To understand chain breakers and rivet spinners, you’ll learn that chain breakers remove or insert pins to adjust chain length, while rivet spinners secure rivets in jewelry making. Both tools have essential components like press pins and rotating chucks to guarantee precise work. Choosing the right tool depends on your project and material, while proper technique and regular maintenance help prevent damage. Keep exploring to master these essential skills and improve your craftsmanship.

Key Takeaways

- Chain breakers remove or install chain pins to disconnect or reconnect links, ensuring chain integrity and smooth operation.

- Rivet spinners securely attach or remove rivets by deforming the rivet tail with controlled, rotating force.

- Selecting the right tool type (manual, hydraulic, specialized) depends on chain size, material, and project scope.

- Proper alignment, steady pressure, and regular maintenance are essential for effective, damage-free chain and rivet work.

- Matching tools to specific materials and following correct techniques extend tool lifespan and ensure professional results.

Understanding the Purpose of Chain Breakers and Rivet Spinners

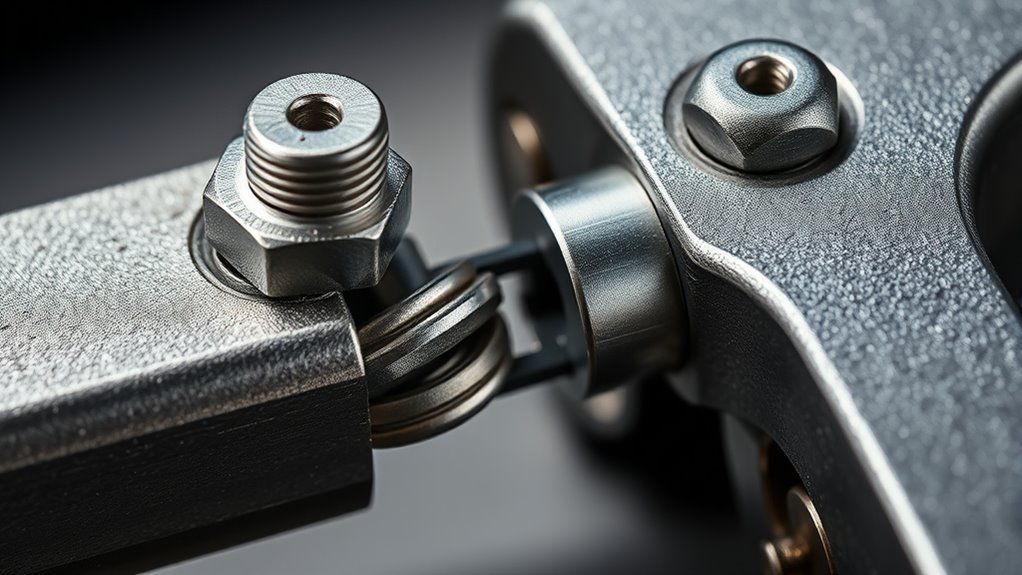

Understanding the purpose of chain breakers and rivet spinners is essential if you’re working with chain assemblies or repairs. Chain breakers are designed to remove or install chain pins, allowing you to disconnect or reconnect chain links easily. This helps you replace worn-out sections or customize chain lengths without damaging the links. Proper tool maintenance ensures their longevity and optimal performance during repairs. Rivet spinners, on the other hand, are used to form or remove rivets, which secure chain links together. They enable you to press rivets in place or drive them out without damaging the chain components. Both tools are vital for maintaining chain integrity and ensuring smooth operation. Additionally, understanding the chain construction can help you select the right tools and techniques for different types of chains. Recognizing the variety of chain styles is important for choosing the appropriate repair method and tools. Being familiar with technological advancements in chain repair tools can further enhance efficiency and precision. By understanding their functions, you can efficiently perform repairs, modifications, or maintenance, saving time and preventing costly mistakes during chain work.

Key Components of Chain Breaker Tools

A chain breaker tool consists of several key components that work together to efficiently remove or install chain pins. First, the press pin is essential—it applies force to push the chain pin out. Without it, the chain stays intact. Second, the body or frame provides stability, guaranteeing precise alignment of the chain and the pin. Third, the replacement or adjusting screw allows you to control the force and position, making pin removal or insertion smooth and safe. Additionally, understanding the essential oils for chain health can promote better maintenance and longevity of your bike chain. Using the correct industry-standard components ensures your tool functions effectively and safely. Proper alignment and material durability are vital to prevent damage during the process. Recognizing the importance of regular maintenance can extend the lifespan of your chain and tools. Understanding these components helps you use the tool effectively:

- The press pin ensures force is directed correctly.

- The body stabilizes your work for accuracy.

- The screw adjusts pressure, preventing damage.

Types of Chain Breakers and Their Uses

You’ll find different types of chain breakers designed for specific tasks, from manual to hydraulic models. Some tools are specialized for particular chains, while others are versatile enough for various sizes. Portable options are great on the go, whereas stationary tools suit workshop setups.

Manual vs. Hydraulic Breakers

Manual and hydraulic chain breakers each serve different needs depending on the scope of work and the environment. Manual tools are ideal for small jobs or tight spaces where power sources are limited. Hydraulic breakers excel in heavy-duty tasks, providing greater force with less effort. When choosing between them, consider:

- The size of the chain and the force needed to break it

- The work environment—tight spaces versus open areas

- The frequency of use—occasional versus continuous work

- Proper technique is essential for effective and safe chain breaking, especially when using manual tools. Additionally, understanding the different types of chain breakers can help select the most suitable tool for your specific needs. Proper maintenance and understanding safety precautions are vital to prevent accidents and ensure longevity of your equipment. Knowing the various chain breaking methods can also influence your choice of equipment and techniques for optimal results.

Manual breakers are portable, simple, and require no power, making them suitable for quick, light tasks. Hydraulic breakers, on the other hand, are more powerful, efficient, and better suited for large, demanding jobs. Your choice depends on your specific project needs.

Specialized vs. Universal Tools

While specialized chain breakers are designed for specific types of chains and materials, universal tools aim to handle a variety of chain sizes and styles with a single device. If you work with different chain types regularly, a universal tool offers convenience and cost savings, eliminating the need for multiple devices. These tools usually have adjustable settings or interchangeable parts to fit various chain widths and link types. However, they might not perform as efficiently on certain heavy-duty or very specialized chains. Specialized tools, on the other hand, are tailored for specific chain styles, providing more precise and easier operation. Choose a specialized tool if you deal mainly with one chain type, but opt for a universal device if your work involves multiple chain styles frequently.

Portable vs. Stationary Models

Portable chain breakers are designed for convenience and mobility, making them ideal for on-the-spot repairs, fieldwork, or situations where taking bulky equipment isn’t practical. They’re compact, lightweight, and easy to carry, allowing you to work anywhere. Stationary models, on the other hand, are larger, heavier, and typically used in workshops or garages where space isn’t an issue. They provide more power, durability, and precision for frequent or heavy-duty tasks. Sound healing science indicates that the right environment and tools can enhance focus and efficiency during work tasks. Consider these points: 1. Portability suits quick fixes and on-site work. 2. Stationary tools excel in high-volume or detailed projects. 3. Your choice depends on how often and where you’ll be working. 4. Selecting the appropriate tools and equipment can improve task efficiency and outcomes. 5. The contrast ratio of your tools can influence the clarity and precision of your work, especially in detailed repairs. Incorporating ergonomic design principles can further reduce fatigue and increase accuracy during prolonged tasks. Additionally, understanding annuity options and their features can help in planning long-term maintenance and upgrades for your equipment. Choosing the right model guarantees efficiency and ease in your chain maintenance tasks.

How Rivet Spinners Function in Jewelry Making

Rivet spinners play an essential role in jewelry making by securely attaching rivets to metal components. You operate the tool by inserting the rivet into the spinner’s chuck, which holds it firmly in place. As you activate the spinner, it uses a rotating motion combined with controlled pressure to flatten and deform the rivet’s tail, creating a secure and clean attachment. The spinning action ensures even distribution of force, preventing damage to delicate metal parts. You can adjust the speed and pressure settings depending on the rivet size and material. This process not only ensures a strong hold but also produces a professional, polished look. Rivet spinners streamline the assembly process, making it easier for you to attach rivets quickly and precisely. Proper technique in operating rivet spinners is crucial to achieve consistent and durable results.

Selecting the Right Tool for Your Project

Choosing the right tool is key to a successful project. You need to match the tool type to the specific task, whether it’s breaking a chain or spinning a rivet. Make sure the tool you select is suitable for the material you’re working with to get the best results.

Choosing the Correct Tool Type

Selecting the right tool for your project is essential to guarantee efficiency and quality. First, identify whether you need to remove or install rivets or chain links, as this determines the tool type. Second, consider the size and strength of the materials involved, ensuring the tool matches these specifications. Third, evaluate your experience level; choosing user-friendly tools reduces mistakes and speeds up the process. For example, a manual rivet spinner works well for small jobs, while power tools are better for larger projects. Picking the correct tool type minimizes damage, saves time, and results in a professional finish. Always match your tool choice to the task at hand, avoiding shortcuts that could compromise the project’s integrity.

Matching Tool to Material

To guarantee your project turns out well, it’s essential to match your tool to the specific material you’re working with. Different metals and materials require different tools to prevent damage and ensure a clean result. For example, softer metals like aluminum need lighter, more precise tools to avoid bending or crushing. Harder materials like steel demand stronger, more durable tools designed to cut or shape without breaking. Using the wrong tool can lead to ruined workpieces, wasted time, and potential safety hazards. Always check the tool’s specifications and recommended uses before starting. If you’re unsure, consult the manufacturer’s instructions or ask an expert. Matching the right tool to your material helps you work efficiently and produces professional-quality results.

Step-by-Step Guide to Using a Chain Breaker

Using a chain breaker properly is essential for removing or shortening a bike chain without causing damage. First, identify the link you want to remove. Next, position the chain in the tool so that the pin lines up with the chain’s rivet. Turn the handle slowly to push the pin out, but don’t force it—patience prevents damage. Finally, after removing or adjusting the chain, reassemble it by aligning the links and carefully reinserting the pin. Remember these key points:

Proper chain breaking prevents damage and ensures smooth reassembly.

- Always check that the chain is secured correctly in the tool.

- Turn the handle gradually to control pin removal.

- Ensure the chain is clean and free of debris for smooth operation.

Following these steps guarantees a clean, damage-free chain break or shorten.

Techniques for Proper Rivet Spinning

Mastering proper rivet spinning is essential for maintaining a strong, reliable chain connection. To do this, apply steady, even pressure as you spin the rivet, ensuring a smooth, uniform head. Keep the rivet aligned with the chain link to prevent wobbling or uneven heads. Use a rivet spinner that fits the rivet size and shape, and work gradually, checking your progress frequently. Proper technique minimizes stress on the rivet and chain, extending their lifespan. Here’s a quick guide to key techniques:

| Technique | Purpose | Tip |

|---|---|---|

| Consistent Pressure | Ensures even rivet heads | Apply steady, controlled force |

| Proper Alignment | Prevents wobbling | Keep rivet centered during spinning |

| Gradual Spinning | Avoids deforming the rivet | Spin in small, controlled motions |

| Check for Security | Ensures a firm hold | Test rivet stability after spinning |

Common Mistakes and How to Avoid Them

Common mistakes during rivet spinning can compromise the strength and durability of your chain. To avoid issues, pay attention to these common errors.

- Over-tightening the rivet: This can cause cracks or weaken the chain. Always apply steady, controlled pressure.

- Uneven rivet formation: Inconsistent spinning leads to weak spots. Ensure the rivet is evenly shaped on all sides.

- Using the wrong tools or size: Picking the incorrect rivet size or tool can result in poor fit and reduced strength. Double-check your tools and materials before starting.

Maintenance and Care for Your Tools

Proper maintenance and care of your tools are essential to guarantee consistent, high-quality rivet spinning. Regularly clean your tools after each use to remove dirt, grease, and debris that can cause corrosion or affect performance. Lubricate moving parts with light machine oil to keep them functioning smoothly, preventing rust and wear. Store your tools in a dry, organized space to avoid damage and corrosion. Check for wear or damage before each use, replacing worn parts immediately to ensure safety and efficiency. Sharpen or replace components as needed to maintain peak performance. Proper care extends the lifespan of your tools and ensures reliable results every time you use them. Dedicate a few minutes to maintenance, and you’ll improve both safety and the quality of your work.

Frequently Asked Questions

Can Chain Breakers Be Used on All Types of Chains?

Not all chain breakers work on every type of chain. You need to check the chain’s material and link design first. Some chain breakers are designed specifically for bike chains, while others suit motorcycle or industrial chains. Using the wrong tool can damage the links or make removal difficult. Always verify the chain breaker’s compatibility with your chain type to guarantee safe, effective removal and prevent damage.

What Safety Precautions Should I Take When Using These Tools?

When using chain tools, you should always wear safety glasses to protect your eyes from flying debris. Make sure the chain is securely clamped to prevent slipping. Keep your fingers clear of the tool’s moving parts, and work in a well-lit area. Follow the manufacturer’s instructions carefully, and don’t force the tool if it’s resisting. Taking these precautions helps prevent injuries and guarantees safe, effective use.

Are There Eco-Friendly or Sustainable Options for Chain Breaking?

You’re wondering if there are eco-friendly or sustainable options for chain breaking. You can look for tools made from recycled or biodegradable materials, which reduce environmental impact. Some brands offer durable, reusable tools that last longer, minimizing waste. Additionally, choose tools that require less energy to operate or are manually powered, avoiding batteries or electricity. By selecting these options, you help promote sustainability while maintaining effective chain-breaking practices.

How Long Do Rivet Spinners Typically Last With Regular Use?

Imagine holding a rivet spinner, its metal smooth and cool against your hand, ready for regular use. Typically, with proper care, it lasts several years — around 3 to 5 — enduring the wear and tear of your projects. Keep it clean, avoid over-tightening, and store it in a dry place. With these habits, your tool remains reliable, helping you craft and repair with ease for many seasons.

Can These Tools Be Used for Repairing Other Jewelry Components?

Yes, you can use rivet spinners and chain breakers for repairing other jewelry components. These tools are versatile and help you remove or set rivets, pins, and small connectors efficiently. With proper handling, you can repair or modify earrings, necklaces, or bracelets. Just make sure to choose the right size and type of tool for the specific task, and work carefully to avoid damaging delicate jewelry pieces.

Conclusion

Now that you know how chain breakers and rivet spinners work, you’re armed with the tools to craft jewelry with confidence. Think of these tools as your trusted companions, guiding your hands through each delicate twist and break, turning raw materials into shining masterpieces. With practice, you’ll transform simple components into intricate art—your creative journey unfolding like a blossoming flower, revealing beauty and craftsmanship at every turn.