If your chainsaw won’t start, start by checking the fuel system—use fresh, properly mixed gasoline and inspect fuel lines for clogging or leaks. Next, examine the spark plug for dirt or damage and ensure the gap is correct. Also, verify carburetor settings and clean or replace the air filter. Don’t forget to test compression and ignition components if needed. For detailed steps on each issue, keep exploring this guide.

Key Takeaways

- Check and replace old or stale fuel, and ensure proper fuel-to-oil mixture for reliable combustion.

- Inspect and clean or replace the spark plug, verifying correct gap and proper ignition function.

- Adjust carburetor mixture screws and idle speed to optimize engine start and smooth operation.

- Clean or replace the air filter to improve airflow and engine performance.

- Perform routine maintenance, including chain sharpening, securing fasteners, and proper storage to extend lifespan.

Checking the Fuel System

Have you checked the fuel system recently? If your chainsaw isn’t starting easily, low or stale fuel could be be the culprit. Start by inspecting the fuel tank; make sure it’s filled with fresh, properly mixed gasoline if your saw requires a mix of oil and gas. Old fuel can lead to poor engine performance or failure to start, so drain the tank if the fuel has been sitting for over a month. Next, check the fuel lines for cracks, blockages, or leaks—they should be clear and secure. Also, verify that the fuel filter isn’t clogged, as this restricts fuel flow. Taking these steps helps guarantee your chainsaw gets the proper fuel supply it needs to run smoothly. Additionally, understanding your fuel system can help prevent future starting issues. Being familiar with how the fuel mixture interacts with the engine can also improve troubleshooting efficiency. Regularly inspecting and maintaining the carburetor ensures optimal fuel delivery and engine performance. Checking the fuel pressure can also identify potential issues affecting start-up.

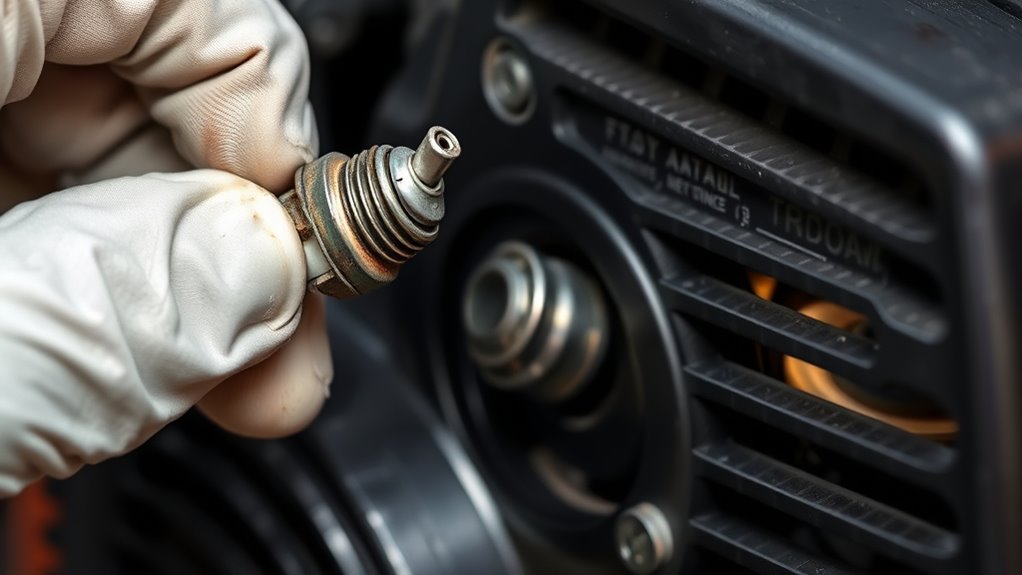

Inspecting the Spark Plug

If your chainsaw still isn’t starting after checking the fuel system, the spark plug might be the issue. Start by removing the spark plug with a spark plug socket or wrench. Inspect it for signs of damage, such as cracks or corrosion. Check the electrode gap with a feeler gauge; it should match the manufacturer’s specifications. If the spark plug looks dirty or fouled, clean it with a wire brush and reinstall it. If it’s damaged or worn out, replace it with a new one. Before testing, verify the spark plug’s boot is securely connected. A good spark plug is vital for proper ignition. Additionally, ensuring the spark ignition system is functioning correctly can help prevent starting issues. The efficiency of automation technologies can also influence the overall performance of the chainsaw’s ignition system. If replacing the plug doesn’t solve the problem, further troubleshooting may be necessary.

Examining the Carburetor Settings

Since the chainsaw still won’t start after checking the spark plug, it’s important to examine the carburetor settings. Improper adjustments can prevent fuel from entering the engine properly. First, locate the high-speed and low-speed mixture screws. Use a screwdriver to turn them clockwise or counterclockwise in small increments—typically 1/4 turn—to fine-tune the mixture. Be cautious not to over-tighten, which can cause damage. Here’s a quick reference:

| Adjustment Type | Purpose | Typical Direction |

|---|---|---|

| Low-speed screw | Controls idle and low RPMs | Turn clockwise to lean, counter for rich |

| High-speed screw | Regulates maximum power | Turn clockwise to lean, counter for rich |

| Idle speed screw | Sets engine idle speed | Turn clockwise to increase, counter to decrease |

Proper settings ensure smoother starts and better engine performance. Additionally, fuel mixture quality plays a crucial role in engine performance and starting reliability. Ensuring that the carburetor adjustments are correctly set can significantly improve starting consistency and overall engine health. Regularly checking and maintaining grocery store hours can also help plan timely visits for necessary parts or services.

Verifying the Spark Plug Gap

Verifying the spark plug gap is a crucial step in troubleshooting a chainsaw that won’t start. A gap that’s too wide or narrow can prevent the spark from igniting the fuel mixture properly. To check it, first remove the spark plug with a spark plug wrench. Then, look at the gap between the center and side electrode. Use a feeler gauge to measure the gap according to your chainsaw’s specifications, usually around 0.025 to 0.030 inches. If the gap is off, gently bend the side electrode to adjust it. Properly gapping the spark plug ensures a strong spark, which is essential for the engine to start and run smoothly. Always double-check the manufacturer’s recommended gap before reassembling. Additionally, maintaining the correct spark plug gap helps improve overall engine performance and longevity. Regularly inspecting the spark plug and keeping it clean can also prevent starting issues.

Assessing the Air Filter Condition

Start by inspecting the air filter for blockages or dirt buildup that could restrict airflow. Check to see if the filter is clean and free of debris, and replace it if it’s damaged or excessively dirty. Keeping the filter in good condition helps your chainsaw run smoothly and efficiently. Regularly cleaning and replacing the air filter ensures optimal performance and prevents engine issues. Additionally, maintaining a clean air filter supports AI-powered diagnostics, which can help identify other potential engine problems early on.

Inspect for Blockages

Have you checked the air filter recently? Blockages can restrict airflow, making your chainsaw hard to start. Remove the air filter and inspect it for debris, dust, or damage. If it’s clogged or dirty, airflow is limited, affecting engine performance. Clean or replace the filter if necessary. To help you assess, here’s a quick guide:

| Issue | Symptoms | Solution |

|---|---|---|

| Blocked Filter | Engine struggles to start | Clean or replace filter |

| Damage | Poor engine performance | Replace filter |

| Dirt Accumulation | Reduced airflow, stalls | Clean filter |

Regularly inspecting the filter helps prevent airflow issues that cause starting problems. Proper maintenance of your chainsaw ensures it runs smoothly and reduces the likelihood of hard starting issues. Additionally, ensuring the filter isn’t damaged or excessively dirty can prevent further engine problems, and understanding the importance of airflow can help you maintain optimal performance. Regularly checking the air filter condition is a simple yet effective way to keep your chainsaw running reliably.

Check Filter Cleanliness

Ever wondered how clean your air filter really is? A dirty air filter can choke your chainsaw’s airflow, making it hard to start. Remove the filter and examine it closely. If it’s covered in dirt, debris, or oil, it’s time to clean it. Wash the filter with warm, soapy water or use a designated cleaning solution, then let it dry completely before reinstalling. If the filter is excessively clogged or damaged, cleaning may not be enough. Keeping your air filter clean ensures proper fuel combustion and ideal engine performance. Regularly checking its condition prevents unnecessary strain on the engine and helps your chainsaw start smoothly every time. Don’t overlook this simple step—it can make all the difference in troubleshooting starting issues.

Replace if Damaged

If your air filter shows signs of damage after cleaning, it’s time to replace it. Damage can include tears, holes, or excessive wear that compromise its ability to filter air properly. A damaged filter allows dirt and debris to enter the carburetor and engine, risking further damage and poor performance. When inspecting the filter, look for:

- Torn or frayed edges

- Holes or rips in the filter media

- Excessive dirt buildup that won’t clean off

- Warped or misshapen frame

- Signs of mold, mildew, or foul odor

If you notice any of these issues, don’t hesitate to replace the filter. A new, undamaged filter ensures your chainsaw runs smoothly, efficiently, and reliably. Regular replacement prevents ongoing damage and keeps your engine in top shape.

Ensuring Proper Fuel Mixture

To keep your chainsaw running smoothly, make sure you’re using the correct fuel ratio every time. Always use fresh fuel to prevent engine issues and guarantee ideal performance. Proper mixing and fresh fuel are key to avoiding starting problems and engine damage.

Correct Fuel Ratio

Using the correct fuel mixture is vital for your chainsaw to run smoothly and avoid engine damage. If the ratio is off, you might experience hard starting, poor performance, or engine failure. Always measure your fuel accurately, following the manufacturer’s recommended ratio—usually 50:1 or 40:1. When mixing, consider the following:

- Use fresh, high-quality gasoline

- Mix thoroughly to ensure even fuel distribution

- Avoid using old or stale fuel

- Store fuel in a sealed, properly labeled container

- Double-check measurements before filling the tank

Getting the mixture right guarantees ideal combustion, reduces smoke, and prolongs engine life. Proper fuel handling is a simple but vital step to keep your chainsaw ready whenever you need it.

Fresh Fuel Use

Ensuring your chainsaw runs smoothly starts with selecting fresh fuel each time you fill the tank. Old fuel can cause starting issues because it deteriorates over time, leading to poor combustion. Always use fuel that’s been stored for no more than 30 days. Before refueling, check the fuel’s color and smell; if it looks or smells off, dispose of it and mix a fresh batch. Properly stored fuel in a sealed container helps prevent contamination and degradation. Avoid topping off the tank with old fuel; instead, drain any remaining fuel and add fresh mixture. Using fresh fuel ensures your chainsaw’s engine receives the right spark, leading to easier starts and reliable operation. Remember, fresh fuel is key to avoiding hard starts and keeping your chainsaw running efficiently.

Looking for Compression Issues

Are you experiencing difficulty starting your chainsaw or noticing it stalls unexpectedly? Low compression could be the culprit. To check, remove the spark plug and do a compression test with a gauge. If the reading is below manufacturer specifications, your engine isn’t producing enough power. Signs of compression issues include:

- Hard pulls on the starter cord

- Engine that sputters or dies quickly

- Lack of power during cuts

- Excessive smoking from the exhaust

- Visible damage or wear on piston and cylinder

A compression problem often points to worn piston rings, a damaged piston, or a blown head gasket. Addressing these issues may require replacing internal components or seeking professional repair. Proper compression ensures your chainsaw starts easily and runs smoothly.

Testing the Ignition System

Start by inspecting the spark plug for signs of wear or damage, ensuring it produces a strong spark. Next, test the ignition coil to verify it’s generating the proper voltage. Finally, check all wiring connections for looseness or corrosion that could disrupt the ignition system’s performance.

Spark Plug Inspection

How can you tell if your chainsaw’s spark plug is functioning properly? First, remove the spark plug and inspect its condition. Look for signs of wear, such as carbon buildup, fouling, or cracks. Check the electrode gap; it should match the manufacturer’s specifications. A dirty or damaged plug can prevent sparks from igniting the fuel mixture. To test it:

- Ensure the plug is clean and dry.

- Reattach it to the spark plug wire.

- Ground the metal tip against the engine block.

- Crank the engine and observe for a spark.

- Confirm the spark is strong and consistent.

If no spark appears or it’s weak, the plug may need cleaning, re-gap, or replacement. Proper spark plug function is essential for reliable starts and smooth operation.

Ignition Coil Testing

Wondering if your chainsaw’s ignition coil is working properly? To test it, first remove the spark plug and keep it grounded against the engine. Crank the engine and see if you get a spark; no spark indicates a problem. Next, use a multimeter set to ohms to check the coil’s resistance. Connect the meter’s leads to the primary and secondary terminals—refer to your chainsaw’s manual for specific resistance values. If readings are outside the recommended range, the coil may be faulty. Keep in mind that a weak or absent spark often points to a bad coil. If your tests reveal issues, replacing the ignition coil is often necessary to restore proper starting performance.

Wiring Connection Check

If your chainsaw isn’t starting or running smoothly, checking the wiring connections in the ignition system is an essential step. Faulty or loose wires can interrupt the spark, causing starting issues. First, locate the ignition module and inspect the wiring harness for damage or corrosion. Verify all connectors are firmly attached and free of debris. Look for frayed wires, broken insulation, or signs of wear. Use a multimeter to test continuity if needed. When inspecting, keep these in mind:

- Confirm tight, secure connections at the ignition module

- Check for corrosion or rust on terminals

- Look for cracked or frayed wiring insulation

- Ensure wires aren’t pinched or trapped

- Test for proper voltage with a multimeter

Address any issues before attempting to start the chainsaw again.

Cleaning the Fuel Lines and Filters

Cleaning the fuel lines and filters is essential for making certain your chainsaw runs smoothly. Over time, debris, dirt, and old fuel can clog these components, restricting fuel flow and causing starting issues. To clean them, first, turn off the chainsaw and disconnect the spark plug for safety. Locate the fuel lines and filters—usually near the carburetor. Carefully remove the fuel lines and inspect the filters; if they’re dirty or clogged, replace or clean them with a solvent or compressed air. Check the lines for cracks or damage, replacing them if necessary. After cleaning or replacing, reassemble everything securely. Doing this regularly helps maintain proper fuel flow, prevents engine stalls, and ensures your chainsaw starts easily whenever you need it.

Performing Routine Maintenance and Storage Tips

Performing routine maintenance and proper storage are essential for guaranteeing your chainsaw remains reliable and safe to use. Regular upkeep prevents issues that could cause starting problems or unsafe operation. You should:

Routine maintenance and proper storage ensure your chainsaw stays reliable, safe, and ready for use.

- Clean the saw thoroughly after each use to remove debris and sawdust.

- Check and tighten all nuts, bolts, and screws regularly.

- Sharpen the chain to ensure smooth cutting and reduce strain on the engine.

- Drain the fuel tank if storing the saw for an extended period to prevent gum buildup.

- Store the chainsaw in a dry, protected area, ideally hanging or on a shelf, away from children and pets.

These steps help extend your chainsaw’s lifespan, maintain its performance, and ensure safety during each use. Proper maintenance and storage are key to hassle-free operation.

Frequently Asked Questions

How Do I Identify if My Chainsaw’s Starter Mechanism Is Faulty?

When you suspect your chainsaw’s starter is faulty, start by inspecting the pull cord and recoil spring. If the cord feels loose, doesn’t retract properly, or there’s resistance when pulling, these are signs of a problem. Also, listen for unusual noises or difficulty in engaging the mechanism. Check for visible damage or corrosion around the starter assembly. If these issues persist, your starter likely needs repair or replacement.

What Are Signs of a Worn-Out Piston or Cylinder?

You’ll notice a worn-out piston or cylinder if your chainsaw struggles to start, loses power, or stalls quickly. Other signs include excessive smoke, unusual engine noise, or visible damage like scoring or scoring marks inside the cylinder. You might also see decreased compression, making it hard to pull the starter cord. Regular maintenance helps catch these issues early, preventing more serious engine damage down the line.

How Can I Tell if My Chainsaw Has a Timing Issue?

Think of your chainsaw’s timing like a well-choreographed dance. If it’s out of sync, your saw might sputter, stall, or have trouble revving up. You’ll notice it struggles to start, or the chain doesn’t move smoothly. To check, observe the spark plug’s timing mark and listen for irregular engine sounds. If things seem off, it’s likely a timing issue, and you should consider adjusting or replacing the timing components.

What External Factors Can Cause Hard Starting, Like Weather Conditions?

Weather conditions can make your chainsaw hard to start. Cold temperatures thicken the fuel and oil, making it harder for the engine to turn over. High humidity can also affect fuel mixture, reducing combustion efficiency. Additionally, damp or wet conditions can cause moisture buildup in the spark plug or air filter, leading to poor ignition. To prevent this, store your chainsaw in a dry place and consider using fuel stabilizers or additives designed for cold weather.

Are There Specific Safety Precautions Before Troubleshooting Engine Issues?

Before troubleshooting engine issues, you should take safety precautions to protect yourself. Always wear protective gear like gloves, goggles, and ear protection. Make sure the chainsaw is turned off and cool down before inspecting or working on it. Work in a well-ventilated area, and keep your hands and tools away from moving parts. Disconnect the spark plug to prevent accidental starts, and follow the manufacturer’s safety instructions carefully.

Conclusion

By systematically checking each component, you’ll demystify your chainsaw’s stubborn start. Think of it as tuning a finely crafted instrument—every part must play its role perfectly. With patience and a keen eye, you’ll turn frustration into confidence, ensuring your chainsaw roars to life whenever you need it. Remember, a well-maintained tool is like a reliable friend—ready to perform when called upon, making every cut smoother and more satisfying.