Catalytic combustors work by passing exhaust gases over a catalyst, usually made of precious metals like platinum or palladium, which speeds up chemical reactions without being consumed. This process helps break down pollutants such as carbon monoxide, unburned hydrocarbons, and nitrogen oxides into less harmful substances like carbon dioxide, water, and nitrogen. By making combustion more efficient and cleaner, they reduce emissions. Keep exploring to discover how these devices optimize air quality and energy use.

Key Takeaways

- Catalytic combustors use catalysts to speed up combustion reactions, lowering activation energy and enabling cleaner, more efficient fuel burning.

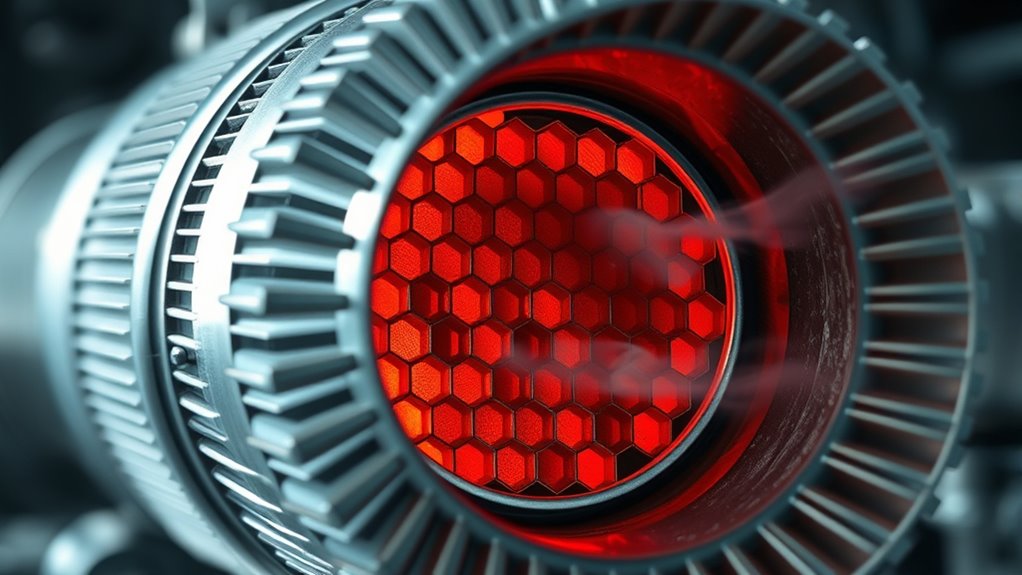

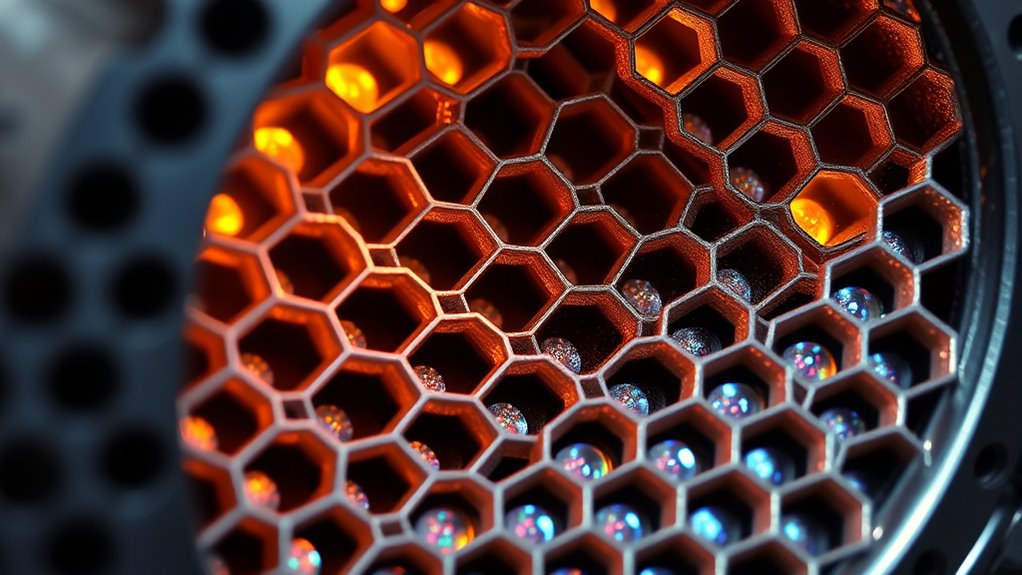

- They contain a coated honeycomb structure that facilitates contact between exhaust gases and catalyst metals like platinum or palladium.

- Catalysts promote conversion of pollutants such as CO, HC, and NOx into less harmful substances like CO₂, N₂, and H₂O.

- By enabling combustion at lower temperatures, catalytic combustors improve stability, reduce emissions, and enhance overall system efficiency.

- Sensors and thermal management systems optimize operation, ensuring maximum pollutant reduction and compliance with environmental standards.

The Role of Catalysts in Combustion Processes

Catalysts play a crucial role in combustion processes by increasing reaction rates without being consumed themselves. When you introduce a catalyst into a combustion system, it offers an alternative pathway with a lower activation energy. This means fuels ignite more easily and burn more completely, reducing emissions and improving efficiency. Understanding catalytic mechanisms helps in designing more effective catalysts for various applications. By facilitating faster chemical reactions, catalysts help maintain stable flames at lower temperatures, preventing issues like excessive soot or unburned fuel. They also enable cleaner combustion by promoting the oxidation of carbon monoxide and unburned hydrocarbons into carbon dioxide and water. Catalyst efficiency is essential for optimizing performance and environmental impact in modern systems. Your use of catalysts ensures the process is more efficient, environmentally friendly, and cost-effective, making them essential components in modern combustion systems. Their ability to accelerate reactions without depleting themselves underpins their importance. Additionally, the integration of essential oils in aromatherapy demonstrates how catalysts can enhance processes by optimizing conditions for desired outcomes. Furthermore, ongoing research into catalyst durability is vital to improve their longevity and performance in various combustion environments. Understanding AI security vulnerabilities is also crucial to safeguarding the development and deployment of these advanced technologies.

Components of a Catalytic Combustor

A catalytic combustor consists of several key components that work together to facilitate efficient and clean combustion. The most important part is the catalyst itself, usually a ceramic or metallic honeycomb structure coated with precious metals like platinum or palladium. This structure provides a large surface area for reactions to occur. The support frame holds everything in place while withstanding high temperatures and thermal expansion. Surrounding the catalyst is the combustion chamber, which directs airflow and fuel mixture over the catalyst. You’ll also find sensors that monitor temperature and emissions, ensuring ideal operation. Additionally, insulation materials are used to protect components and maintain heat within the combustor. Advanced filtration technologies play a crucial role in enhancing overall system performance and environmental compliance. Proper insulation not only improves efficiency but also helps in thermal management by reducing heat loss during operation. Incorporating precious metal coatings can further enhance catalytic activity and durability.

The Chemical Reactions Facilitated by Catalytic Devices

When a catalytic combustor operates, it facilitates chemical reactions that convert harmful pollutants into less harmful substances. You’ll see that nitrogen oxides (NOx) are reduced to nitrogen (N₂) and oxygen (O₂), which are harmless. Carbon monoxide (CO), a toxic gas, reacts with oxygen to produce carbon dioxide (CO₂). Unburned hydrocarbons (HC), which contribute to smog, are broken down into carbon dioxide and water. These reactions occur on the catalyst’s surface, where the metals like platinum or palladium help lower activation energy. The process guarantees that pollutants are transformed efficiently as the exhaust gases pass through. By enabling these chemical reactions, catalytic devices substantially reduce the emission of dangerous substances, making your vehicle’s exhaust cleaner and safer for the environment.

Benefits of Using Catalytic Combustors for Emission Control

Using catalytic combustors offers significant benefits for emission control by dramatically reducing harmful pollutants released into the atmosphere. They efficiently convert dangerous substances like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful gases such as carbon dioxide, water vapor, and nitrogen. This process helps meet strict environmental regulations and improves air quality. Because catalytic combustors operate at lower temperatures than traditional systems, they consume less fuel and generate less heat, increasing energy efficiency. They also produce fewer emissions of incomplete combustion byproducts, reducing health hazards and environmental damage. Additionally, their durability and reliability mean you’ll experience fewer maintenance issues. Incorporating digital literacy in maintenance training can further enhance system performance and troubleshooting. Developing a comprehensive maintenance plan can aid in early detection of potential issues, ensuring optimal operation. Understanding self-watering plant pots can illustrate the importance of proper system management for longevity and efficiency. Proper system monitoring can also detect inefficiencies early and optimize combustor performance, extending system life. Overall, using catalytic combustors not only helps protect the environment but also enhances your system’s performance and longevity.

Applications and Future Developments in Catalytic Combustion Technology

Advancements in catalytic combustion technology are expanding its applications across diverse industries, driven by the need for cleaner and more efficient energy solutions. You’ll find catalytic combustors now used in power plants, industrial processes, and even in aerospace to reduce emissions and improve fuel efficiency. As research progresses, new catalysts and materials emerge, allowing for higher temperatures, lower costs, and longer lifespans. Future developments aim to integrate catalytic combustion with renewable energy sources, such as biofuels and waste-to-energy systems. You might also see innovations in micro-catalytic systems for portable and distributed power generation. These advancements will make catalytic combustion more versatile, sustainable, and accessible, helping industries meet stricter environmental standards while reducing their carbon footprint. Catalytic combustors are also being optimized to operate efficiently with alternative fuels, further enhancing their role in sustainable energy solutions. Incorporating creative problem-solving approaches in research accelerates the discovery of innovative catalysts and materials for next-generation systems.

Frequently Asked Questions

How Do Catalysts Withstand High Temperatures in Combustion Engines?

You might wonder how catalysts survive extreme heat in engines. They’re made from heat-resistant materials like platinum, palladium, or rhodium, which can withstand high temperatures without melting or degrading. These metals are often supported on sturdy ceramic or metallic substrates that disperse heat evenly. This design helps the catalyst maintain its effectiveness, allowing it to break down pollutants efficiently even under intense combustion conditions.

What Materials Are Most Commonly Used in Catalytic Combustor Construction?

You want to know what materials are most common in catalytic combustor construction. Typically, you’ll find precious metals like platinum, palladium, and rhodium acting as catalysts because they speed up reactions without degrading. These metals are supported on ceramic substrates made from materials like cordierite, which withstand high temperatures and provide durability. You might also see stainless steel or other heat-resistant alloys used for the outer shell, ensuring longevity and performance.

How Is Catalyst Deactivation Prevented or Reversed Over Time?

Imagine a garden where plants sometimes wither; you’d water and prune to revive them. Similarly, you prevent catalyst deactivation by regular maintenance, like cleaning and regeneration, removing poisons and buildup. Sometimes, you can even restore activity through special treatments that rejuvenate the catalyst’s surface. This proactive approach keeps your catalytic combustor efficient, ensuring it continues to convert harmful emissions into safer gases effectively over time.

Are Catalytic Combustors Effective With Alternative Fuels Like Biofuels?

You might wonder if catalytic combustors work well with biofuels. The good news is, they’re generally effective because biofuels contain similar compounds to traditional fuels, allowing the catalyst to facilitate combustion efficiently. However, some biofuels may introduce impurities or different chemical compositions that could affect performance or lead to quicker catalyst deactivation. Regular maintenance and proper fuel selection can help guarantee ideal operation with alternative fuels.

What Are the Environmental Impacts of Catalyst Disposal After Use?

You’re concerned about the environmental impacts of catalyst disposal after use. When you discard used catalysts, hazardous metals like platinum, palladium, and rhodium can leach into soil and water, contaminating ecosystems. Proper recycling and disposal methods help prevent pollution, but if not managed correctly, they pose risks to wildlife and human health. Being aware of and supporting responsible disposal practices guarantees you minimize negative environmental effects from catalyst waste.

Conclusion

Understanding how catalytic combustors work is like revealing a secret to cleaner air. By using catalysts, you can turn harmful emissions into safer gases more efficiently, just as a skilled chef transforms raw ingredients into a delicious meal. Embracing this technology means you’re helping reduce pollution and protect the environment. As advancements continue, these devices become more essential—like a lighthouse guiding us toward a greener, healthier future.