To sharpen your chainsaw correctly, focus on maintaining the manufacturer’s recommended angles, typically between 25° and 35°. Use proper tools like guides and gauges to keep your angles consistent, ensuring smoother cuts and longer chain life. Avoid common mistakes like over- or under-sharpening, which can dull the chain faster. If you want to master accurate, safe sharpening techniques and learn how to check and adjust angles properly, there’s more to discover ahead.

Key Takeaways

- Proper filing angles typically range from 25° to 35°, depending on chain manufacturer specifications and wood type.

- Using sharpening guides and angle gauges ensures consistent, accurate angles during each sharpening session.

- Maintaining uniform angles across all teeth improves cutting efficiency, safety, and chain lifespan.

- Deviating from recommended angles causes inefficient cuts, increased dulling, and potential safety hazards like kickback.

- Regularly verifying and adjusting angles with the right tools helps demystify sharpening and optimizes chain performance.

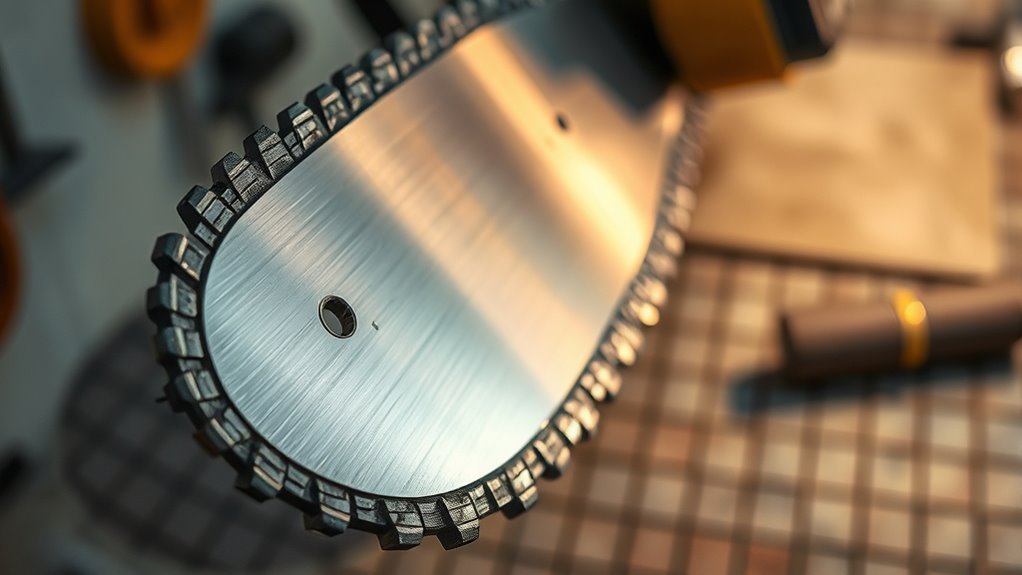

Understanding the Basics of Chain Geometry

Have you ever wondered what makes a chainsaw cut efficiently? It all comes down to chain geometry. The key elements are the angle of the cutting teeth, the depth gauge, and the height of the cutters. The cutting teeth are designed with specific angles that influence how the chain bites into wood. A proper angle ensures smooth, fast cuts without overworking the engine. The depth gauge controls how much wood each tooth removes, affecting efficiency and safety. Meanwhile, the height of the cutters determines the size of the chips and the cutting speed. Understanding these basics helps you maintain sharpness and optimize performance. When you grasp how chain geometry works, you can make informed adjustments that improve cutting efficiency and extend your chain’s lifespan. Additionally, maintaining correct sharpness and alignment is essential for achieving the best results and prolonging the life of your chainsaw components. Proper refrigerant management and regular maintenance also contribute to optimal operation and safety. Proper chain tension and lubrication play vital roles in ensuring consistent cutting performance and safety during operation. Regularly inspecting these aspects allows for better chainsaw maintenance, which ultimately enhances cutting performance and safety.

The Importance of Proper Filing Angles

Ensuring your chainsaw cuts efficiently hinges on maintaining the correct filing angles, as even small deviations can significantly impact performance. Proper angles ensure the chain sharpens evenly, reduces kickback, and prolongs chain life. If angles are off, you might notice increased effort, rough cuts, or faster dulling. To get it right:

- Maintain the manufacturer’s recommended filing angle for your chain.

- Use consistent angles on each cutter to ensure even cutting.

- Regularly check your file’s position during sharpening.

- Avoid over- or under-filing, which can weaken the cutter or reduce cutting efficiency.

- Paying attention to tooth geometry is crucial for optimal cutting performance and safety. Additionally, understanding NLP’s impact on customer experience can help businesses tailor their support and improve user satisfaction when dealing with products or services related to chainsaw maintenance. Properly maintaining filing angles can also prevent unnecessary wear on your chainsaw components, saving you time and money in the long run.

Filing at the correct angle maximizes cutting power and safety. It’s a small step with a big impact on your chainsaw’s performance, so pay close attention to the proper angles every time you sharpen.

Common Mistakes in Setting Cutting Angles

Setting your chainsaw’s cutting angles incorrectly is a common mistake that can compromise both safety and performance. When you don’t pay attention to the angle, your chainsaw may cut unevenly or become difficult to control. Too steep of an angle can cause the chain to bind or dull quickly, while too shallow may reduce cutting efficiency. Rushing the setup process or guessing can lead to inconsistent angles that harm your saw’s performance. It’s also easy to overlook the importance of maintaining the same angle on all cutters, which results in uneven cuts. Properly setting your angles ensures safer operation, better cutting results, and longer chain life. Additionally, understanding the optimal tuning options for your chainsaw can further enhance its cutting ability and durability.

How to Measure and Adjust Your Sharpening Angles

To properly measure and adjust your chainsaw’s sharpening angles, start by selecting the right tools, such as a sharpening guide or a protractor. These tools help guarantee accuracy and consistency. First, position the guide against the chain’s cutter, aligning it with the desired angle. Use a protractor if needed to double-check the angle’s measurement. When adjusting, carefully tilt the file or guide to match the target angle, maintaining steady pressure. Keep these tips in mind:

- Always verify the existing angle before making adjustments

- Use consistent pressure during filing for even sharpening

- Recheck the angle after each pass

- Mark the chain if needed to track progress

- Remember that proper vetted tools and techniques can significantly improve your sharpening results. Additionally, understanding the cybersecurity aspects of your tools and processes can help prevent disruptions during maintenance routines. Properly maintaining your equipment, including understanding the safety guidelines, ensures safer and more effective sharpening sessions. Accurate measurement and adjustment keep your chainsaw cutting efficiently and safely, and being aware of regional resources can help you find expert assistance if needed. Regularly checking your equipment for wear and tear can also extend its lifespan and maintain optimal performance.

Tools Needed for Accurate Angle Maintenance

To keep your chainsaw blades at the correct angle, you’ll need some essential tools. Sharpening guide tools help you maintain consistency, while precision angle gauges guarantee accuracy. Proper filing equipment completes the setup, making sure your blades stay sharp and aligned. For optimal results, understanding the ideal sharpening angles ensures your chainsaw performs at its best. Additionally, using comfort-enhancing tools such as ergonomic files can reduce fatigue during maintenance. Regular practice with these tools can also improve your overall chainsaw maintenance skills and efficiency. Incorporating hackathon-inspired collaboration techniques can further streamline your sharpening process and troubleshooting efforts.

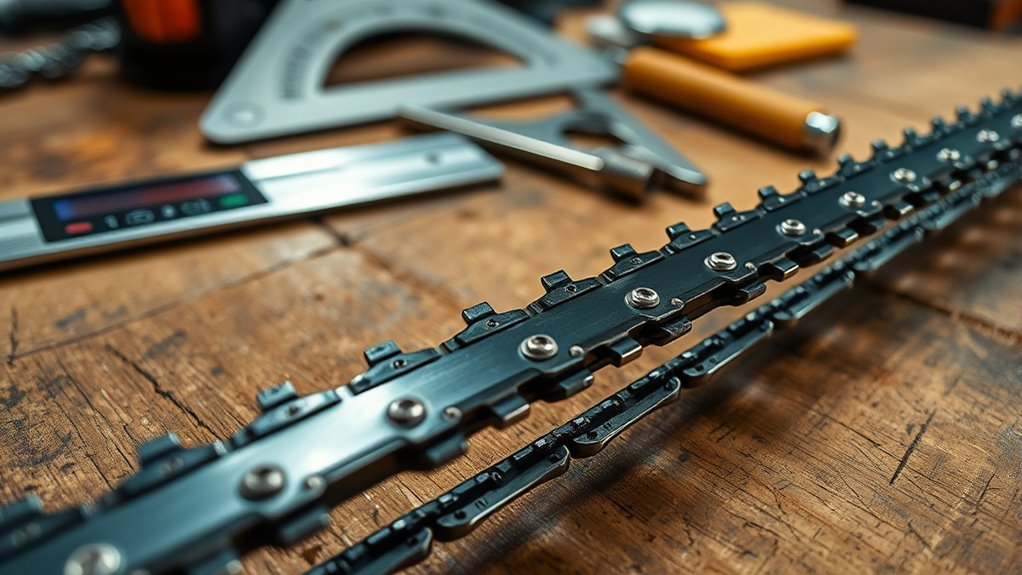

Sharpening Guide Tools

Ever wondered how to guarantee your chainsaw blade stays at the perfect sharpening angle? Using the right guide tools makes all the difference. These tools help you maintain consistent angles, ensuring effective cuts and longer chain life. A sharpening guide typically includes a jig or guide bar that attaches securely to your chainsaw or files, providing a fixed angle to follow. You might also use an angle guide block for quick adjustments, or a clamping system that holds the chain in place during sharpening. Some guides are adjustable, allowing for precise angle settings tailored to your chain. To get started, consider these essential tools:

- Fixed-angle sharpening guide

- Adjustable angle guide block

- Clamping system for stability

- Compatibility with your chainsaw model

Precision Angle Gauges

Precision angle gauges are essential tools that guarantee your chainsaw blades are sharpened at the exact angles required for ideal cutting performance. They provide a quick and accurate way to set and verify the correct filing angles, ensuring consistency across every sharpening. With these gauges, you can easily measure the existing angles on your chain, making adjustments simple and precise. They’re especially useful if you’re new to sharpening or working with different chains, helping you avoid common mistakes like over- or under-sharpening. Most gauges are adjustable and compatible with various chain types, allowing you to maintain the proper angles effortlessly. Using a precision angle gauge ensures your chainsaw cuts smoothly, efficiently, and safely, extending the life of your chain and improving your overall work quality.

Proper Filing Equipment

Having the right filing equipment is vital for maintaining accurate sharpening angles on your chainsaw. Proper tools ensure you can achieve consistent, precise results every time. First, you’ll need a high-quality round file that matches your chain’s pitch—this is essential for proper cutting. Next, a flat file helps level the depth gauges for maximum performance. A filing guide or jig ensures you maintain the correct angle during sharpening, preventing uneven edges. Additionally, a pair of gloves protects your hands and provides a better grip. Using the right equipment makes the process safer and more efficient, helping you keep your chainsaw in top condition with minimal effort. Proper tools are the foundation for precise, consistent sharpening angles.

Step-By-Step Guide to Sharpening With Correct Angles

To sharpen your chainsaw correctly, you need to start by choosing the right angle for your chain. Then, use proper sharpening tools to maintain your technique consistent. Following these steps ensures a sharp, effective cut every time.

Choosing the Right Angle

Choosing the correct angle is crucial for effectively sharpening your chainsaw chain. The right angle ensures maximum cutting performance and prolongs chain lifespan. First, check your chain’s manufacturer’s recommended angle, usually between 25° and 35°. Next, consider the type of wood you cut; softer wood may need a slightly different angle than hardwood. Keep in mind the chain’s current condition—dull or damaged chains might require adjustments. Finally, stay consistent with your angle throughout sharpening to maintain proper tooth geometry.

Remember these key points:

- Follow manufacturer’s recommended sharpening angle

- Adjust for different wood types

- Maintain consistency for each tooth

- Regularly verify your angle during sharpening

Using Proper Sharpening Tools

Using proper sharpening tools is essential to achieve accurate angles and restore your chainsaw’s cutting efficiency. You need the right tools to ensure precise sharpening and avoid damaging the chain. A files guide, round file, flat file, and a magnifying glass are key. Select a file size matching your chain’s pitch. Use a file guide to maintain consistent angles and steady strokes. Here’s a quick overview:

| Tool | Purpose | Tip |

|---|---|---|

| Round File | Sharpening the top of the tooth | Match file size to chain pitch |

| Flat File | Leveling the depth gauge | Keep flat for even wear |

| File Guide | Maintaining correct angles | Secure guide for accuracy |

Using these tools correctly guarantees your chainsaw cuts smoothly and lasts longer.

Maintaining Consistent Technique

Maintaining a consistent sharpening technique is essential for ensuring your chainsaw performs efficiently and safely. When you stick to the same angle and pressure, your chain edges stay uniform, reducing the risk of uneven cuts or kickback. To keep your technique steady, focus on these key points:

- Use a guide or jig to maintain the correct angle every time

- Apply consistent pressure throughout each stroke

- Sharpen at a steady pace, avoiding rushed motions

- Regularly check your angle with a protractor or gauge

Tips for Maintaining Consistent Sharpening Angles Over Time

To make certain your chainsaw blade stays sharp and cuts effectively, maintaining a consistent sharpening angle over time is vital. One of the best ways is to use a guide or jig designed for chainsaw sharpening. This tool ensures you keep the same angle with each pass, reducing errors. Mark your original angle with a marker before sharpening, so you can double-check your progress. Regularly inspect your file or grinder for wear, and replace it when needed to keep the angle precise. Develop a routine, like sharpening after every few uses, to build muscle memory. Keep your work area well-lit, and take your time to stay consistent. Over time, these habits help you maintain the ideal angle, guaranteeing maximum cutting performance.

Frequently Asked Questions

How Often Should I Re-Sharpen My Chainsaw Chain?

You should re-sharpen your chainsaw chain whenever it starts to cut less efficiently or you notice increased effort. Generally, every few uses or after about 8 hours of cutting, check the teeth for dullness. Sharpens should be quick and easy, so don’t wait until the chain is completely dull, which can cause damage. Regularly inspecting and maintaining your chain keeps it sharp and extends its lifespan.

Can I Sharpen My Chain Without Professional Tools?

You can sharpen your chainsaw chain without professional tools, but it’s like trying to tune a fine instrument with a butter knife. Use simple tools like a round file and a guide to keep the angle consistent. Make sure to wear safety gear and follow proper sharpening techniques. While professional tools make it easier, careful manual sharpening can do the job if you’re patient and precise, keeping your saw cutting smoothly.

What Signs Indicate My Chain Needs Sharpening?

You’ll know your chain needs sharpening when it starts to cut slowly or unevenly, requiring more effort. If the saw produces excessive vibration, burns the wood, or produces frayed or chipped cuts, it’s time to sharpen. You might also notice a dull smell or smoke. Regularly check the chain’s teeth for dullness or damage, and sharpen it promptly to maintain efficient, safe cutting performance.

How Does Chain Pitch Affect Sharpening Angles?

Your chain pitch impacts sharpening angles because it determines the size and spacing of the teeth. A larger pitch requires a different angle than a smaller one to make certain of effective cutting. When sharpening, you need to match the angle to the chain’s pitch to maintain proper performance and safety. If you use the wrong angle, the chain won’t cut efficiently, and it might wear out faster. Always check your chain’s pitch before sharpening.

Are There Differences in Angles for Different Types of Chains?

Different chains demand diverse, deliberate, and distinctive sharpening angles. You’ll find that professional, punchy, and precise chainsaw chains often require specific angles for ideal operation. For example, skip chains might need a different angle than full-chisel varieties. You must match the angle to the chain’s type, ensuring each cut is smooth, sharp, and safe. Pay attention to manufacturer instructions, and you’ll keep your chains cutting cleanly and lasting longer.

Conclusion

Mastering your chainsaw’s sharpening angles is like tending a delicate garden—each precise cut nurtures its strength and vitality. When you understand and maintain the correct angles, you’re cultivating a tool that’s sharp, reliable, and ready to cut through anything. Think of your sharpening routine as tending to a hidden treasure within your saw—your skill and attention reveal its full potential. Keep honing those angles, and your chainsaw will serve you faithfully, like a trusted partner in every cut.