To keep your chainsaw running safely and efficiently, follow a maintenance schedule that includes daily inspections of the chain tension, safety features, and cleaning, along with weekly tasks like cleaning the bar and chain and checking the spark plug. Perform monthly tune-ups, seasonally deep clean parts, and annually replace worn components. Staying consistent with this routine guarantees peak performance and safety—stick around to learn more about each step in detail.

Key Takeaways

- Perform daily safety feature checks, including chain brake, throttle lock, and safety switches, before each use.

- Conduct weekly maintenance by cleaning the chain, bar, and air filter, and checking chain tension and sharpness.

- Schedule monthly inspections to adjust chain tension, sharpen or replace dull teeth, and verify engine components.

- Carry out seasonal deep cleaning of the bar, chain, and vents; inspect for wear, rust, or damage on key parts.

- Complete annual servicing by replacing worn parts, testing safety features, and maintaining detailed maintenance records.

Daily Inspection and Basic Cleaning

To keep your chainsaw running smoothly, you should perform a daily inspection and basic cleaning before each use. Start by checking the chain tension; it should be tight enough to prevent slack but still move freely. Examine the chain for any damage or dullness, and sharpen it if necessary. Next, look for debris, sawdust, or oil build-up around the bar and chain; clean these areas with a brush or cloth. Inspect the air filter for dirt or clogging, and clean or replace it if needed. Check the spark plug for signs of wear or corrosion. Also, ensure the chain brake and throttle operate properly. Performing these simple steps daily helps prevent problems, extends your chainsaw’s lifespan, and ensures safe, efficient cutting every time. Additionally, regularly inspecting the fire safety equipment around your work area helps prevent accidents and ensures a quick response in case of emergencies. Regularly checking the hydrocolloid material in acne patches can also improve their effectiveness by maintaining proper moisture levels. Incorporating routine preventive maintenance based on manufacturer recommendations can further enhance the chainsaw’s performance and safety. Regular maintenance routines can also include checking the condition of your chainsaw’s oil supply, which is vital for proper lubrication. Remember that consistent maintenance routines contribute to the overall organization of your tools and workspace, making your tasks more efficient and safe.

Weekly Maintenance Tasks

After completing your daily inspections, it’s time to focus on weekly maintenance tasks that help keep your chainsaw in top condition. First, remove the chain and bar to clean them thoroughly. Use a brush to clear out any built-up debris and check for signs of wear or damage. Lubricate the chain and bar with fresh bar oil to ensure smooth operation. Inspect the chain’s tension and adjust if necessary, making sure it’s neither too tight nor too loose. Additionally, check the spark plug for dirt or corrosion and clean or replace it if needed. Finally, examine the air filter, removing and cleaning it to prevent dust buildup that can hamper performance. Regularly inspecting and maintaining the chain reservoir system can further enhance your chainsaw’s longevity and safety. Incorporating consistent messaging about maintenance routines can motivate proper care and extend equipment lifespan. Performing predictive maintenance by monitoring parts for signs of wear can help prevent unexpected breakdowns. Incorporating proper safety precautions during maintenance is essential to prevent accidents and injuries. Completing these tasks weekly keeps your chainsaw running efficiently and extends its lifespan.

Monthly Checks and Tune-Ups

Have you scheduled your monthly chainsaw checks yet? This is the time to give your saw a thorough inspection to keep it running smoothly. Start by checking the chain tension—if it’s too loose or tight, adjust it according to the manufacturer’s instructions. Inspect the chain for dullness, damage, or missing teeth, and sharpen or replace it as needed. Clean the air filter to prevent engine strain and guarantee maximum performance. Regular cleaning also helps maintain spiritual well-being, ensuring your tools are in optimal condition. Examine the spark plug for wear or deposits, replacing it if necessary. Also, look over the fuel system for leaks or clogs. Tighten all nuts and bolts, and lubricate moving parts to prevent rust and corrosion. Regular monthly maintenance keeps your chainsaw reliable and extends its lifespan. Additionally, consider inspecting the air filtration system to ensure optimal engine operation and prevent dust and debris buildup. Regularly checking the engine oil level helps maintain proper lubrication and prevents overheating. Proper filter maintenance is essential for efficient operation and minimizing engine wear. Incorporating routine oil checks can further help identify potential issues early and ensure smooth operation.

Seasonal Deep Cleaning and Inspection

As the seasons change, it’s essential to perform a thorough deep cleaning and inspection of your chainsaw to guarantee peak performance and safety. Start by removing debris, dust, and sap from the bar, chain, and vents. Check for signs of wear, rust, or damage. Make certain the chain is sharp and properly tensioned. Inspect the guide bar for uneven wear or cracks. Regular cleaning prevents buildup that can hinder operation or cause overheating. Using tuning techniques can help optimize your chainsaw’s performance over time. Use the table below to remember key inspection points:

| Inspection Area | What to Look For | Action Needed |

|---|---|---|

| Chain | Sharpness, tension | Sharpen or tighten |

| Guide Bar | Wear, cracks | Replace if damaged |

| Air Filter | Dirt, clogging | Clean or replace |

| Sprocket & Clutch | Wear, damage | Replace if necessary |

Additionally, ensuring your suction power is adequate can help maintain the chainsaw’s performance by preventing dust and debris buildup, which could impair the engine or moving parts. Proper air flow is crucial for efficient operation and avoiding overheating.

Annual Servicing and Part Replacements

Regular maintenance doesn’t end with seasonal cleaning; performing thorough annual servicing guarantees your chainsaw stays in top condition. During this service, you should inspect and replace worn parts like the spark plug, air filter, and chain sprocket. Check the chain’s tension and sharpen the cutting teeth if needed. Replace the fuel filter and examine the oil delivery system for blockages. It’s also a good idea to inspect the muffler for carbon build-up and clean or replace it if necessary. Lubricate all moving parts thoroughly to prevent wear. Performing these replacements and inspections annually helps prevent breakdowns, improves cutting efficiency, and extends your chainsaw’s lifespan. Taking the time for this maintenance ensures your equipment remains safe and reliable for the long haul.

Safety Checks and Function Testing

Start by inspecting your chainsaw’s safety features, like the chain brake and throttle lock, to guarantee they’re working properly. Then, test the chain brake to confirm it stops the chain instantly when engaged. These checks are essential for safe operation and should be part of your regular maintenance routine.

Inspect Safety Features

Have you ever wondered if your chainsaw’s safety features are working properly? It’s essential to check each one before you start cutting. First, inspect the chain brake to ensure it engages smoothly and fully stops the chain when activated. Next, verify the throttle lockout functions correctly, preventing accidental acceleration. Examine the chain catch to confirm it’s secure and in good condition. Look over the handguards to ensure they’re intact and properly positioned to protect your hands. Check that the anti-vibration mounts are secure, reducing fatigue and maintaining control. Finally, test the operation of the trigger and any safety switches for responsiveness. These inspections help guarantee your chainsaw’s safety features are functioning, minimizing risks during operation and keeping you safe while working.

Test Chain Brake Function

Ever wondered if your chainsaw’s chain brake is working properly? You should test it regularly to confirm safety. To do this, wear gloves and hold the chainsaw firmly. Engage the chain brake and then try to turn the chain by hand or move it with your fingers. If the brake is functioning correctly, the chain shouldn’t move. If it still spins freely, the brake may need adjustment or replacement. Also, check the brake’s lever and handle for smooth operation, making sure it engages and releases easily. Performing this quick test helps prevent accidents caused by a malfunctioning brake. Regularly testing your chain brake keeps you safe while working and prolongs the life of your chainsaw’s safety features.

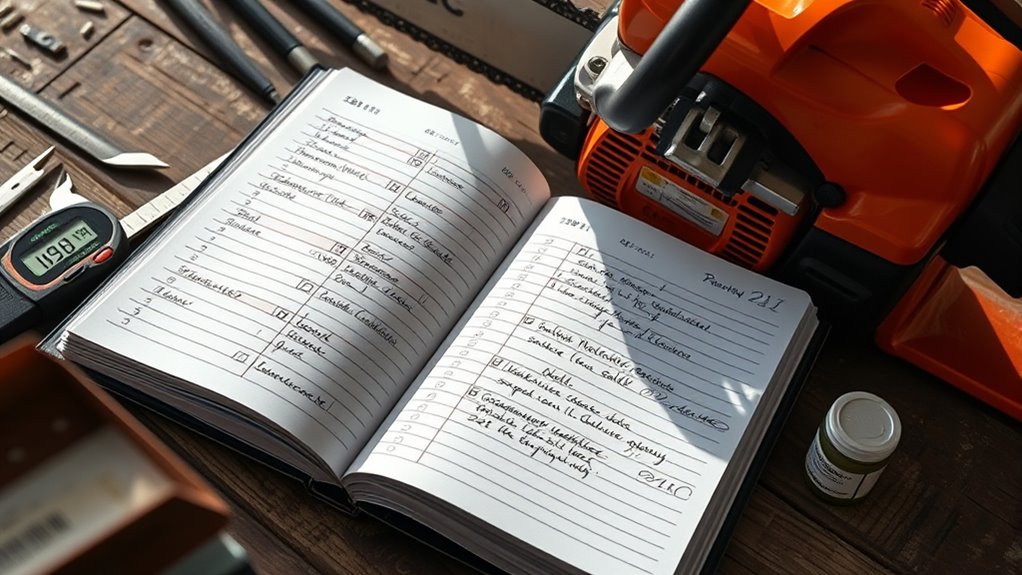

Record Keeping and Maintenance Log

Keeping a detailed maintenance log is essential for ensuring your chainsaw stays in ideal condition. By recording every service, inspection, and repair, you create a clear history of your chainsaw’s health. Each time you sharpen the chain, replace the spark plug, or check the air filter, note the date and what was done. This helps you identify patterns, anticipate upcoming needs, and avoid neglecting critical maintenance tasks. A well-maintained log also proves valuable if you need warranty service or sell your chainsaw, showing that it’s been properly cared for. Use a notebook or digital app to track these details consistently. Staying organized with your maintenance records keeps your chainsaw running smoothly and prolongs its lifespan.

Frequently Asked Questions

How Often Should I Replace the Chain Brake?

You’re wondering how often to replace the chain brake. Typically, you should inspect it regularly for damage or wear, especially after heavy use or a kickback incident. If you notice cracks, excessive wear, or if it no longer engages properly, it’s time to substitute it. There’s no fixed timeline—trust your inspection and replace it when it’s compromised to ensure your safety and proper chainsaw operation.

What’S the Best Way to Store a Chainsaw Long-Term?

You might think storing your chainsaw long-term is complicated, but it’s simple with the right steps. First, drain the fuel to prevent gum buildup and corrosion. Clean the chain and bar, then apply a light oil to prevent rust. Store it in a dry, cool place away from direct sunlight. Cover it with a tarp or case, and periodically check to make sure it remains in good condition.

How Do I Troubleshoot Starting Issues?

When your chainsaw won’t start, first check the spark plug for dirt or damage, and verify it’s properly connected. Next, verify there’s fresh fuel and that the fuel lines aren’t clogged. Clean or replace the air filter if it’s dirty. If the chainsaw still won’t start, inspect the carburetor for clogs and make sure the ignition switch is on. Regular maintenance helps prevent these issues.

Are There Different Maintenance Needs for Electric vs. Gas Chainsaws?

Think of your chainsaw as a finely tuned instrument; electric and gas models are like different musical instruments needing unique care. Gas chainsaws require regular checks on the spark plug, carburetor, and fuel system, while electric ones need battery maintenance and cord safety. You’ll want to clean air filters and inspect cords more often on electric models. Tailor your maintenance routine to keep both types singing smoothly and safely.

What Signs Indicate My Chain Needs Sharpening Urgently?

When your chain needs sharpening, you’ll notice the saw struggles to cut smoothly, requiring more effort. If it produces fine sawdust instead of thick chips, that’s a sign. You might also see uneven cuts or hear excessive vibration. If the chain looks dull with rounded teeth or if it slides off the wood easily, sharpen it immediately. Addressing these signs promptly keeps your chainsaw efficient and safe to use.

Conclusion

By sticking to this maintenance schedule, you guarantee your chainsaw stays in top shape and ready whenever you need it. Imagine a homeowner, Sarah, who skipped seasonal inspections and faced a sudden breakdown during a storm. Regular upkeep could have prevented that costly repair and kept her safe. Keep up with daily checks and scheduled maintenance to avoid surprises, so your chainsaw reliably handles every job, big or small.