To reduce vibrations effectively, you can use passive devices like mounts, isolators, and tuned mass dampers to absorb unwanted energy. Structural upgrades, such as adding stiffeners or choosing damping materials, also help. Advanced options include base isolators and active control systems that adapt to changing forces. Combining these techniques offers a thorough solution. If you want to explore these options in detail, you’ll find helpful insights ahead.

Key Takeaways

- Implement passive damping devices like rubber mounts, tuned mass dampers, or elastomeric supports to absorb vibrational energy effectively.

- Reinforce structures with stiffeners, bracing, or material upgrades such as composites and elastomers to enhance vibration resistance.

- Use vibration isolators and mounts tailored to equipment weight and environment to reduce transmission and noise.

- Apply base isolation systems and tuned mass dampers to mitigate seismic and wind-induced vibrations in buildings.

- Incorporate active vibration control systems with sensors and actuators for real-time vibration monitoring and dynamic mitigation.

Passive Vibration Damping Devices

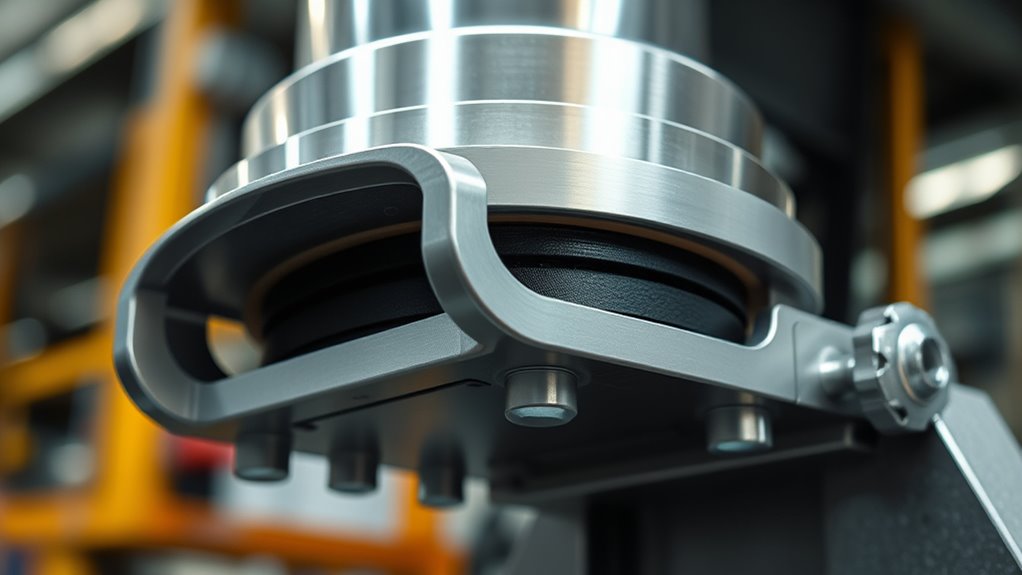

Passive vibration damping devices are essential tools for reducing unwanted vibrations without requiring external power sources. They work by absorbing or dissipating vibrational energy directly through their materials and design. When vibrations occur, these devices convert kinetic energy into heat or deform elastically, preventing the vibrations from transferring to sensitive equipment or structures. Common types include rubber mounts, damping pads, and tuned mass dampers. You can easily install them on machinery bases, supporting structures, or equipment mounts. Passive dampers are reliable, maintenance-free, and cost-effective, making them ideal for many industrial and commercial applications. They provide consistent performance without the complexity of active control systems, ensuring that vibrations are minimized efficiently and quietly. Utilize digital platforms to identify suitable options and optimize their placement for maximum vibration reduction. Additionally, choosing appropriate material composition can significantly enhance the effectiveness of these devices in specific environments. Incorporating proper installation techniques can further improve their performance and lifespan. Understanding wave characteristics can also help in selecting the most effective damping solutions for different vibration scenarios.

Vibration Isolators and Mounts

Vibration isolators and mounts come in various types designed to reduce noise and movement transfer effectively. Choosing the right one depends on your equipment’s weight, operating conditions, and desired isolation level. Proper mounting and installation are vital to guarantee these devices perform at their best and last longer. Selecting a mount that is suitable for the specific dog bed size can help ensure optimal support and stability.

Types of Vibration Isolators

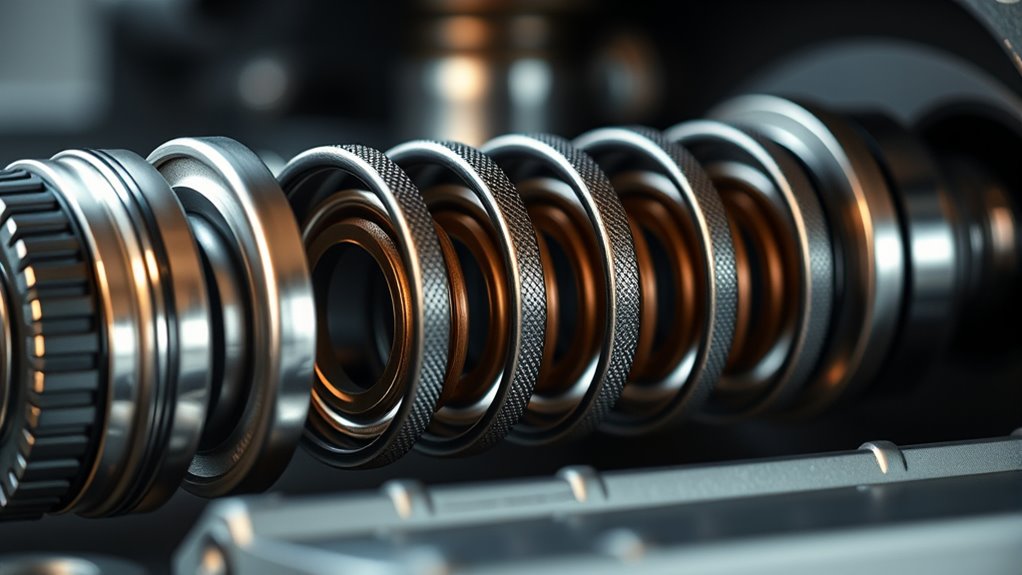

When selecting vibration isolators and mounts, understanding the different types available is essential for effectively minimizing transmission of vibrations. There are several common types, each suited to specific applications. Elastomeric mounts, made from rubber or similar materials, absorb vibrations through their flexibility and damping properties. Coil springs provide support for heavier loads and are useful where high displacement is needed. Air mounts utilize compressed air to isolate vibrations, offering adjustable damping. Torsional isolators reduce rotational vibrations and are ideal for machinery with angular movement. Each type offers unique benefits and limitations, so your choice depends on load weight, vibration frequency, and installation conditions. Proper installation procedures are vital to ensure optimal performance and longevity of the vibration isolation system. Understanding vibration frequency and how it impacts isolation effectiveness can further optimize your setup, especially when considering dynamic loads that can vary during operation. Additionally, considering environmental conditions where the isolators are used can also influence the selection process, ensuring durability and consistent performance over time. Recognizing load weight is crucial for selecting the appropriate isolator type to prevent failure or inefficiency.

Mounting and Installation Tips

Choosing the right mounting and installation methods for vibration isolators guarantees ideal performance and longevity. First, ensure the isolator is properly sized for your equipment’s weight and operational frequency. Mount it on a solid, level surface to prevent uneven stress and shifting. Always follow the manufacturer’s instructions for installation, paying attention to correct orientation and secure fastening. Avoid overtightening mounts, as this can reduce vibration absorption. Use appropriate hardware, like isolator brackets or vibration pads, to minimize transfer. Maintain even spacing and avoid placing isolators near extreme heat or corrosive environments. Regularly inspect your mounts for signs of wear or damage, and replace them as needed. Proper mounting ensures optimal vibration control, reduces noise, and extends the life of your equipment. Additionally, understanding the importance of dynamic contrast ratios can help you select projectors that maintain consistent image quality during different scenes. Incorporating somatic awareness into your installation process can also help identify subtle vibrations that might affect sensitive equipment. Being attentive to sound vibrations and their impact can further enhance equipment stability and performance. Recognizing the influence of projector bulb wear can also help in scheduling timely maintenance to prevent image quality issues.

Tuned Mass Dampers

Have you ever wondered how engineers protect structures from excessive vibrations caused by wind or earthquakes? Tuned mass dampers (TMDs) are a common solution. They consist of a large mass mounted near the top of a building, connected to the structure via springs and dampers. When vibrations occur, the TMD moves out of phase with the building, counteracting oscillations and reducing sway. Proper tuning is essential; the damper’s natural frequency must match the building’s dominant vibration mode for maximum effectiveness. Here’s a quick comparison:

| Aspect | Details |

|---|---|

| Purpose | Reduce sway during dynamic loads |

| Key Component | Large mass with springs and dampers |

| Tuning Requirement | Matches structure’s vibration frequency |

| Effectiveness | Mitigates wind, seismic vibrations |

| Maintenance | Regular checks for ideal operation |

This simple yet powerful device enhances stability and comfort in tall structures. Regular maintenance ensures continued optimal performance and longevity of the damper system. To achieve the best results, engineers often incorporate vibration reduction techniques such as these dampers into their structural designs. Understanding structural dynamics helps in designing more effective vibration mitigation strategies.

Base Isolation Systems

Base isolation systems serve as a proactive approach to safeguarding structures against seismic forces. They work by placing flexible bearings or isolators between a building’s foundation and superstructure, allowing the building to move independently during an earthquake. This minimizes the transfer of seismic energy, reducing vibrations and potential damage. You’ll find these systems typically involve elastomeric bearings or sliding devices that absorb and dissipate seismic shocks. By isolating the structure, you improve its resilience, ensuring occupants’ safety and preserving the building’s integrity. Installation requires careful engineering to match the building’s weight, height, and seismic risk. Although they don’t prevent ground motion, base isolation systems considerably lessen the impact of earthquakes, making them a crucial part of modern seismic-resistant design.

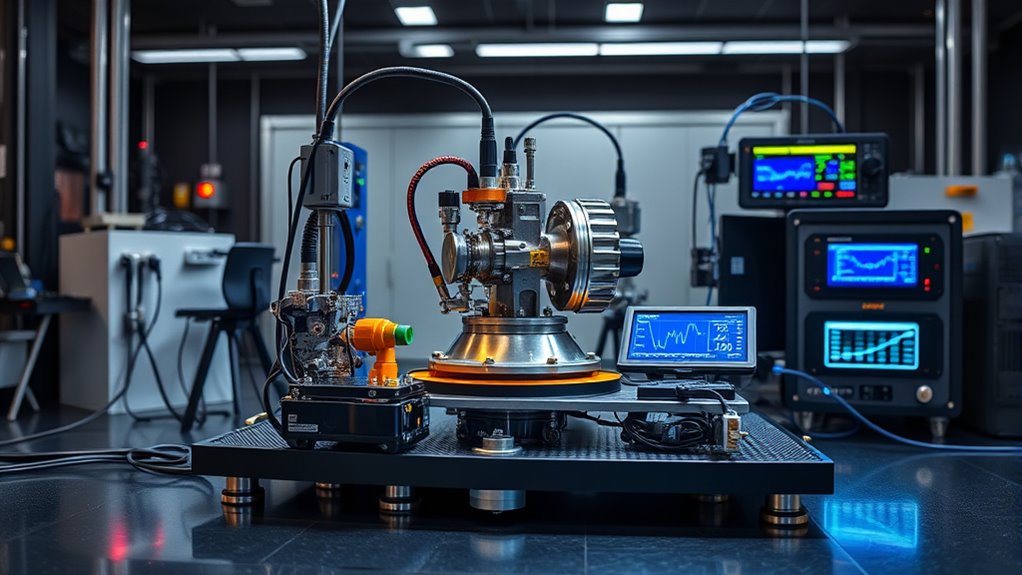

Active Vibration Control Strategies

Active vibration control strategies employ real-time systems that detect and counteract building movements during seismic events. You install sensors throughout the structure to monitor vibrations continuously. When these sensors identify excessive motion, the control system processes the data instantly. It then signals actuators—like hydraulic or electromagnetic devices—to generate counterforces that oppose the detected vibrations. This dynamic response reduces the amplitude of oscillations, protecting the building from damage. These strategies are highly adaptable, adjusting in real-time to changing seismic conditions. They are particularly effective for tall or critical structures where traditional methods may fall short. By actively managing vibrations as they occur, you enhance safety, minimize structural stress, and improve overall resilience during earthquakes.

Vibration Absorbers and Tuned Filters

Vibration absorbers and tuned filters provide a passive approach to mitigating structural vibrations by targeting specific frequencies. You install these devices directly onto the structure or machinery to reduce resonance effects. Vibration absorbers typically consist of mass-spring systems that absorb energy at a particular frequency, preventing it from spreading throughout the structure. Tuned filters, on the other hand, are designed to block or attenuate vibrations within certain frequency ranges, often using damping materials or resonant elements. You can tune these systems precisely to match the problematic frequency, making them highly effective for predictable vibrations. Since they work without active control, they require minimal maintenance and power, offering a reliable, low-cost solution for vibration mitigation across various applications.

Structural Modifications and Design Improvements

You can reduce vibrations by reinforcing and stiffening key structural components, making them more resistant to movement. Selecting appropriate materials also plays a vital role in enhancing a structure’s natural frequency and damping capacity. These design improvements help create a more robust structure that minimizes vibration impacts effectively.

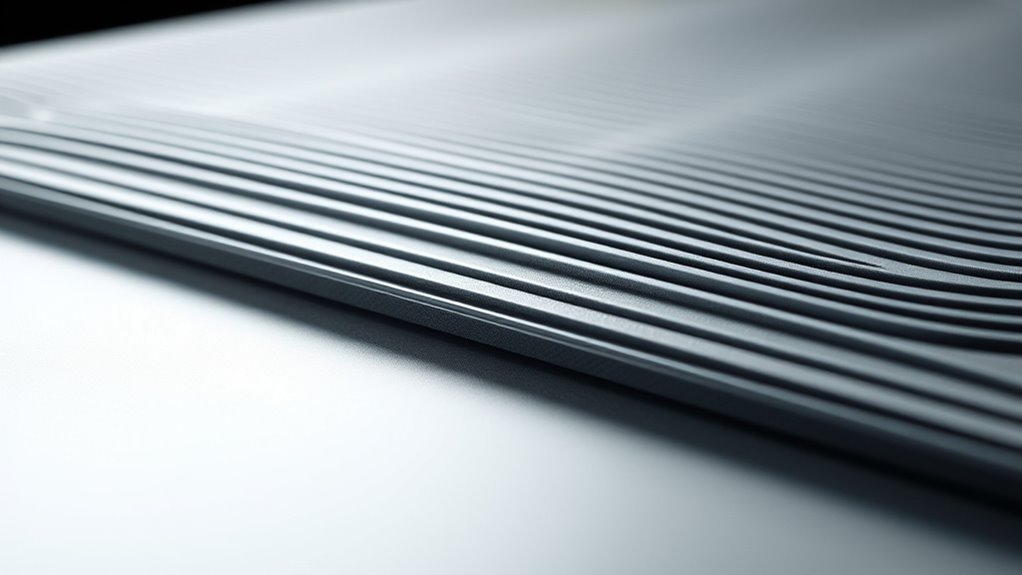

Reinforcement and Stiffening

Reinforcing and stiffening structures through design modifications can substantially reduce vibrations by increasing their ability to resist dynamic forces. You can achieve this by adding bracing, cross-members, or stiffeners to key areas, which distribute stresses more evenly. Increasing the thickness of structural elements or using continuous supports also enhances rigidity. When designing, consider integrating additional supports at critical points where vibrations tend to concentrate. You might also modify the geometry to eliminate weak spots or resonance-prone features. These adjustments help prevent excessive oscillations and improve overall stability. Keep in mind, effective reinforcement requires understanding the dynamic loads involved. Properly stiffened structures respond better to vibrations, reducing the risk of fatigue and structural failure. Focus on strategic modifications that enhance stiffness without unnecessary weight increases.

Material Selection Strategies

Selecting appropriate materials is essential for optimizing structural performance and minimizing vibrations. You should consider materials with high damping capacity to absorb vibrational energy effectively. Lightweight materials, such as composites or aluminum, can reduce the overall mass, lowering the amplitude of vibrations. Additionally, choosing materials with favorable stiffness-to-weight ratios helps prevent excessive deflections. It’s important to evaluate a material’s fatigue resistance and durability, especially for structures subjected to repeated loads. Incorporating materials with inherent vibration-dampening properties, like rubber or specialized polymers, can enhance stability. Remember, the right material selection not only improves vibration control but also extends the lifespan of your structure. By paying close attention to these factors, you can design safer, more resilient systems that perform reliably under dynamic conditions.

Advanced Materials for Vibration Reduction

Advanced materials play a crucial role in enhancing vibration reduction techniques by offering innovative solutions that outperform traditional options. These materials can absorb, dampen, or redirect vibrational energy more effectively, leading to quieter and more stable structures. For example, composites like carbon fiber and polymer-based elastomers provide superior damping properties. You can incorporate these materials into machinery, buildings, or vehicles for improved performance. Here’s a quick comparison:

| Material Type | Vibration Reduction Benefits |

|---|---|

| Viscoelastic Polymers | Excellent energy dissipation, adaptable |

| Metal Matrix Composites | High strength with damping capabilities |

| Nano-engineered Materials | Lightweight, customizable damping |

Choosing advanced materials allows you to optimize vibration control, reducing noise, fatigue, and damage.

Frequently Asked Questions

How Do Environmental Factors Influence Vibration Reduction Effectiveness?

Environmental factors greatly impact how well vibration reduction methods work. When you consider factors like temperature, humidity, and surrounding structures, you realize they can either amplify or dampen vibrations. For example, high humidity might cause equipment to corrode, reducing effectiveness, while nearby heavy machinery can introduce additional vibrations. By understanding and controlling these environmental influences, you can optimize your vibration reduction strategies for better results.

What Are the Cost Considerations for Different Vibration Control Methods?

Did you know that implementing active vibration control can cost up to 50% more than passive methods? When considering different vibration control methods, you need to weigh initial expenses against long-term savings. Passive techniques like isolators are cheaper upfront but less adaptable, while active systems offer precision at higher costs. Your decision depends on balancing budget constraints with the need for effectiveness and flexibility in your specific application.

Can Vibration Reduction Techniques Be Integrated Into Existing Structures?

You can integrate vibration reduction techniques into existing structures, but it depends on the design and current condition. Often, retrofitting involves adding damping devices, isolators, or tuned mass dampers, which can be installed without major renovations. You’ll need to assess the structure’s integrity and consult engineers to guarantee compatibility and effectiveness. With proper planning, these modifications can markedly improve stability without extensive rebuilding.

How Do Maintenance Requirements Vary Among Vibration Mitigation Systems?

Think of maintenance requirements as the gears in a well-oiled machine—each system needs different attention. You’ll find that active mitigation systems often demand regular calibration and sensor checks, while passive ones require periodic inspections for wear and tear. Adaptive systems might need software updates and component replacements. Staying proactive guarantees your vibration mitigation runs smoothly, just like tuning an instrument ensures perfect harmony.

What Are the Latest Innovations in Vibration Reduction Technology?

You’re curious about the latest innovations in vibration reduction technology. Recently, advancements include smart systems that adapt in real-time to changing conditions, using sensors and AI to optimize performance. You’ll also find new materials like viscoelastic composites that absorb vibrations more effectively, and active control systems that counteract vibrations dynamically. These innovations make vibration mitigation more efficient, reliable, and easier to integrate into existing structures and machinery.

Conclusion

Think of vibration reduction like tuning a musical instrument—you want every string to resonate perfectly without unwanted noise. By combining passive devices like isolators with active control strategies, you can create a system that dampens vibrations effectively. Just like a well-tuned guitar, your structure can perform smoothly and reliably. Embracing these techniques turns potential chaos into harmony, ensuring safety and longevity—making your engineering masterpiece sing instead of squeal.