You should replace your flywheel if you notice persistent vibrations, difficulty shifting gears, or unusual noises when engaging the clutch. Signs like a burning smell, overheating, or visible damage such as cracks or grooves also indicate it’s time for a switch. If your vehicle stalls, loses power, or your clutch slips unexpectedly, these are strong warning signs. There’s more to contemplate, and understanding these details can help keep your car running smoothly.

Key Takeaways

- Visible cracks, hot spots, scoring marks, or deep grooves indicate the need for replacement.

- Persistent vibrations, clutch slipping, or difficulty shifting suggest flywheel issues requiring attention.

- Overheating signs like surface discoloration or warping warrant replacing the flywheel.

- Symptoms such as engine stalling, erratic engagement, or abnormal noise point to potential failure.

- Regular inspections help detect surface damage early, preventing costly repairs and ensuring reliable operation.

Persistent Vibrations During Operation

Persistent vibrations during operation can be a clear sign that your flywheel is failing. These vibrations often stem from issues with the flywheel material or manufacturing defects. Over time, the material can develop cracks or warping, causing uneven rotation and shaking. Manufacturing defects, such as improper balancing or flaws in the casting process, can also lead to persistent vibrations. If you notice your vehicle vibrating excessively when idling or during acceleration, it’s likely the flywheel is compromised. Ignoring these signs can cause further damage to your transmission and clutch assembly. Early inspection and replacement of a faulty flywheel restore smooth operation and prevent costly repairs down the line. Pay close attention to vibrations—they’re often your first clue that a flywheel replacement is needed. Additionally, understanding the contrast ratio of your vehicle’s components can help diagnose issues related to uneven performance or vibrations.

Difficulty Shifting Gears Smoothly

Difficulty shifting gears smoothly can indicate a problem with your flywheel, especially if the clutch feels stiff or you notice resistance when changing gears. Misalignment or surface imperfections can cause engagement issues, making gear shifts cumbersome. If you experience persistent difficulty, it might be time to contemplate flywheel resurfacing to restore a smooth surface. Proper gear alignment is vital, as misalignment can lead to uneven contact and shifting problems. Additionally, a warped or damaged flywheel can prevent the clutch from disengaging fully, causing resistance. Regular inspection and maintenance can help identify these issues early. If symptoms persist after adjusting the clutch, replacing or resurfacing the flywheel could be necessary to guarantee smooth gear transitions and prevent further damage. Considering Gold IRA rollovers as part of your long-term financial plan emphasizes the importance of proactive maintenance—just as regular vehicle inspections can prevent costly repairs, diversifying retirement investments can secure your future against market fluctuations.

Unusual Noises When Engaging the Clutch

If you hear chirping or squealing sounds when engaging the clutch, it could signal a problem with your flywheel or clutch components. A slipping or jerking motion during gear shifts might also indicate issues that require attention. Recognizing these unusual noises early helps prevent further damage and guarantees your vehicle runs smoothly. Regular inspection can help identify appliance maintenance needs that may contribute to mechanical problems.

Chirping or Squealing Sounds

When you hear chirping or squealing sounds when engaging the clutch, it often indicates that the flywheel or related components are wearing out or misaligned. These noises may stem from issues with the flywheel material or manufacturing defects that cause uneven surfaces or vibrations. You might notice the sound intensifies with engine speed or clutch engagement. Additionally, Mazda Tuning practices such as performance upgrades or handling modifications can influence clutch system behavior, making it especially important to address these sounds promptly.

- Worn or glazed flywheel surface

- Misaligned or damaged clutch release bearing

- Contaminated or worn clutch disc

- Manufacturing defects causing irregularities in flywheel material

These issues can lead to increased wear and further damage if ignored. Recognizing these sounds early helps prevent costly repairs and ensures your clutch system remains smooth and reliable.

Slipping or Jerking Motion

A slipping or jerking motion during clutch engagement often signals issues with the flywheel that prevent smooth power transfer. This problem can stem from a worn or damaged flywheel, often caused by the flywheel material wearing down over time. If you notice this behavior, it’s likely your flywheel needs attention. The replacement cost varies depending on the flywheel material—steel is generally cheaper, while billet or specialty materials cost more. When replacing a flywheel, consider whether the entire assembly needs replacement or just resurfacing. Ignoring these symptoms can lead to further clutch damage. If you experience slipping or jerking, it’s best to have a mechanic evaluate whether your flywheel requires replacement to restore smooth driving and avoid costly repairs later. Modern vehicle components are increasingly incorporating smart technologies, which can also help monitor and alert you to mechanical issues early on.

Burning Smell or Overheating Symptoms

A burning smell or signs of overheating are clear indicators that your flywheel might be malfunctioning. If you notice this, it’s essential to address the issue promptly to prevent further damage. Overheating often results from a slipping clutch or poor clutch adjustment, which causes excessive friction. You might also see discoloration or warping on the flywheel surface. To fix this, consider having your flywheel resurfaced to smooth out any irregularities. If the problem persists, replacing the flywheel may be necessary. Keep an eye on these symptoms and act quickly to avoid more costly repairs down the line. Proper maintenance, including regular clutch adjustment, can help prevent overheating and prolong the life of your flywheel.

Clutch Slipping or Engaging Erratically

If your clutch slips or engages unexpectedly, it’s a clear sign something’s wrong. You might notice inconsistent gear shifts or a lack of responsiveness when you press the pedal. These issues often point to wear indicators that suggest it’s time to inspect or replace your flywheel. Additionally, improper engine tuning can contribute to increased stress on the flywheel, accelerating wear.

Signs of Clutch Slippage

Clutch slippage often shows up as sudden changes in engine response, making your vehicle feel like it’s struggling to accelerate smoothly. You might notice the engine revving higher without a corresponding increase in speed. If your clutch pedal feels different—either too soft or too stiff—that’s another warning sign. The flywheel surface could be worn or damaged, causing inconsistent contact with the clutch disc. Regular maintenance and inspection of vital components like the flywheel can help prevent complete failure.

Signs of clutch slippage include:

- Engine revs rise while speed stays constant

- Difficulty accelerating in higher gears

- Burning smell from the clutch area

- Unusual clutch pedal feel or engagement point

If you notice these issues, it’s time to inspect the clutch and flywheel surface before further damage occurs.

Inconsistent Gear Engagement

When your vehicle shifts gears unexpectedly or feels like it’s slipping out of gear, it signals that the clutch may be engaging inconsistently. This could be caused by a need for proper clutch pedal adjustment, ensuring the clutch engages smoothly. If the clutch pedal feels soft or unresponsive, adjusting it can improve engagement. Additionally, inconsistent gear engagement might stem from a warped or worn flywheel, which causes uneven contact with the clutch disc. In such cases, flywheel resurfacing can restore a smooth, even surface, preventing slipping and erratic shifts. Addressing these issues promptly helps maintain proper clutch function and prevents further damage to the flywheel or clutch assembly. Ignoring inconsistent engagement can lead to more severe problems requiring flywheel replacement. Moreover, AI insights from recent technological advancements can aid in diagnosing and preventing such mechanical issues through predictive maintenance tools.

Potential Wear Indicators

As you operate your vehicle, you might notice the clutch slipping or engaging erratically, which often signals wear in the clutch components or flywheel. These symptoms are key potential wear indicators. You may experience difficulty shifting gears or sudden loss of power during acceleration. You might also hear squealing or grinding sounds when pressing the clutch. To diagnose, perform a thorough flywheel inspection for hot spots or grooves. If wear is evident, flywheel resurfacing can smooth out uneven surfaces. Ignoring these signs can lead to further damage, making replacement necessary. Keep an eye on clutch performance and consider prompt flywheel resurfacing or replacement when symptoms persist. Regular maintenance and awareness of vehicle component health can help prevent unexpected failures, ensuring your vehicle remains reliable and safe on the road.

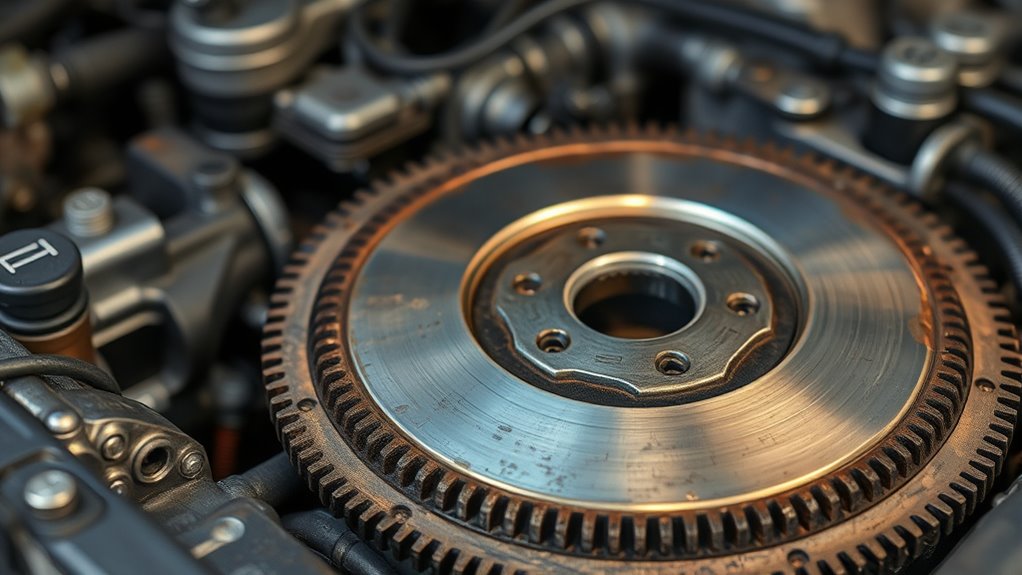

Visible Damage or Wear on the Flywheel Surface

Visible damage or wear on the flywheel surface is a clear sign that it may need replacing. During a visual inspection, look for cracks, hot spots, or scoring marks on the flywheel surface. These issues indicate that the flywheel has experienced excessive heat or wear, which can compromise its integrity. Warped or burned areas suggest overheating and potential failure. If you notice deep grooves or uneven surfaces, it’s a sign that the flywheel isn’t providing a smooth engagement. Regularly inspecting the flywheel surface helps catch problems early before they lead to more serious issues, such as clutch slipping or difficulty shifting gears. If you observe significant damage during your visual inspection, it’s time to contemplate replacing the flywheel to ensure proper vehicle operation.

Engine Stalling or Loss of Power While Driving

Engine stalling or a sudden loss of power while you’re driving often signals a failing flywheel. This can happen when the flywheel material wears down or develops cracks, disrupting the engine’s smooth operation. If your vehicle stalls unexpectedly or struggles to accelerate, it may be time to check the flywheel against manufacturer specifications. Worn or damaged flywheels can cause uneven engagement, leading to engine hesitation or stalling. Additionally, overheating or improper installation can worsen the problem. Pay attention to symptoms like rough idling or difficulty shifting gears. Regular inspection guarantees the flywheel’s integrity, and replacing it when necessary keeps your engine running efficiently and safely. Understanding the role of system security assessments can help in diagnosing underlying issues with your vehicle’s components. Remember, adhering to manufacturer specifications is vital for proper flywheel performance and longevity.

Frequently Asked Questions

How Long Does a Typical Flywheel Last Before Needing Replacement?

A typical flywheel lifespan varies depending on usage and maintenance, but generally, you can expect it to last between 100,000 and 150,000 miles. Your replacement timeline depends on signs of wear like vibrations or unusual noises. Keep an eye on these indicators, and if you notice them, it’s time to think about a replacement. Regular inspections help guarantee your flywheel’s longevity and peak performance.

Can a Flywheel Be Repaired or Only Replaced?

You might wonder if a flywheel can be repaired or if it requires replacement. Generally, flywheel repair is limited, especially if it’s cracked or severely worn. Regular flywheel maintenance can help identify issues early, but most problems usually mean replacing the flywheel. Repair options are rare and often not cost-effective. It’s best to consult a mechanic to assess whether flywheel repair is possible or if replacement is the safer, more reliable choice.

What Are the Signs of a Failing Flywheel Besides Listed Symptoms?

You might notice signs of a failing flywheel beyond clutch slipping and unusual vibrations, like difficulty shifting gears or a burning smell from your clutch area. If you experience inconsistent engine performance or a rough idle, it could indicate flywheel issues. Keep an eye out for excessive heat or noise when the clutch is engaged, as these are also early warning signs that your flywheel may be failing and need attention.

Is Replacing a Flywheel a Costly Repair?

Did you know that a flywheel replacement can cost between $300 and $1,000? Replacing a flywheel is indeed a costly repair, mainly because of labor and parts. The replacement costs vary depending on your vehicle’s make and model, and whether you need additional repairs. While it’s an investment, fixing it promptly prevents further engine damage, ultimately saving you money in the long run.

How Can I Prevent Premature Flywheel Wear?

To prevent premature flywheel wear, you should regularly check your drive shaft for any damage or misalignment, as this can put extra stress on the flywheel. Additionally, verify your clutch is properly adjusted; a poorly adjusted clutch can cause excessive slipping and wear. Avoid aggressive driving habits and have your clutch and drive shaft inspected by a mechanic to extend the flywheel’s lifespan.

Conclusion

If you ignore these warning signs, your flywheel could give out at the worst possible moment—leaving you stranded, stranded in the middle of nowhere, with a car that refuses to move. Don’t let a tiny crack or faint squeal turn into a catastrophic breakdown that costs a fortune to fix. Stay vigilant, replace your flywheel when needed, and keep your engine purring smoothly—because a failing flywheel is like a ticking time bomb for your vehicle!