Each day, you should inspect hydraulic fluid levels, checking for leaks or damage to hoses and fittings. Clean the splitting wedge and blade to prevent debris buildup, and lubricate moving parts to keep everything functioning smoothly. Test safety features like emergency stops and guards, and make certain your work area is free of debris. Verify power cords are intact, and check engine oil levels if applicable. Following this routine will help maximize safety and efficiency. For more detailed tips, keep exploring further.

Key Takeaways

- Clear debris and obstructions from the workspace to ensure safety and smooth operation.

- Inspect hydraulic fluid levels, hoses, seals, and check for leaks or damage.

- Verify power cords, extension cords, and electrical connections are intact and functional.

- Check engine oil levels (if applicable) and tighten all bolts and fasteners.

- Test safety features, shields, and control responses to confirm proper functioning.

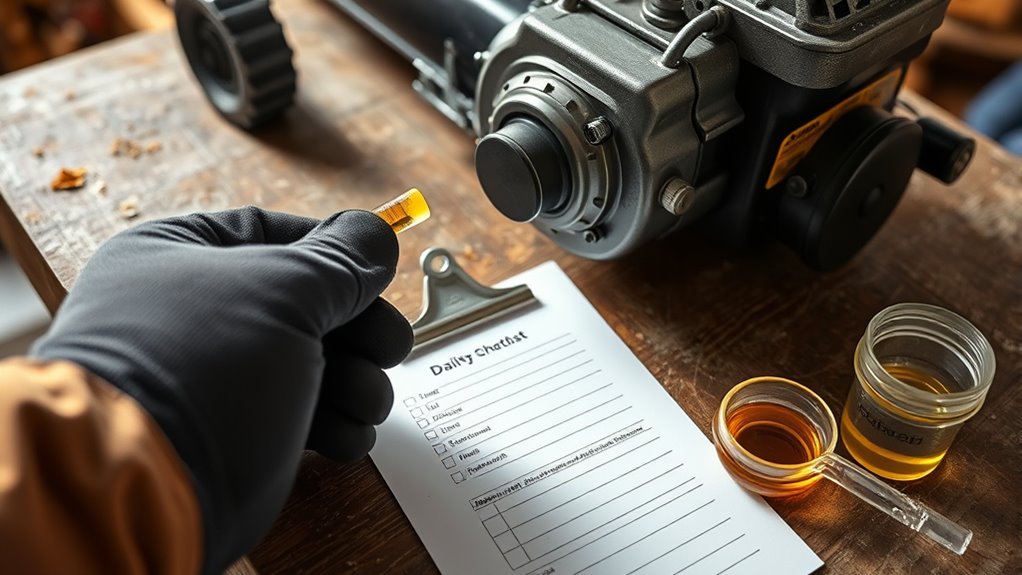

Inspect Hydraulic Fluid Levels

Before using your log splitter each day, verifying the hydraulic fluid levels is vital. Start by locating the hydraulic fluid reservoir, usually marked with a cap or dipstick. Confirm the machine is on a level surface for an accurate reading. Remove the cap and check the fluid level against the marked minimum and maximum indicators. If the fluid is below the recommended level, add the appropriate hydraulic fluid specified in your owner’s manual. Avoid overfilling, as excess fluid can cause leaks or damage. Use a clean funnel to prevent contamination. Regularly checking the fluid level helps maintain optimal pressure and performance. Proper maintenance is essential to ensure your equipment operates reliably and safely. Keep a record of your checks to track any fluid consumption over time, ensuring your log splitter operates smoothly and efficiently. Additionally, inspecting the hydraulic system periodically can help identify potential issues before they lead to costly repairs. Regular inspection of hydraulic components can prevent system failure and extend the lifespan of your equipment.

Check for Leaks and Damage

Inspecting your log splitter for leaks and damage is essential to guarantee safe and efficient operation. Regular checks help prevent costly repairs and ensure your equipment works reliably. Look closely at hydraulic hoses, fittings, and seals for any signs of fluid leaks or cracks. Examine the frame and splitting wedge for dents, rust, or warping. Tighten loose bolts or nuts promptly. Keep an eye on the control valves and hydraulic cylinder for signs of wear or leaks. Address issues immediately to avoid further damage. Staying aware of equipment safety and maintenance best practices can extend the lifespan of your log splitter. Properly maintaining hydraulic fluid levels is vital for optimal performance and safety. Regularly inspecting hydraulic components can help identify early signs of wear before they lead to major malfunctions. Additionally, monitoring system pressure and ensuring all connections are secure can prevent operational failures. Performing routine visual inspections can also catch potential problems before they escalate. Use the table below as a quick reference to identify common problems and solutions:

| Issue | Solution |

|---|---|

| Hydraulic fluid leaks | Tighten fittings or replace seals |

| Cracked or bent wedge | Replace or repair the wedge |

| Loose bolts or nuts | Tighten or replace hardware |

| Rust or corrosion | Clean and apply protective coating |

| Visible dents or warping | Repair or replace damaged parts |

Clean the Splitting Wedge and Blade

Regularly cleaning the splitting wedge and blade helps maintain their effectiveness and extends their lifespan. After each use, wipe off any wood debris, sap, or dirt with a clean cloth. For stubborn residue, use a wire brush or a scraper to remove build-up carefully, avoiding damage to the metal. Check for any rust spots and treat them with a rust remover or a light coat of oil to prevent corrosion. Confirm the wedge and blade are dry before storing the splitter. Keeping these parts clean not only guarantees smoother operation but also reduces the risk of jams or inefficient splitting. Proper maintenance practices can significantly enhance the longevity of your equipment. A quick daily clean will keep your log splitter in prime condition, ready for the next task. Additionally, inspecting for wear and tear regularly helps identify potential issues early, ensuring safety and optimal performance. Incorporating routine inspections into your maintenance routine can further prevent unexpected breakdowns and improve overall projector longevity. Regularly applying lubrication to moving parts can also reduce friction and wear, contributing to smoother operation.

Lubricate Moving Parts

To keep your log splitter operating smoothly, it’s essential to lubricate all moving parts regularly. Proper lubrication reduces friction, prevents wear, and extends the equipment’s lifespan. Start by applying a high-quality grease or oil to key components. Focus on the hydraulic ram, pivot points, and the drive shaft. Use a spray lubricant for hard-to-reach areas, ensuring even coverage. Check your owner’s manual for recommended lubrication points and intervals. Keep an eye out for signs of dryness or squeaking during operation. Regular lubrication not only improves performance but also minimizes the risk of breakdowns. Additionally, understanding GMC tuning techniques can help you optimize your vehicle’s performance and ensure your equipment runs efficiently. Applying proper maintenance practices can significantly prolong the life of your log splitter. Remember, consistent maintenance is key to keeping your log splitter reliable and ready for each use. Keeping detailed records of your lubrication schedule can also help maintain optimal equipment longevity.

Test Safety Features and Emergency Stops

Ensuring your safety features and emergency stops are functioning correctly is essential before operating your log splitter. Start by testing each safety switch and interlock system to confirm they activate when engaged. Press the emergency stop button and verify the machine halts immediately, preventing any operation. Check that safety shields and guards are in place and secure, ensuring they move freely and block access to moving parts. Confirm that the control levers and buttons respond properly and that the safety mechanisms disable the machine if you release or move them unexpectedly. Regularly testing these features guarantees they will work effectively during operation, reducing the risk of accidents. Always perform these checks prior to each use to maintain a safe working environment.

Examine Hydraulic Hoses and Fittings

Have you examined the hydraulic hoses and fittings lately? Regular checks ensure your log splitter functions safely and efficiently. Look for signs of wear, such as cracks, leaks, or bulges in the hoses. Tighten any loose fittings to prevent leaks and maintain pressure. Check for corrosion or rust that could weaken connections. Ensure all fittings are secure and free from damage. Also, examine the fittings for leaks or drips, which indicate potential issues.

Regularly inspect hydraulic hoses and fittings for wear, leaks, or corrosion to keep your log splitter running safely and smoothly.

- Inspect hoses for cracks, leaks, or bulges

- Tighten loose fittings and connections

- Check for corrosion or rust

- Look for leaks or drips at fittings

Remove Debris From the Work Area

Keeping your work area clear of debris is essential for safe and efficient operation. Remove wood chips, splinters, and any leftover bark that may have accumulated around the log splitter. Clear away fallen branches, loose tools, and other obstructions that could cause tripping hazards or interfere with the machine’s movement. Use a broom or leaf blower to quickly sweep the area, ensuring nothing is left behind. Keeping the workspace tidy reduces the risk of accidents and helps you spot potential issues early. Regularly cleaning the area also prevents debris from getting caught in moving parts or clogging vents. A clean work zone enhances safety, improves your workflow, and prolongs the lifespan of your log splitter.

Verify Power Source and Cord Condition

Before operating your log splitter, you should verify that the power source is ready and the cord is in good condition. Check the power outlet to ensure it’s functioning properly and provides a stable connection. Examine the extension cord or power cord for any cuts, frays, or exposed wires that could cause shorts or shocks. Make sure the plug is secure and fits tightly into the outlet. Avoid using damaged cords, as they pose safety risks and can lead to equipment failure. Regularly inspecting the cord and power source helps prevent accidents and ensures smooth operation. If you notice any issues, replace or repair cords immediately before use. Staying vigilant with your power setup keeps your work safe and efficient.

Ensure Proper Oil Levels in the Engine (If Applicable)

Ensuring proper oil levels in the engine is essential for the smooth operation and longevity of your log splitter. Start by turning off the engine and letting it cool down to avoid spills or burns. Locate the oil fill cap or dipstick, usually near the engine. Remove the cap and wipe the dipstick clean, then insert it back without screwing it in. Pull it out again to check the oil level; it should be between the minimum and maximum marks. If the oil is low, add the recommended type and amount of oil gradually. Avoid overfilling, as excess oil can cause leaks or engine damage. Regularly checking and maintaining correct oil levels helps prevent engine failure and keeps your log splitter running efficiently.

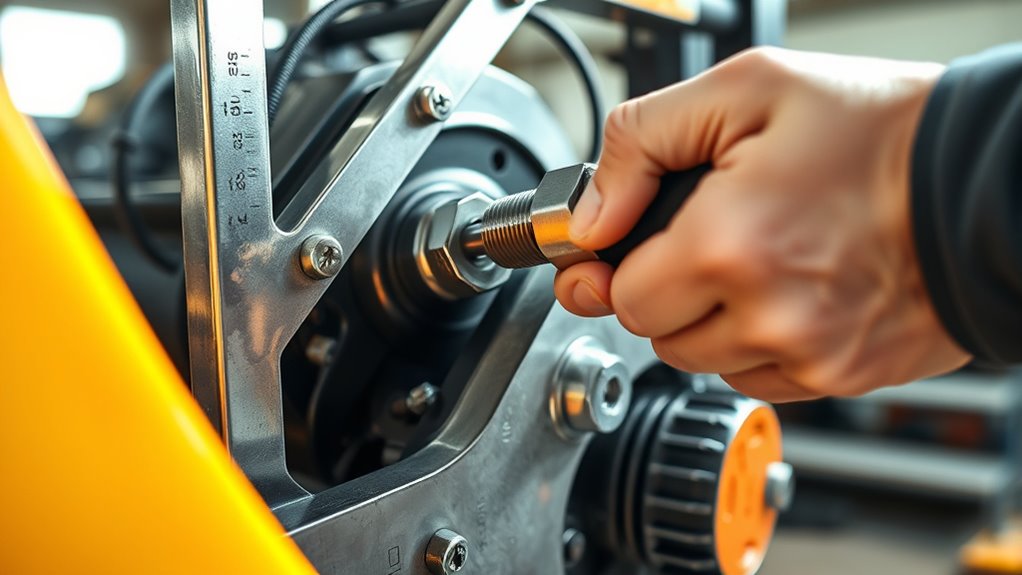

Review and Tighten Bolts and Fasteners

Regularly review all bolts and fasteners on your log splitter to prevent equipment failures. Loose components can cause unsafe operation or damage. Take a few minutes each day to inspect critical areas and ensure everything is secure. Use a wrench or screwdriver to tighten any loose bolts or nuts. Check fasteners on the hydraulic lines, engine mounts, and splitting wedge. Pay attention to signs of wear or corrosion, which may require replacing fasteners.

- Tighten bolts on the splitting wedge

- Secure hydraulic line fittings

- Check engine mounting bolts

- Inspect fasteners for corrosion or damage

Frequently Asked Questions

How Often Should I Perform a Full Maintenance Check on My Log Splitter?

You should perform a full maintenance check on your log splitter at least once a year or after heavy use. Regular inspections help identify issues early, ensuring safe and efficient operation. Always check hydraulic fluid levels, inspect for leaks, and examine blades and safety features. If you notice any irregularities or if the splitter hasn’t been used for a while, it’s wise to do a thorough maintenance to keep it in top shape.

What Are Signs That Indicate Hydraulic Fluid Needs Replacing?

You’ll know hydraulic fluid needs replacing if you notice the log splitter isn’t operating smoothly or makes unusual noises. Sluggish performance, increased effort to split wood, or visible contamination like dirt or foam on the fluid are clear signs. Also, if the fluid appears dark or has an burnt smell, it’s time for a change. Regularly check the fluid levels and condition to keep your splitter running efficiently.

Can I Use Any Lubricant on the Moving Parts, or Is Specific Type Required?

You might think any lubricant will do, but using the right one makes a difference. You need a lubricant specifically designed for log splitters to guarantee smooth operation, protect against wear, and prevent damage. Using the correct lubricant helps you avoid costly repairs, keeps your equipment running efficiently, and extends its lifespan. Always check the manufacturer’s recommendations to choose the best lubricant for your log splitter’s moving parts.

How Do I Safely Dispose of Old Hydraulic Fluid and Oils?

When disposing of old hydraulic fluid and oils, you should never pour them down drains or onto the ground. Instead, collect the used fluids in a sealed container and take it to a recycling center or authorized disposal facility. Check local regulations, as they often have specific guidelines. Proper disposal prevents environmental contamination and keeps you safe. Always wear gloves and protective gear when handling used fluids.

Are There Recommended Safety Precautions for Winterizing the Log Splitter?

When winterizing your log splitter, you should take safety precautions to prevent accidents and damage. Wear protective gloves and eye gear to avoid contact with residual hydraulic fluid. Make sure the machine is turned off and unplugged before working on it. Clear the area of debris and keep tools organized. Ventilate the workspace if you’re using chemical treatments. Following these steps keeps you safe during winterization.

Conclusion

By inspecting the hydraulic fluid, checking for leaks, cleaning the wedge, lubricating parts, testing safety features, removing debris, verifying power sources, guaranteeing proper oil levels, and tightening bolts, you keep your log splitter in top shape. Keeping everything in check, preventing issues, and maintaining safety become simple routines. Follow this checklist daily to ensure reliable operation, extend your equipment’s lifespan, and work confidently knowing your log splitter is safe, efficient, and ready whenever you need it.