To bleed air from hydraulics without guesswork, start by checking and topping up the fluid with clean, appropriate fluid, ensuring there are no contaminants. Begin at the highest point of the system and work downward, opening bleed valves while gently pumping controls. Watch for air bubbles rising and escaping, keeping the fluid level topped off to prevent additional air entry. Once no bubbles appear, tighten fittings and verify responsiveness; more tips await if you’re ready for a smoother process.

Key Takeaways

- Start bleeding at the highest point of the system to effectively remove trapped air.

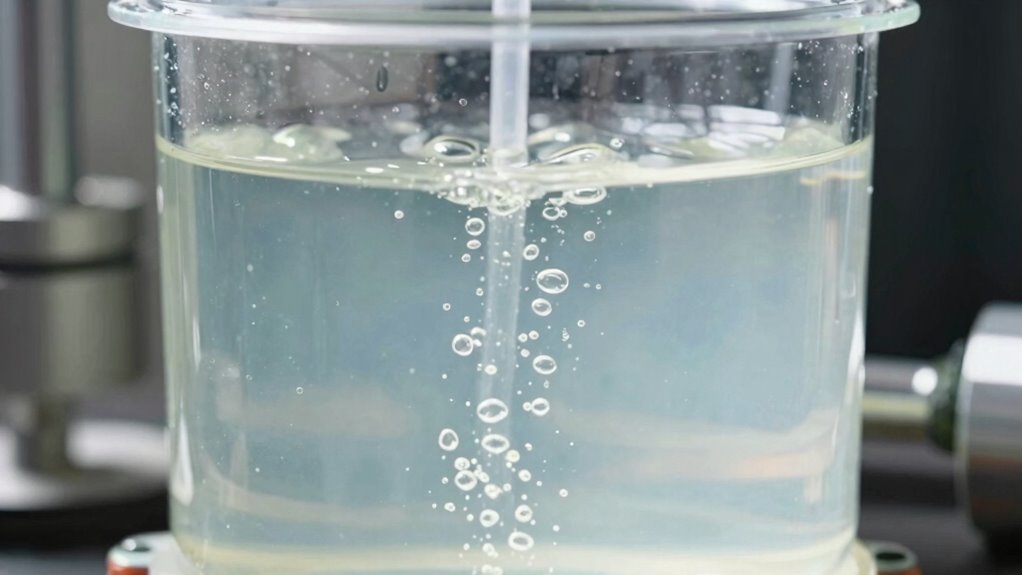

- Use transparent tubing to easily observe and confirm air bubbles escaping during bleeding.

- Maintain fluid levels topped up throughout the process to prevent air re-entry.

- Follow a systematic top-to-bottom approach, bleeding each component in sequence.

- Continue pumping and observing until no air bubbles are visible, ensuring a steady, bubble-free system.

Bleeding hydraulics is a critical process to remove air trapped in the system, which can cause spongy brakes, poor steering response, or reduced lifting power. When air enters the hydraulic lines, it creates pockets that compress more easily than fluid, leading to inconsistent performance. To effectively bleed the system, you need to understand how air entrapment affects fluid consistency and how to eliminate it thoroughly.

Air entrapment occurs when tiny bubbles are introduced during maintenance or fill-ups, or when seals and fittings aren’t tight enough. These pockets of air interfere with the smooth transmission of hydraulic pressure, which is essential for proper operation. The key is to guarantee that the hydraulic fluid remains free of air and maintains a uniform, steady flow.

Before starting, check the fluid level and top it up with the appropriate hydraulic fluid, making sure it’s clean and free from contaminants. Guarantee the fluid consistency is correct—thick or contaminated fluid can trap more air and slow down the bleeding process. You want a fluid that’s smooth, free of bubbles, and flows easily through the system. If the fluid appears cloudy or thick, replace it before proceeding.

When bleeding, always start at the highest point of the hydraulic circuit and work your way down. Open the bleed valve or fitting and gently pump the manual or power-operated controls. As you do this, you’ll notice air bubbles rising to the surface and escaping. It’s essential to keep the fluid level topped up during this process to prevent new air from entering. If you see persistent bubbles, check for leaks or loose fittings that could be reintroducing air into the system.

Patience is paramount. You might need to repeat the process several times, especially if the system has been open for a while or has experienced significant air entrapment. Keep watching for air bubbles and ensure the fluid stays consistent in appearance and flow. Using a clear hose can help you see the bubbles more easily and determine when the system is free of trapped air.

Once you stop seeing bubbles, close the bleed valve tightly, and verify the pressure or responsiveness of the system. Double-check the fluid level and top off if needed. Proper bleeding guarantees that the fluid’s consistency is uniform throughout the system, which is essential for smooth, reliable operation. Remember, a well-bled hydraulic system not only improves performance but also extends the lifespan of your components by preventing cavitation and uneven wear caused by trapped air. Additionally, understanding the role of contrast ratio can help diagnose issues related to fluid flow and pressure fluctuations that may indicate trapped air or other system problems.

Frequently Asked Questions

What Tools Are Best for Bleeding Hydraulic Systems?

You should use a hand pump or a bleeding kit with a master cylinder to effectively bleed hydraulic systems. These tools help eliminate air, preventing fluid contamination. Always monitor the process with pressure gauges to ensure proper system pressure and avoid over-pressurization. Using these tools makes bleeding straightforward, reducing errors, and making sure your hydraulic system works smoothly without guesswork.

How Often Should Hydraulic Systems Be Bled?

You should bleed your hydraulic system whenever you notice a drop in air quality or performance, typically during routine system maintenance. Regular bleeding helps remove trapped air that can cause sluggish operation or erratic pressure. Check your system’s manual for specific intervals, but generally, bleeding every few months or after maintenance tasks guarantees peak function. Staying proactive keeps your hydraulic system running smoothly and prevents costly issues down the line.

Can Improper Bleeding Cause System Damage?

Think of air entrapment like a tiny stone in a gear; it can cause grinding and damage. Improper bleeding introduces air, leading to system contamination, which accelerates wear and reduces efficiency. Left unchecked, this can cause seals to fail and damage components. You must bleed your hydraulic system properly to prevent air entrapment from causing costly repairs and ensuring your system runs smoothly without damage.

Is Manual Bleeding Suitable for All Hydraulic Setups?

Manual bleeding isn’t suitable for all hydraulic setups because it depends on your system’s pressure and the type of hydraulic fluid you’re using. If your system operates at high pressure or uses sensitive hydraulic fluid types, manual methods might be ineffective or risky. Always check your equipment specifications and fluid compatibility before attempting manual bleeding, and consider alternative methods if needed to guarantee proper air removal without damaging your system.

How to Identify Trapped Air in Complex Hydraulics?

You can identify trapped air in complex hydraulics by watching for air bubbles in the fluid or inconsistent movement. Check for hydraulic leaks, which often indicate air pockets forming around seals or fittings. If you notice sluggish response, spongy operation, or erratic performance, trapped air is likely the cause. Use visual inspections and listen for unusual sounds to pinpoint where air might be hiding, then proceed with bleeding to remove it effectively.

Conclusion

Bleeding air from your hydraulic system doesn’t have to be complicated. With the right steps, you can do it quickly and confidently. Did you know that improper bleeding can cause up to 30% loss in system efficiency? That’s a big impact you can avoid with proper technique. Keep your system running smoothly by bleeding air correctly—saving time, reducing costs, and ensuring safety. Don’t guess—just follow these simple tips and keep your hydraulics performing at their best.