Chainsaw chain types vary based on tooth design and intended use. Full chisel chains cut quickly and smoothly, ideal for professionals but dull faster. Semi-chisel chains offer durability and are easier to sharpen, perfect for general tasks. Low profile chains are lightweight and user-friendly for homeowners, while round ground chains provide smooth cuts and reduce kickback. There are also specialized options like skip, double guard, and anti-vibration chains, all designed for specific jobs—if you continue, you’ll discover how to choose the right one for your needs.

Key Takeaways

- Chainsaw chains are classified into full chisel, semi-chisel, low profile, round ground, and specialty types based on tooth design and performance.

- Full chisel chains offer fast, precise cuts but dull quickly, ideal for professional use.

- Semi-chisel chains balance durability and efficiency, suitable for general-purpose tasks and easier sharpening.

- Low profile chains are lightweight, reduce vibration, and are perfect for light-duty work and homeowners.

- Specialty and anti-vibration chains enhance safety, durability, and performance for specific tasks and demanding applications.

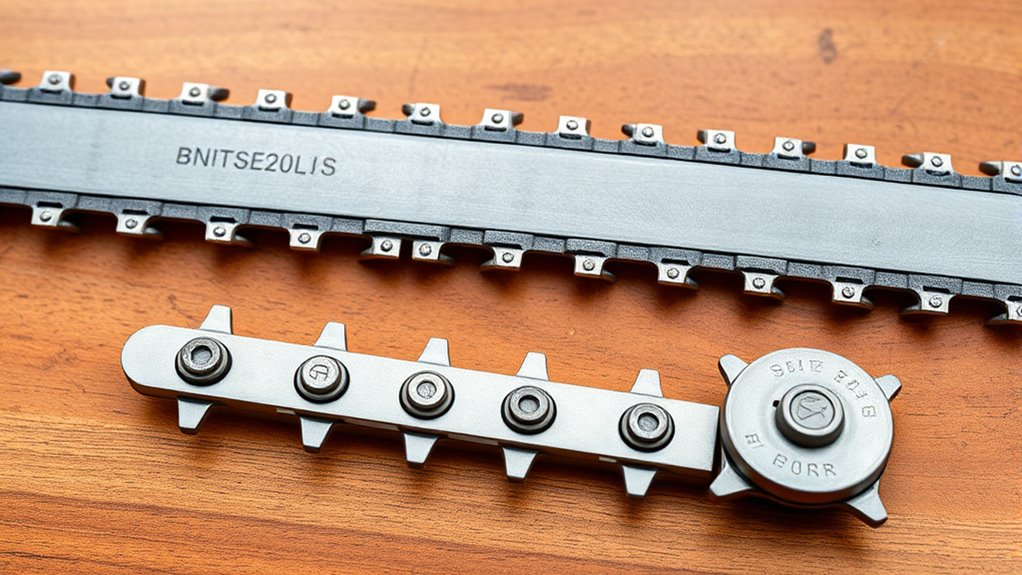

Full Chisel Chains

Have you ever wondered what makes full chisel chains so popular among professional arborists and woodcutters? The answer lies in their design; they feature squared, sharp cutting teeth that cut efficiently and quickly. These teeth have precise, square-cornered edges, allowing them to remove wood fibers cleanly and with minimal effort. Because of their sharpness, full chisel chains excel at cutting through softwoods and hardwoods alike, making them ideal for demanding tasks. However, they tend to dull faster than other chains, requiring more frequent sharpening. Despite this, their superior cutting speed and precision make them the top choice for professionals who need fast, clean cuts, especially when working on large projects or in professional settings.

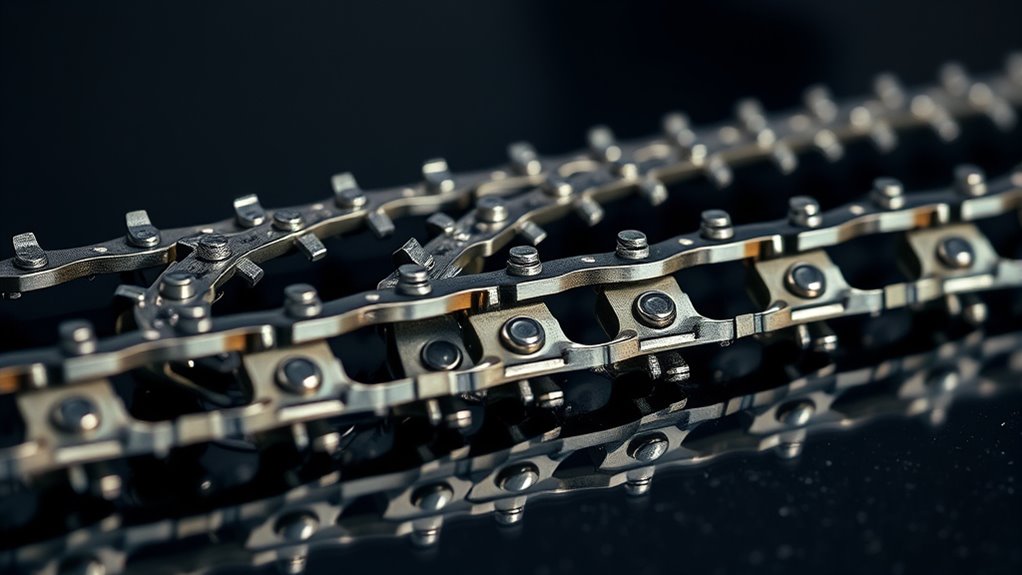

Semi-Chisel Chains

Semi-chisel chains strike a good balance between durability and cutting efficiency, making them versatile for various jobs. They tend to stay sharp longer and handle tougher wood better than some other types. Plus, they’re easier to maintain, so you spend less time on upkeep and more on your cutting tasks.

Durability and Cutting Efficiency

Although semi-chisel chains are designed with rounded cutting teeth, they strike a good balance between durability and cutting efficiency. Their rounded teeth hold up well against dirt and debris, making them less prone to dulling quickly. This means you can work longer without frequent sharpening, especially in tough or dirty wood. Durability, combined with their ability to maintain a steady cut, makes semi-chisel chains suitable for various tasks. While they may not cut as aggressively as full-chisel chains, semi-chisel chains deliver steady, consistent performance that’s ideal for general-purpose cutting. They excel in situations where durability matters more than speed, such as limbing or felling smaller trees. Overall, semi-chisel chains provide reliable cutting efficiency over extended use, reducing downtime and maintenance. Their abrasion resistance ensures they maintain sharpness longer in challenging conditions, making them a popular choice for both amateur and professional users seeking dependable performance.

Ease of Maintenance

Because semi-chisel chains feature rounded cutting teeth, they are generally easier to maintain than their full-chisel counterparts. The rounded teeth resist dirt and debris buildup, reducing the need for frequent cleaning. Sharpenings are simpler and less precise, often requiring just a basic file. You won’t need to worry about delicate corners or complex angles, making regular maintenance faster. Additionally, semi-chisel chains stay sharper longer when used on softer wood, so you spend less time resharpening. If you’re looking for a chain that’s forgiving and easy to keep in top shape, semi-chisel chains are a great choice. They require less skill and effort to maintain, letting you focus more on your cutting tasks rather than chain care.

Low Profile Chains

Have you ever wondered how low profile chains differ from standard chainsaw chains? These chains are designed with a slimmer profile, making them lighter and easier to handle. Because of their reduced height, they require less power to operate, which can extend your saw’s lifespan and improve maneuverability. Low profile chains are ideal for light-duty tasks like pruning, trimming, and small woodcutting. They also tend to produce less vibration, minimizing fatigue during prolonged use. Additionally, their color accuracy can influence how clearly you see the cut line, especially in varied lighting conditions. This design also aligns with the trend toward automation in tools, making them more user-friendly for casual users. Moreover, the design simplicity of low profile chains can simplify maintenance and reduce the likelihood of mechanical issues. Their compatibility with small saws makes them a popular choice among homeowners and hobbyists. Furthermore, the lighter weight of these chains can contribute to reduced operator fatigue, especially during extended cutting sessions. However, they might not be suitable for heavy-duty or thick wood cutting, as their narrower design can be less durable under stress. Overall, low profile chains offer a great balance of efficiency and comfort for casual or occasional use.

Round Ground Chains

Round ground chains are known for their sharpness and cutting power, making them a reliable choice for demanding tasks. Their grounding technique offers benefits like smoother cuts and reduced kickback, enhancing safety and efficiency. With proper maintenance, these chains can stay durable and effective over many jobs. Additionally, using high-performance chains designed for specific tasks can further improve cutting efficiency and longevity. Proper chain tensioning is also essential to maintain optimal performance and prevent premature wear. Selecting the right chain type based on the intended application ensures optimal results and longer chain life. Regular inspection and cleaning of the chain also contribute to maintaining its cutting efficiency and extending its lifespan.

Sharpness and Cutting Power

Ever wondered what makes round ground chains excel in sharpness and cutting power? It’s their unique grinding process that creates a smooth, rounded edge, reducing friction and maintaining sharpness longer. This design allows the chain to cut through wood more efficiently, requiring less effort from you. The rounded ground surface minimizes heat buildup, which helps keep the blade sharp over extended use. Additionally, proper chain maintenance is key to sustaining optimal performance and prolonging the lifespan of your chainsaw chain. Regular lubrication further reduces friction and prevents premature wear. Using the right sharpening tools can significantly extend the interval between necessary adjustments, saving time and effort. Proper chain tension also plays a crucial role in maintaining cutting efficiency and safety. Here’s a quick comparison:

| Feature | Benefit | Impact |

|---|---|---|

| Rounded Grind | Smoother cutting edge | Less resistance, faster cuts |

| Material Quality | Durable steel for longevity | Less frequent sharpening |

| Tooth Shape | Chisel-shaped for aggressive cutting | Quicker, cleaner cuts |

| Sharpening Ease | Simple to hone with the right tools | Maintains sharpness longer |

| Cutting Power | Enhanced by reduced friction | Less energy needed |

This combination makes round ground chains a top choice for sharpness and power.

Grounding Technique Benefits

The grounding technique used in round ground chains offers several key benefits that enhance cutting performance. This design improves stability, making your cuts smoother and more precise. It also reduces vibrations, so you feel less fatigue during extended use. Additionally, this grounding method helps distribute cutting forces evenly across the chain, preventing uneven wear and extending your chain’s lifespan. Imagine:

- A steady, controlled cut cutting through tough wood.

- Reduced hand and arm fatigue after hours of use.

- A more durable chain that stays sharp longer.

Furthermore, incorporating proper maintenance practices can optimize the effectiveness of this grounding technique. Regularly checking and adjusting chain tension is crucial for maintaining consistent cutting performance, ensuring your chainsaw operates at peak efficiency. With this grounding method, your chainsaw becomes more efficient, giving you cleaner cuts and less maintenance. It’s a simple yet effective way to maximize your saw’s performance while making your work easier and safer.

Maintenance and Durability

Proper maintenance is essential to guarantee your chainsaw chain remains durable and performs reliably over time. With round ground chains, regular sharpening keeps the cutting edges effective, preventing dullness that can cause excessive wear. Always check your chain’s tension; a loose chain can lead to uneven cutting and faster damage, while a tight one reduces efficiency. Lubricate the chain frequently to minimize friction and heat, extending its lifespan. Inspect for signs of wear or damage, such as chipped or broken links, and replace components as needed. Keeping your chain clean from sap, dirt, and debris also helps maintain its integrity. By following these steps, you ensure your round ground chain stays sharp and durable, providing smooth cuts and reliable performance over many uses.

Skip Chains

What exactly are skip chains, and how do they differ from standard chains? Skip chains have a unique design where every second or third link is omitted, creating gaps in the cutting teeth. This pattern reduces weight and increases the chain’s speed, making it ideal for specific cutting tasks. Imagine a chain with:

- Larger gaps between teeth, like a picket fence.

- Fewer teeth making contact with the wood at once.

- Faster cutting action, as the chain moves more freely.

This setup allows for smoother cuts and less fatigue during prolonged use. Skip chains excel in felling or bucking large logs, where quick removal of material is essential. They’re lightweight, efficient, and tailored for demanding situations where speed outweighs the need for a fine finish.

Double Guard Chains

Double Guard Chains are designed to provide extra protection and durability during heavy-duty cutting tasks. They feature an additional metal guard that shields the chain and bar, reducing kickback risk and enhancing safety. This makes them ideal for demanding jobs, like felling large trees or cutting thick logs. Their reinforced design also extends chain life, minimizing wear and tear.

| Feature | Benefit |

|---|---|

| Extra metal guard | Increased safety during operation |

| Heavy-duty links | Longer-lasting performance |

| Reinforced construction | Better durability in tough cuts |

| Suitable for large tasks | Handles demanding cutting jobs |

Specialty Chains for Specific Tasks

Specialty chains are engineered to tackle specific cutting tasks more efficiently than standard chains. They’re designed with unique features to handle specialized jobs. For example, a pulping chain quickly slices through softwood to maximize pulp production. A brush cutter chain is built with extra durability to cut through thick brush and dense foliage. Lastly, a limb pruning chain offers precise, clean cuts ideal for trimming branches. As you use these chains, imagine:

Specialty chains deliver precise, efficient cuts tailored to specific forestry tasks.

- The pulping chain devouring logs with minimal effort, leaving smooth surfaces.

- The brush cutter chain slicing through tangled brush and dense undergrowth effortlessly.

- The pruning chain making clean, precise cuts on delicate branches without damage.

These specialized chains optimize performance for specific tasks, saving you time and effort while improving safety and efficiency.

Anti-Vibration Chains

If you frequently use a chainsaw for prolonged periods, reducing operator fatigue is essential, and anti-vibration chains can help achieve that. These chains are designed to minimize vibrations transferred to your hands and arms, making cutting more comfortable and less tiring. They feature special design elements, like dampening components that absorb shocks.

| Feature | Benefit |

|---|---|

| Vibration Dampening | Reduces fatigue and discomfort |

| Enhanced Stability | Improves control and safety |

| Longer Chain Life | Less wear from vibrations |

| User Comfort | Allows longer, more effective use |

Choosing anti-vibration chains can improve your experience, especially during long cutting sessions, helping you work efficiently without sacrificing comfort.

Frequently Asked Questions

Which Chain Type Is Best for Cutting Hardwoods?

When choosing a chain type for cutting hardwoods, you should opt for a full chisel chain. It’s designed to handle tough, dense wood efficiently, providing a cleaner cut and faster results. Full chisel chains have sharp, squared-off teeth that remove material quickly, making them ideal for hardwoods. You’ll find that this type of chain reduces effort and increases productivity, so your cutting tasks become much easier and more effective.

How Often Should Chains Be Sharpened for Optimal Performance?

You should sharpen your chainsaw chain regularly to maintain ideal performance. Usually, it’s best to sharpen after every few hours of cutting or when you notice reduced cutting efficiency, such as increased effort or dull cuts. Check the chain frequently for dull or chipped teeth, and sharpen them as soon as you see signs of dullness. Proper maintenance ensures safer, faster, and more efficient cutting, saving you time and effort.

Are There Chains Designed Specifically for Professional or Occasional Use?

Imagine you’re tackling a large project and wonder if your chainsaw’s chain suits your needs. Yes, some chains are designed specifically for professional use, like those with thicker, more durable links that handle heavy-duty cutting all day long. Conversely, occasional users often prefer lighter, more manageable chains. Choosing the right chain type depends on your frequency of use and cutting demands, ensuring safety and efficiency for every job.

How Does Bar Length Influence Chain Selection?

When choosing a chainsaw chain, bar length plays a vital role. If you have a longer bar, you’ll need a chain with more drive links to fit properly and cut efficiently. Shorter bars require smaller chains. Matching your bar length with the correct chain guarantees safe operation and peak performance, preventing chain slippage or kickback. Always check the manufacturer’s recommendations to select the right chain for your specific bar length.

What Safety Features Do Different Chains Offer?

Think of chains with safety features as loyal guardians for your cutting tasks. Different chains offer safety features like low-kickback designs, chain brakes, and safety tips that protect you from accidents. These features act like a shield, reducing the risk of injury during operation. Always check for safety features before choosing a chain, and remember, a well-protected chainsaw keeps your work safe and efficient.

Conclusion

Understanding the different chainsaw chain types helps you choose the right one for your tasks. Did you know that using the proper chain can increase cutting efficiency by up to 30%? Whether you need full chisel for fast cuts or low profile for lightweight jobs, selecting the right chain makes your work safer and more effective. Keep these options in mind, and you’ll be equipped to tackle any project with confidence.