When choosing the 13 best overhead beam clamp trolleys for 2026, I look for models with strong load capacities, adjustable fit for different beam sizes, and durable materials like manganese or alloy steel. Safety features like locking mechanisms and anti-drop pins are essential for reliable operation. Operational efficiency and compatibility with electric hoists also matter. If you keep exploring, you’ll discover top options that meet all these needs and guarantee safe lifting.

Key Takeaways

- Compatibility with a wide range of beam sizes and widths ensures versatile application for various industrial needs.

- High load capacities up to 6,000 lbs guarantee reliable performance in heavy-duty lifting operations.

- Durable construction from manganese or alloy steel with corrosion-resistant coatings enhances longevity and safety.

- Smooth movement features like full ball bearing wheels and swivel options enable efficient, precise maneuvering.

- Safety features such as locking mechanisms, anti-loose nuts, and collision bumpers ensure secure and reliable operation.

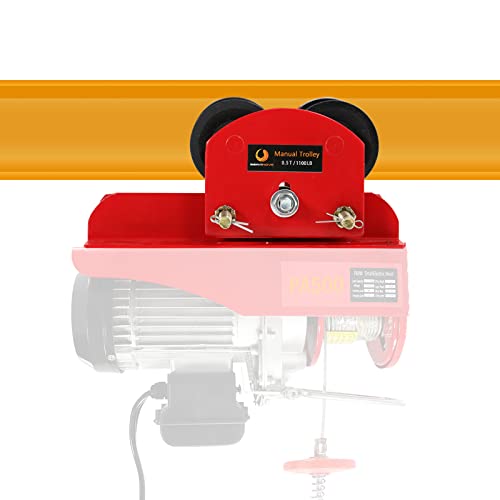

| Manual Trolley for I-Beam 2200lbs with Heavy Duty Wheels |  | Heavy-Duty Performer | Load Capacity: 2200 lbs (1 ton) | Adjustable Width Range: 2.68-4.33 in | Construction Material: Manganese steel | VIEW LATEST PRICE | See Our Full Breakdown |

| BEAMNOVA Manual Trolley for I-Beam 0.5 Ton |  | Reliable Budget Option | Load Capacity: 1102 lbs (0.5 ton) | Adjustable Width Range: 1.57-4.64 in | Construction Material: Manganese steel | VIEW LATEST PRICE | See Our Full Breakdown |

| BEAMNOVA 1 Ton Electric Trolley for I-Beam |  | Industrial Powerhouse | Load Capacity: 2204 lbs (1 ton) | Adjustable Width Range: 2.36-4.72 in | Construction Material: Manganese steel | VIEW LATEST PRICE | See Our Full Breakdown |

| BEAMNOVA 3 Ton Adjustable I-Beam Trolley |  | Adjustable Versatility | Load Capacity: 6614 lbs (3 tons) | Adjustable Width Range: 3.66-8.46 in | Construction Material: Manganese steel | VIEW LATEST PRICE | See Our Full Breakdown |

| 3 Ton Manual I-Beam Trolley with Dual Wheels |  | Heavy Load Champion | Load Capacity: 6614 lbs (3 tons) | Adjustable Width Range: 3.66-8.46 in | Construction Material: Manganese steel | VIEW LATEST PRICE | See Our Full Breakdown |

| 3″ Beam Trolley with Hardware and Drop |  | Precision Fit | Load Capacity: 200 lbs | Adjustable Width Range: Fits 5.5 in drop I-beams | Construction Material: Cast iron with steel brackets | VIEW LATEST PRICE | See Our Full Breakdown |

| VEVOR Manual Trolley for I-Beams 2 Tons |  | Robust Construction | Load Capacity: 4400 lbs (2 tons) | Adjustable Width Range: 2.5-7 in | Construction Material: Alloy steel | VIEW LATEST PRICE | See Our Full Breakdown |

| I-Beam Cable Trolley System |  | Multi-Application Flexibility | Load Capacity: 50 lbs | Adjustable Width Range: 2.75-8.25 cm (~1.08-3.25 in) | Construction Material: Steel with rust-resistant surface | VIEW LATEST PRICE | See Our Full Breakdown |

| Beam Trolley with Side Guide Rollers 1,500 lbs Capacity |  | Durable Industrial Choice | Load Capacity: 1500 lbs | Adjustable Width Range: 4-8 in | Construction Material: Cast iron | VIEW LATEST PRICE | See Our Full Breakdown |

| Manually Trolley 1 Ton Steel Beam Push Trolley |  | High Capacity Leader | Load Capacity: 2200 lbs (1 ton) | Adjustable Width Range: 3-4.6 in | Construction Material: Steel with baked enamel paint | VIEW LATEST PRICE | See Our Full Breakdown |

| BEAMNOVA Manual Trolley for I-Beam 1 Ton Capacity |  | Easy Setup | Load Capacity: 2200 lbs (1 ton) | Adjustable Width Range: 1.57-6.1 in | Construction Material: Alloy steel | VIEW LATEST PRICE | See Our Full Breakdown |

| CPROSP 3-Ton Beam Trolley with Adjustable Width |  | Secure Stability | Load Capacity: 6613 lbs (3 tons) | Adjustable Width Range: 4-8 in | Construction Material: Manganese steel | VIEW LATEST PRICE | See Our Full Breakdown |

| VEVOR Manual Trolley 2200 lbs Adjustable I-Beam |  | Heavy-Duty Efficiency | Load Capacity: 2200 lbs (1 ton) | Adjustable Width Range: 2.5-7 in | Construction Material: Alloy steel | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Manual Trolley for I-Beam 2200lbs with Heavy Duty Wheels

If you’re looking for a reliable trolley to handle heavy-duty lifting on I-beams, the Manual Trolley for I-Beam 2200lbs with Heavy Duty Wheels is an excellent choice. It supports up to 2200 pounds and fits I-beams between 50mm and 110mm wide, with adjustable flange widths from 2.68 to 4.33 inches. Made from durable manganese steel and finished with a wear-resistant coating, it offers stability and longevity. Its six-wheel system provides smooth movement over various rail types, while swivel wheels enable 360-degree turns. Lightweight yet robust, this trolley combines security, ease of use, and versatility in demanding lifting applications.

- Load Capacity:2200 lbs (1 ton)

- Adjustable Width Range:2.68-4.33 in

- Construction Material:Manganese steel

- Wheel Type:6 swivel wheels

- Safety Features:Locking nuts, anti-loose nuts

- Application Environment:Heavy-duty industrial, warehouse, outdoor, shops

- Additional Feature:Swivel 360-degree wheels

- Additional Feature:Adjustable flange width

- Additional Feature:Lightweight design

BEAMNOVA Manual Trolley for I-Beam 0.5 Ton

The BEAMNOVA Manual Trolley for I-Beam, 0.5 Ton stands out as an excellent choice for professionals needing reliable and versatile beam handling equipment. It fits standard or wide flange I-beams, accommodating beam widths from 1.57 to 4.64 inches with adjustable steel plates. Made from thick manganese steel, it offers exceptional strength and durability, enhanced by a powder-coated finish for wear resistance. The hardened steel wheels and sealed ball bearings ensure smooth operation, while the anti-loose side locking nut guarantees safety. Supporting up to 0.5 ton, it’s compatible with various electric hoists and designed for heavy-duty, frequent use.

- Load Capacity:1102 lbs (0.5 ton)

- Adjustable Width Range:1.57-4.64 in

- Construction Material:Manganese steel

- Wheel Type:Hardened steel wheels

- Safety Features:Locking nut, safety lock

- Application Environment:Heavy-duty, frequent use, industrial

- Additional Feature:Hardened steel wheels

- Additional Feature:Double-sealed ball bearings

- Additional Feature:Locking safety mechanism

BEAMNOVA 1 Ton Electric Trolley for I-Beam

For professionals seeking a reliable and heavy-duty trolley, the BEAMNOVA 1 Ton Electric Trolley for I-Beam stands out with its robust manganese steel frame and impressive load capacity. Its powder-coated finish offers excellent wear resistance, ensuring longevity. Hardened steel wheels and sealed ball bearings guarantee smooth operation under heavy loads. Compatibility isn’t an issue, as it fits standard or wide flange I-beams from 58mm to 120mm wide. With features like a side locking nut, a 2-meter power cord, remote control, and an emergency stop, it combines safety and convenience. This trolley is ideal for handling up to 1 ton on various beam configurations in industrial settings.

- Load Capacity:2204 lbs (1 ton)

- Adjustable Width Range:2.36-4.72 in

- Construction Material:Manganese steel

- Wheel Type:Dual wheels with large steel wheels

- Safety Features:Locking nut, collision bumpers

- Application Environment:Industrial, workshop, heavy-duty

- Additional Feature:Remote control included

- Additional Feature:Emergency stop switch

- Additional Feature:Adjustable beam fit

BEAMNOVA 3 Ton Adjustable I-Beam Trolley

When tackling heavy-duty lifting tasks, the BEAMNOVA 3 Ton Adjustable I-Beam Trolley stands out with its impressive load capacity and versatile fit. It adjusts to flange widths from 3.66″ to 8.46″ (93-215mm), making it compatible with various I-beams and H-beams. Made from corrosion-resistant manganese steel, it’s built for durability and can support up to 6,614 lbs (3 tons). Safety features like collision bumpers and anti-drop pins ensure secure operation. Installation is straightforward—measure, fit washers, and secure with nuts and pins. Its adaptability makes it ideal for factories, construction sites, and warehouses, handling a wide range of lifting needs.

- Load Capacity:6614 lbs (3 tons)

- Adjustable Width Range:3.66-8.46 in

- Construction Material:Manganese steel

- Wheel Type:Dual-axle wheels

- Safety Features:Safety features with anti-loose nuts

- Application Environment:Factory floors, construction, warehouse

- Additional Feature:Wide flange adjustment

- Additional Feature:Corrosion-resistant manganese steel

- Additional Feature:Collision bumpers included

3 Ton Manual I-Beam Trolley with Dual Wheels

If you’re looking for a heavy-duty trolley that handles demanding overhead lifting tasks, the Ton Manual I-Beam Trolley with Dual Wheels stands out with its impressive 3-ton capacity. Made from high-quality manganese steel, it’s built for durability and long-term use in tough environments. Its adjustable design fits flange widths from 3.66 to 8.46 inches, making it versatile for various beams. Safety features like collision bumpers and anti-drop wire pins enhance security during operation. With straightforward installation and a weight of just over 24 pounds, this trolley is reliable, easy to set up, and highly rated by users for industrial applications.

- Load Capacity:6614 lbs (3 tons)

- Adjustable Width Range:3.66-8.46 in

- Construction Material:Manganese steel

- Wheel Type:Dual wheels

- Safety Features:Hex nuts, collision bumpers, anti-drop pins

- Application Environment:Factory, construction, warehouse

- Additional Feature:Black manganese steel body

- Additional Feature:Dual-wheel design

- Additional Feature:Easy quick adjustment

3″ Beam Trolley with Hardware and Drop

The 3-inch beam trolley with hardware and a 5-1/2 inch drop is an excellent choice for those seeking reliable overhead conveyor support, especially in applications requiring precise positioning on I-beam systems. Made in the USA by Jervis B Webb, it supports up to 200 pounds per trolley, with a combined capacity of 400 pounds using a load bar. Its construction features full ball bearing wheels, forged carbon steel brackets, and triple labyrinth seals for durability. The trolley includes a standard I attachment and hardware, designed for compatibility with 5-1/2 inch drop I-beams, ensuring smooth, secure movement along your overhead system.

- Load Capacity:200 lbs

- Adjustable Width Range:Fits 5.5 in drop I-beams

- Construction Material:Cast iron with steel brackets

- Wheel Type:Full ball bearing complement wheels

- Safety Features:Sealed bearings, bumpers

- Application Environment:Industrial, heavy-duty environments

- Additional Feature:Made in the USA

- Additional Feature:Full ball bearing wheels

- Additional Feature:Drop distance of 5-1/2″

VEVOR Manual Trolley for I-Beams 2 Tons

The VEVOR Manual Trolley for I-Beams stands out for its impressive load capacity of 2 tons, making it an ideal choice for heavy-duty lifting tasks. Its adjustable width from 2.5 to 7 inches allows it to fit various I-beam and H-beam flange sizes, enhancing versatility. Constructed from heavy-duty alloy steel, it offers excellent strength, durability, and corrosion resistance. Safety is a priority, with features like a collision bumper and anti-drop wire pin. Easy to install and handle, this trolley is suitable for straight or curved beams in factories, construction sites, or warehouses. At roughly 19.5 pounds, it combines robustness with user-friendly operation.

- Load Capacity:4400 lbs (2 tons)

- Adjustable Width Range:2.5-7 in

- Construction Material:Alloy steel

- Wheel Type:2-inch wheels

- Safety Features:Locking nut, safety lock

- Application Environment:Industrial, heavy-duty applications

- Additional Feature:Upgraded 6-wheel design

- Additional Feature:Heavy-duty alloy steel

- Additional Feature:Easy installation process

I-Beam Cable Trolley System

An I-Beam Cable Trolley System stands out as an ideal choice for industrial settings requiring reliable and smooth cable transportation. Made from high-quality steel with a rust-resistant black finish, it ensures durability for heavy-duty tasks. Its design includes two embedded bearings per wheel, providing effortless and precise movement along I-beam tracks. The adjustable width, from 2.75 cm to 8.25 cm, allows compatibility with most I-beam types, making it versatile. Supporting a maximum load of 50 lbs, it’s perfect for cable transport, gantry cranes, and assembly lines. Plus, its simple operation makes manual handling quick and efficient, ideal for warehouse and factory environments.

- Load Capacity:50 lbs

- Adjustable Width Range:2.75-8.25 cm (~1.08-3.25 in)

- Construction Material:Steel with rust-resistant surface

- Wheel Type:2-inch wheels

- Safety Features:Locking nut, bumpers

- Application Environment:Factory, warehouse, factory lines

- Additional Feature:Supports cable transport

- Additional Feature:Simple manual operation

- Additional Feature:Rust-resistant surface

Beam Trolley with Side Guide Rollers 1,500 lbs Capacity

If you’re working with heavy loads up to 1,500 pounds on overhead tracks, the Beam Trolley with Side Guide Rollers offers exceptional stability and smooth operation. Made from durable cast iron with a sleek gold finish, it’s built to withstand demanding industrial environments. Its side guide rollers minimize friction, allowing effortless movement around curves, while bolted wheels make maintenance easy. Compatible with standard steel I-beams, it fits beams with tapered flanges and adjustable widths of 4, 5, and 6 inches. Whether lifting equipment, doors, or materials, this trolley provides reliable performance and versatility for various heavy-duty applications.

- Load Capacity:1500 lbs

- Adjustable Width Range:4-8 in

- Construction Material:Cast iron

- Wheel Type:Solid wheels

- Safety Features:Locking mechanism, safety lock

- Application Environment:Industrial, automotive, warehouse

- Additional Feature:Side guide rollers included

- Additional Feature:Cast iron construction

- Additional Feature:Bolted wheel design

Manually Trolley 1 Ton Steel Beam Push Trolley

For those seeking reliable manual load transportation, the Manually Trolley 1 Ton Steel Beam Push Trolley stands out with its impressive 1-ton capacity and versatile compatibility. Designed for horizontal movement by hand, it easily supports up to 2200 lbs, making it ideal for industrial, warehouse, and construction tasks. Its adjustable feature fits beam flanges from 3″ to 4.6″, accommodating standard and wide flange I-beams. Built with rugged steel side plates and coated for corrosion resistance, it includes bumper guards for durability. Easy to install and operate, this lightweight yet sturdy trolley offers a practical solution for heavy-duty manual load handling.

- Load Capacity:2200 lbs (1 ton)

- Adjustable Width Range:3-4.6 in

- Construction Material:Steel with baked enamel paint

- Wheel Type:Bumper guards, no specific wheel type specified

- Safety Features:Self-locking nuts, bumper guards

- Application Environment:Industrial, warehouse, construction

- Additional Feature:Baked enamel coating

- Additional Feature:Built-in bumper guards

- Additional Feature:Rugged steel side plates

BEAMNOVA Manual Trolley for I-Beam 1 Ton Capacity

The BEAMNOVA Manual Trolley for I-Beam stands out as an excellent choice for heavy-duty lifting tasks, thanks to its robust 1-ton load capacity and compatibility with various electric hoists. It fits standard or wide flange I-beams from 1.57 to 6.1 inches wide and features adjustable steel plates for a snug fit. Its thickened manganese steel frame and powder-coated finish guarantee durability and wear resistance. The upgraded 6-wheel design offers smooth operation on straight or tapered beams, while large steel wheels and sealed ball bearings assure reliable performance. Safety is prioritized with a side locking nut and secure locking mechanism, making it a dependable lifting tool.

- Load Capacity:2200 lbs (1 ton)

- Adjustable Width Range:1.57-6.1 in

- Construction Material:Alloy steel

- Wheel Type:All-steel wheels

- Safety Features:Anti-loose nut, safety lock

- Application Environment:Heavy-duty industrial environments

- Additional Feature:Heavy-duty alloy steel

- Additional Feature:Side locking nut

- Additional Feature:Suitable for curved beams

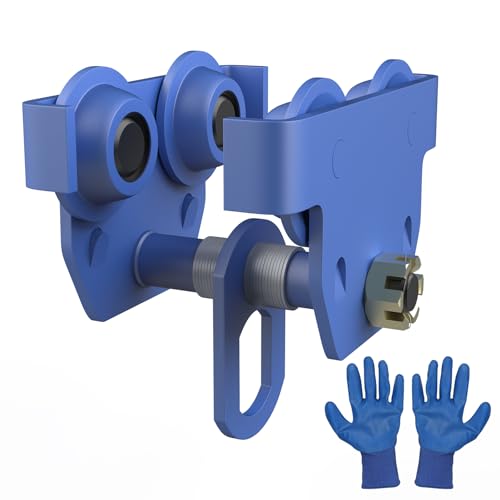

CPROSP 3-Ton Beam Trolley with Adjustable Width

Designed to handle heavy-duty lifting with ease, the CPROSP 3-Ton Beam Trolley’s adjustable width makes it an excellent choice for diverse overhead crane systems and workshop setups. It fits beams from 4 to 8 inches wide, thanks to its adjustable spacers, and requires no tools for installation—perfect for monorails, crane systems, or shop trolley rails. With a 3-ton capacity and four all-steel wheels with sealed ball bearings, it delivers smooth, stable movement on flat, tapered, straight, or curved beams. Made from durable manganese steel with a corrosion-resistant powder coating, it’s built for long-term, demanding use. Ready to operate straight out of the box, it ensures safety and reliability.

- Load Capacity:6613 lbs (3 tons)

- Adjustable Width Range:4-8 in

- Construction Material:Manganese steel

- Wheel Type:Four all-steel wheels with sealed ball bearings

- Safety Features:Sealed ball bearings, safety features

- Application Environment:Heavy-duty industrial, crane systems

- Additional Feature:Fully assembled kit

- Additional Feature:Impact-resistant powder coating

- Additional Feature:Protective gloves included

VEVOR Manual Trolley 2200 lbs Adjustable I-Beam

If you’re seeking a heavy-duty trolley that can handle demanding lifting tasks, the VEVOR Manual Trolley stands out with its impressive 2200-pound capacity and adjustable fit for various I-beams. Its adjustable width from 2.5 to 7 inches, combined with 60 washers, ensures a secure, snug fit on different steel beams. Made from durable alloy steel, it’s built for strength, corrosion resistance, and long-lasting use. Safety features like collision bumpers, anti-drop wire pins, and hex nuts add peace of mind during operation. Quick to install, it’s versatile enough for factories, construction sites, and warehouses, making it a reliable choice for heavy lifting needs.

- Load Capacity:2200 lbs (1 ton)

- Adjustable Width Range:2.5-7 in

- Construction Material:Alloy steel

- Wheel Type:All-steel wheels with sealed bearings

- Safety Features:Locking nut, safety features

- Application Environment:Industrial overhead systems, heavy-duty

- Additional Feature:60 washers included

- Additional Feature:Heavy-duty alloy steel

- Additional Feature:Simple, tool-free adjustment

Factors to Consider When Choosing an Overhead Beam Clamp Trolley

When selecting an overhead beam clamp trolley, I focus on key factors like beam compatibility, load capacity, and durability to guarantee it meets my needs. Safety features and ease of installation are also vital to prevent accidents and save time. Considering these points helps me choose a trolley that’s reliable and suited for my specific setup.

Beam Compatibility Requirements

Choosing the right overhead beam clamp trolley depends heavily on its compatibility with your beam. First, check that the flange width adjustment range matches your beam width, usually from 1.57 to 8.46 inches, for a secure fit. It’s also essential to verify the trolley can accommodate your beam type, whether standard or wide flange I-beams, ensuring proper engagement and safety. I always confirm that the beam’s height and profile allow the trolley’s hooks or clamps to attach securely without interference or slipping. Additionally, I review the maximum load capacity to match your loads and the beam’s structural limits. Ultimately, I verify the trolley’s movement mechanism and locking features are suitable for your beam’s shape and surface, preventing derailment during use.

Load Capacity Considerations

Ensuring the trolley’s load capacity surpasses your maximum expected weight is essential for safety and reliability. I always verify that the trolley can support the total weight of the load plus any lifting equipment like hoists or slings. It’s important to take into account the trolley’s own weight so it doesn’t significantly reduce the maximum load capacity. Matching the trolley’s capacity with the beam’s capacity helps prevent overloading both components during operation. I recommend choosing a trolley with a higher load rating than your current needs to account for future load increases or added safety margins. This approach ensures the trolley operates safely under all circumstances and reduces the risk of equipment failure or accidents. Proper load capacity consideration is key to safe and effective overhead lifting.

Material and Durability

Material selection plays a significant role in determining an overhead beam clamp trolley’s strength and longevity. Using high-quality materials like manganese steel or alloy steel guarantees the trolley can withstand heavy loads and resist wear and corrosion over time. A durable finish, such as powder coating, adds extra protection against rust, impacts, and environmental damage, extending the trolley’s lifespan. The thickness and quality of the steel components directly influence the load-bearing capacity and reliability during long-term use. Heavy-duty features like sealed ball bearings and reinforced joints help the trolley move smoothly and require less maintenance. By prioritizing the right materials and durability features, you ensure your trolley remains safe, efficient, and dependable under repeated heavy-duty conditions.

Safety Features Needed

Have you ever considered how crucial safety features are when selecting an overhead beam clamp trolley? Safety features like anti-loose locking nuts prevent accidental detachment, ensuring the trolley stays secure during operation. Locking mechanisms are essential for keeping the trolley firmly attached to the beam, reducing the risk of falls or slips. Emergency stop switches or safety interlocks give you immediate control to halt movement if necessary, preventing accidents. Side guide rollers and bumpers help maintain stability, minimizing derailments or collisions. Additionally, load capacity indicators and safety ratings confirm the trolley can handle the intended weight safely, avoiding overload hazards. Prioritizing these safety features protects workers and ensures reliable, worry-free operation over the long term.

Ease of Installation

Choosing an overhead beam clamp trolley that’s easy to install can save you time and reduce frustration. Look for models with clearly labeled adjustment mechanisms like bolts or nuts, which make securing the trolley quick and straightforward. An adjustable flange width that matches your beam dimensions simplifies the setup process, preventing the need for extra tools or modifications. Make sure the trolley comes with all necessary hardware, such as brackets or mounting plates, to avoid hunting for parts. User-friendly features like thumb screws or tool-free adjustments can greatly cut down installation time and complexity. Ultimately, select a design that allows for easy alignment and securing without specialized skills or extensive training, ensuring a smooth and hassle-free installation experience.

Frequently Asked Questions

What Safety Features Are Essential in Overhead Beam Clamp Trolleys?

Safety features are vital in overhead beam clamp trolleys. I always look for locking mechanisms that prevent accidental movement, sturdy construction for durability, and secure load capacity indicators. It’s also important to have reliable brakes and safety latches to prevent falls or slips. These features give me peace of mind knowing I can work safely without worrying about equipment failure or accidents.

How Do I Determine the Correct Trolley Capacity for My Application?

To determine the correct trolley capacity, I first assess the weight of the load I’ll be moving, then add a safety margin of about 25-50%. I also consider the trolley’s maximum load rating and make sure it matches or exceeds my needs. It’s vital to account for any dynamic forces during movement. Always consult manufacturer specs and, if unsure, seek expert advice to guarantee safety and efficiency.

Can These Trolleys Be Used on Curved or Irregular Beams?

Yes, many overhead beam clamp trolleys can be used on curved or irregular beams, but it depends on the specific model. I recommend checking the product specifications for compatibility with non-standard beams. Some trolleys are designed with adjustable or flexible wheels that accommodate curves, making them versatile for different beam shapes. Always verify with the manufacturer or supplier to guarantee safe and effective use on irregular surfaces.

What Maintenance Is Required to Ensure Trolley Longevity?

To keep my trolley running smoothly, I make it a point to regularly inspect and clean the wheels and track. Lubricating moving parts prevents rust and wear, which is essential for longevity. I also check for any signs of damage or loose components and address these issues promptly. Staying on top of maintenance is like a well-oiled machine—keeps everything ticking along without a hitch.

Are There Compatibility Issues With Different Beam Sizes and Types?

Yes, compatibility can be an issue if beam sizes or types don’t match the trolley specifications. I always double-check the beam’s dimensions and material before purchasing. For example, some trolleys work only with I-beams or specific widths. If you’re unsure, it’s best to consult the manufacturer’s guidelines or a professional to verify the trolley will fit securely and work safely on your beam.

Conclusion

Choosing the right overhead beam clamp trolley can subtly elevate your lifting experience, ensuring safety and efficiency without drawing undue attention. By considering capacity, adjustability, and build quality, you’ll find a reliable partner for your projects. Remember, the perfect trolley quietly supports your efforts, blending seamlessly into your workflow. With the right choice, you’ll enjoy smoother operations and peace of mind—making your tasks feel less like a challenge and more like a well-orchestrated routine.