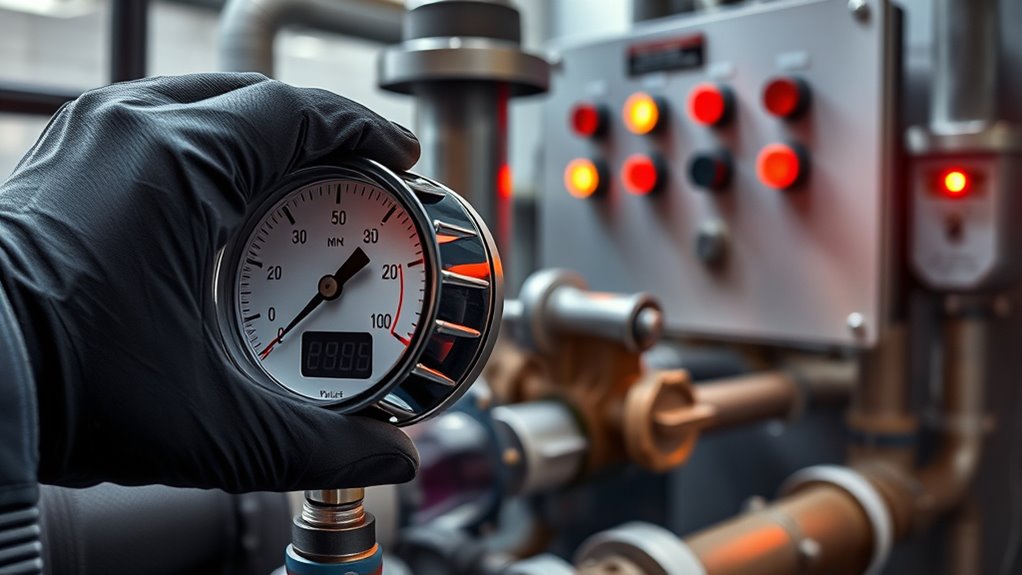

Before you can accurately diagnose pressure problems, it’s essential to gather the right tools and equipment. These will help you pinpoint issues efficiently and avoid guesswork. First, you’ll need a reliable pressure gauge to measure pump pressure accurately. A multimeter is useful for testing electrical components. Additionally, a flashlight helps you inspect hard-to-see areas. Here’s what you’ll need:

| Tool | Purpose | Notes |

|---|---|---|

| Pressure gauge | Measure pump pressure | Ensure calibration is recent |

| Multimeter | Test electrical circuits | Use for wiring inspection |

| Flashlight | Inspect components visually | Bright, focused beam |

Having these tools ready means you’re prepared to identify pressure irregularities swiftly and effectively, especially when considering the color accuracy of your equipment to ensure precise readings. Proper use of these tools can also help prevent misdiagnosis of underlying issues. Additionally, understanding the pressure fluctuations can guide you in making necessary adjustments or repairs, which is crucial for maintaining optimal pump performance. Moreover, being aware of air leaks in the system can significantly impact your diagnosis and repair process.

Inspecting the Pump and Its Components

To properly diagnose pressure issues, start by visually inspecting the pump and its components for signs of wear, damage, or leaks. Look for cracks, corrosion, or corrosion spots that may indicate deterioration. Check seals, gaskets, and fittings for leaks or looseness. Examine the pump shaft and impeller for corrosion, cracks, or warping. Ensure bolts and fasteners are tight and secure. Observe the condition of hoses and connections — any bulges, cracks, or leaks could impair performance. Don’t forget to check for unusual debris or buildup that could clog or restrict flow. A thorough visual inspection helps you identify obvious problems early, saving time and preventing further damage. Addressing these issues promptly can restore proper pressure and keep your system running smoothly. Additionally, monitoring sensor data can provide real-time insights into pump performance and help detect emerging problems before they escalate. Recognizing Volkswagen Tuning influences on engine behavior can also aid in diagnosing pressure irregularities linked to modifications. Being aware of performance modifications in your system can help you better understand potential causes of pressure fluctuations. Regularly inspecting the pump’s bearings can also prevent unexpected failures and prolong the lifespan of the equipment. Furthermore, understanding the impact of wear and tear on components can guide more effective maintenance strategies.

Monitoring Pressure Gauges and Flow Rates

Monitoring pressure gauges and flow rates provides real-time insights into your system’s performance, allowing you to detect issues as they happen. Regularly check gauges to guarantee pressures stay within recommended ranges; deviations can indicate blockages, leaks, or pump wear. Keep an eye on flow rates to confirm the pump delivers the expected volume; drops may signal obstructions or damaged components. Record readings consistently to identify trends over time. Sudden changes in pressure or flow often point to developing problems that require prompt attention. Use a reliable gauge and ensure it’s properly calibrated for accurate measurements. Incorporating pressure monitoring techniques can also assist in tracking and analyzing data more effectively. Additionally, understanding how city dynamics influence system performance can help anticipate potential challenges and optimize maintenance schedules.

Conducting Visual and Physical Inspections

Performing regular visual and physical inspections is essential for identifying early signs of pump issues. Start by checking for leaks around seals, fittings, and connections, as even small drips can indicate problems. Look for corrosion, rust, or buildup on the pump housing and components, which can signal deterioration. Feel for unusual vibrations or excessive heat when touching the pump, as these may point to bearing failures or misalignment. Inspect the drive belt or coupling for wear or looseness, ensuring they’re properly tensioned. Listen for abnormal noises like grinding or squealing, which suggest internal damage. Additionally, examine the motor and electrical connections for signs of wear, corrosion, or loose wiring. Catching these issues early helps prevent more significant failures and keeps your pump running smoothly.

Testing Pressure With a Manometer or Pressure Tester

Testing pressure with a manometer or pressure tester is a straightforward way to assess your pump’s performance. First, verify your pump is operating under normal conditions. Attach the pressure tester or manometer securely to the system’s test port or pressure outlet. Turn on the pump and observe the readings, noting the pressure level compared to the manufacturer’s specifications. If the pressure is too low, it could indicate a leak, block, or worn components. Excessively high pressure might suggest a faulty pressure relief valve or blockage downstream. Always record your readings and perform multiple tests to confirm consistency. Properly calibrate your testing device before use to ensure accuracy. This step helps you identify if the pump is operating within the correct pressure range, guiding your next troubleshooting steps.

Analyzing System Performance and Identifying Anomalies

Once you’ve recorded pressure readings with a manometer or pressure tester, the next step is to analyze system performance for any signs of irregularities. Look for pressure fluctuations or drops that don’t align with normal operation. Consistent low pressure might indicate a leak, a worn-out seal, or an inadequate pump. Conversely, unusually high pressure could suggest a blockage or a faulty pressure relief valve. Pay attention to how pressure changes during different system activities; abrupt shifts may reveal flow restrictions or component failures. Comparing your readings to manufacturer specifications helps identify deviations. Keep detailed notes of your observations, as patterns and anomalies will guide your next troubleshooting steps and help you pinpoint the root cause of the pressure issues.

Implementing Troubleshooting Steps to Resolve Pressure Problems

To effectively resolve pressure problems, you should follow a systematic troubleshooting process that targets the most common causes first. Begin by inspecting the pump’s inlet filter for clogs or debris that could restrict flow. Next, check for leaks in hoses, fittings, or seals, as these can cause pressure drops. Verify that the system’s pressure settings match manufacturer specifications, adjusting if necessary. If the pump isn’t reaching expected pressure, test the pressure relief valve for proper operation. Also, examine the pump’s impeller for damage or wear, which can reduce efficiency. Finally, ensure the pump is correctly primed and that its motor is functioning smoothly. Following these steps methodically helps pinpoint issues quickly, minimizes downtime, and restores ideal pressure performance efficiently.

Frequently Asked Questions

What Are Common Causes of Pump Pressure Fluctuations?

You might notice pump pressure fluctuations caused by several common issues. Check for inconsistent power supply or electrical problems, which can disrupt pump operation. Mechanical wear or damage to components like valves or seals also causes pressure changes. Blockages or restrictions in hoses or filters can reduce flow, leading to pressure variations. Additionally, irregular system demand or temperature fluctuations can impact pressure, so regularly inspecting and maintaining your pump system helps prevent these issues.

How Often Should Pump Pressure Be Tested Routinely?

You should test your pump pressure regularly to guarantee ideal performance. Typically, it’s recommended to check pressure once a month, but this can vary depending on your system’s specifications and usage. Regular testing helps you catch issues early and maintain consistent operation. Always follow your manufacturer’s guidelines for the most accurate testing intervals, and consider more frequent checks if you notice any fluctuations or performance problems.

Can Temperature Affect Pump Pressure Readings?

Temperature can definitely influence your pump pressure readings. When temperatures rise, the fluid inside the system expands, which can cause higher pressure readings. Conversely, colder temperatures make the fluid contract, potentially leading to lower readings. You should always consider the ambient temperature and fluid temperature when taking measurements. To guarantee accuracy, perform pressure tests in consistent temperature conditions or allow the system to reach equilibrium before testing.

What Safety Precautions Are Necessary During Diagnostics?

Did you know that nearly 30% of workplace accidents occur during maintenance? When diagnosing pump pressure issues, safety is essential. Always wear appropriate PPE, including gloves and eye protection. Make certain the system is depressurized before opening any components to prevent sudden releases of pressure. Follow manufacturer guidelines carefully, and never bypass safety controls. Staying vigilant and cautious helps prevent injuries and guarantees accurate diagnostics.

How Do I Interpret Inconsistent Pressure Gauge Readings?

When you see inconsistent pressure gauge readings, it indicates possible issues with your pump or system. You should first check for loose connections or damaged gauges, as these can cause false readings. Keep an eye on fluctuations while the system runs, and compare readings at different times. If inconsistencies persist, consider inspecting the pump for wear or blockages, and calibrate the gauge to guarantee accurate measurements.

Conclusion

By staying vigilant and methodical, you can uncover the hidden clues behind pump pressure issues. Think of your system as a delicate machine—when one part falters, the whole process suffers. With the right tools and a keen eye, you’re the detective solving the mystery. Remember, troubleshooting isn’t just fixing a problem; it’s restoring harmony to your system’s rhythm, ensuring it runs smoothly like a well-tuned orchestra.