Understanding chainsaw sharpening angles is key to cutting safely and efficiently. Proper angles ensure smooth cuts, reduce wear, and prevent kickbacks. You’ll want to learn about tooth profiles, typical angles (usually around 25° to 35°), and how to measure and set them correctly using guides. Maintaining consistent angles and tension keeps your chain in top shape and extends its lifespan. Keep exploring to discover how to master these techniques and keep your chainsaw performing at its best.

Key Takeaways

- Proper sharpening angles ensure optimal cutting efficiency and safety by reducing kickback and uneven cuts.

- Using a file guide helps maintain consistent angles, typically ranging from 25° to 35° depending on the wood type.

- Correct tooth profile and angle preserve chain tension, extend chain life, and improve performance.

- Regularly checking and adjusting the depth gauges and chain tension enhances safety and cutting precision.

- Consistent maintenance and proper tools preserve angle accuracy, prolong chain lifespan, and ensure safe operation.

Understanding the Importance of Sharpening Angles

Understanding the importance of sharpening angles is essential because the angle directly affects your chainsaw’s cutting efficiency and safety. When you maintain proper angles, your chainsaw slices smoothly, reducing strain and preventing accidents. Using the correct sharpening tools, like a round file or a specialized grinder, ensures you keep the right angle consistently. Always follow safety precautions—wear gloves and eye protection—while sharpening to avoid injuries. Properly sharpened chains not only cut more effectively but also last longer, saving you money and effort. Neglecting the correct angle can lead to uneven cuts, increased kickback risk, and damage to the chain. By paying attention to sharpening angles, you improve safety and maximize your chainsaw’s performance. Additionally, understanding projector contrast ratios can help you achieve sharper images and better visual clarity during your woodworking projects. Maintaining proper sharpening angles also reduces the frequency of sharpening needed, extending the lifespan of your chainsaw chain. Recognizing the correct angles can also prevent premature chain wear and reduce the need for frequent replacements. Proper angle maintenance aligns with rustic decor themes, emphasizing the importance of attention to detail for optimal results. Moreover, paying attention to state tax implications can help optimize your financial planning during retirement.

The Anatomy of a Chainsaw Chain and Its Angles

Understanding the parts of your chainsaw chain helps you sharpen it effectively. You’ll want to pay attention to the tooth shape, the filing angles, and how the depth gauges are adjusted. Mastering these details ensures your chain cuts smoothly and safely. Proper storage of your chainsaw and its components can also help maintain optimal performance over time, similar to how proper storage of essential oils preserves their potency. Regularly inspecting for damage or wear can prevent accidents and prolong the life of your chain. Maintaining a regular maintenance routine is crucial for consistent performance and safety. Keeping track of your maintenance routines can further enhance safety and efficiency. Incorporating proper eye protection during sharpening procedures can also enhance safety and precision.

Tooth Profile and Shape

The tooth profile and shape are vital for effective chainsaw cutting performance, as they determine how the chain interacts with wood. A properly shaped tooth ensures efficient cutting and reduces strain on the engine. The profile influences how the chain maintains tension and stays aligned on the bar, preventing issues like slack or uneven cuts. If the tooth shape is dull or damaged, cutting becomes slower and rougher. Additionally, maintaining correct bar alignment is important, as misalignment can distort the tooth’s profile, affecting its shape and performance. Regularly inspecting the tooth profile helps you identify wear early, making sure the chain remains sharp and effective. Remember, a well-shaped tooth paired with proper chain tension and bar alignment guarantees smoother, safer, and more efficient cuts.

Filing and Sharpening Angles

Proper filing and sharpening angles directly impact how well your chainsaw cuts. When using sharpening tools, always prioritize safety precautions to avoid injuries. The correct angle guarantees efficient cutting and prolongs chain life. Typically, the top plate angle ranges from 25° to 35°, influencing how aggressively your chain bites into wood. To visualize, think of this table:

| Tooth Type | Typical Angle | Purpose |

|---|---|---|

| Cutting tooth | 25°–35° | Fast, aggressive cuts |

| Raker (depth gauge) | 5°–10° | Controls depth of cut |

| Side plate | 25°–35° | Guides the cut and balances chain |

Regularly check these angles and use proper sharpening tools to maintain them. Correct angles optimize performance and safety.

Depth Gauges and Settings

Depth gauges, also known as rakers, determine how deep each cutting tooth bites into wood, making them a vital part of your chainsaw chain’s performance. Proper setting guarantees efficient cuts and reduces strain on the engine. Before adjusting, always wear safety gear to protect yourself. Use sharpening tools designed for depth gauges to achieve accurate measurements. Here’s what to keep in mind: 1. Check the current height of the gauges relative to the cutting teeth. 2. File down the gauges with a safe, precise tool until they sit just above the cutting edge. 3. Regularly inspect and adjust to maintain ideal depth, especially after sharpening the teeth. Additionally, maintaining the correct chain tension ensures the chain moves smoothly through wood and prevents unnecessary wear. Keeping these settings correct improves safety and cutting efficiency, making your sharpening routine more effective.

Common Types of Sharpening Angles and Their Uses

Choosing the right sharpening angle is essential for optimizing your chainsaw’s cutting performance. Different saw blade compatibility requires specific angles to ensure efficient cutting and longevity. For example, a 30-degree angle is common for general-purpose cutting, providing a balance between durability and sharpness. If you’re working with softer woods, a more aggressive 25-degree angle might be suitable, while harder woods benefit from a shallower 35-degree angle. When selecting your sharpening tools, consider the types of angles they can achieve, as this impacts your ability to maintain the correct edge. Using the appropriate angle guarantees your chainsaw cuts smoothly and reduces wear on the chain. Understanding the common types of sharpening angles helps you choose the right approach for your tasks and tools. Proper angle maintenance is crucial for extending the lifespan of your chainsaw, and being aware of angle consistency ensures optimal performance over time. Additionally, consistent sharpening techniques contribute significantly to maintaining the ideal edge and preventing uneven wear.

How to Measure and Set the Correct Angles

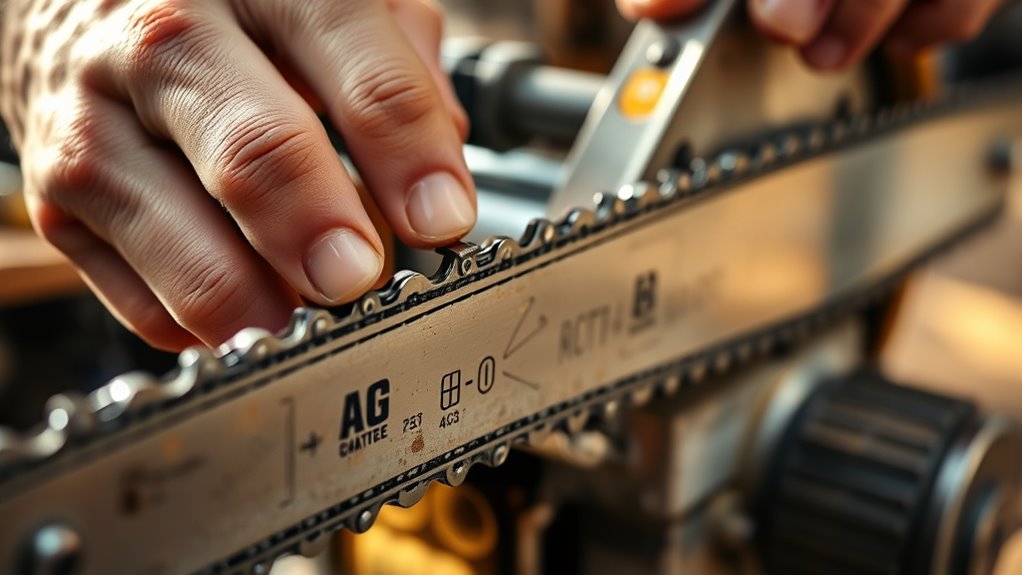

Measuring and setting the correct sharpening angles on your chainsaw blade is essential for peak performance, and doing so accurately guarantees your chain cuts efficiently and lasts longer. To do this effectively: 1. Use a sharpening guide or angle gauge to measure the existing angle, ensuring proper alignment. 2. Set your file or grinder to match the recommended angle for your chain type, keeping lubrication techniques in mind for smooth operation. 3. Always follow safety precautions—wear protective gear and secure the chain—before adjusting or sharpening to prevent accidents. 4. Maintaining the proper sharpening angles can significantly extend the lifespan of your chain and improve cutting performance. Proper angle setting helps maintain ideal cutting efficiency and reduces wear. Regularly checking angles ensures consistent sharpness, while correct blade maintenance techniques can also contribute to longer-lasting and more efficient cuts. Incorporating proper lubrication methods ensures the chain remains cool and reduces unnecessary wear. Properly aligning the chain with the correct sharpening angles can also help prevent uneven wear and tear. Keep safety precautions in mind at all times to avoid injuries during the process.

Step-by-Step Guide to Sharpening Your Chainsaw Properly

Sharpening your chainsaw correctly starts with preparing the tools and setting the right angle. First, wear your safety gear—gloves, goggles, and a face shield—to protect yourself. Gather a round file, a file guide, and a flat file if needed. Before you begin, review your maintenance schedule to verify the chain isn’t worn out. Secure the chainsaw firmly on a stable surface. Start by filing the cutting teeth, maintaining the proper angle you’ve already set. Keep the file level and use smooth, consistent strokes. Sharpen each tooth evenly, then check for uniformity. Proper blade maintenance ensures optimal cutting performance and safety. Regularly inspect your tools and follow this step-by-step process for safe, effective chainsaw sharpening. Additionally, understanding how to address virtual affairs and digital infidelity can be crucial for maintaining trust in personal relationships, especially in today’s digital age.

Tips for Maintaining Optimal Angles During Regular Use

To maintain ideal angles during regular use, it’s essential to pay close attention to how the chainsaw interacts with the wood. Proper chain tension ensures the chain cuts smoothly and maintains the correct angle. Regular bar maintenance, like cleaning and inspecting for wear, helps keep the chain aligned and sharp. Here are three tips:

Maintaining proper chain tension and regular bar maintenance ensures optimal cutting angles and safety.

- Check and adjust chain tension frequently, ensuring it’s snug but still able to move freely.

- Keep the bar clean and lubricated to prevent debris buildup that can affect cutting angles.

- Inspect the chain and bar for wear and replace parts as needed to preserve the best angle and performance.

- Staying informed about the local laws can help ensure your maintenance practices comply with safety regulations.

- Incorporating proper sharpening techniques can significantly improve your chainsaw’s ability to maintain accurate angles and efficient cuts.

Consistent attention to chain tension and bar maintenance keeps your chainsaw cutting at the right angles, reducing fatigue and improving safety.

Frequently Asked Questions

How Often Should I Re-Sharpen My Chainsaw Chain for Optimal Performance?

You should re-sharpen your chainsaw chain regularly to maintain ideal performance. A good maintenance schedule involves checking the chain every few hours of use or after cutting through hard materials. Typically, sharpening frequency depends on your workload, but aim to inspect and sharpen whenever you notice decreased cutting efficiency or increased effort. Consistent maintenance keeps your chainsaw running smoothly, extends chain life, and guarantees safe, effective cutting every time you use it.

Can Incorrect Angles Cause More Wear on My Chainsaw Chain?

Imagine trying to cut through wood with a dull knife; it strains more and wears out faster. Incorrect angles on your chainsaw chain cause similar issues, leading to uneven wear and faster dulling. Poor chain tension and inadequate chain lubrication exacerbate this, increasing wear. When your angles are right, the chain moves smoothly, reducing stress and extending its lifespan. So, always check your angles and maintain proper tension and lubrication.

What Tools Are Best for Maintaining Consistent Sharpening Angles?

To keep your chainsaw chain sharp and consistent, you should use diamond files and angle gauges. Diamond files are excellent for precise sharpening, while angle gauges help you maintain the correct sharpening angle every time. With these tools, you can easily set and verify angles, reducing uneven wear and extending your chain’s life. Regular use of diamond files and angle gauges ensures your chainsaw performs at its best and safely.

Do Different Wood Types Require Specific Sharpening Angles?

When wondering if different wood types demand specific sharpening angles, think about density and cutting precision. Denser woods require a sharper, more precise angle to pierce through tough fibers, while softer woods benefit from a slightly wider angle to prevent dulling. You’ll want to adjust your approach based on these factors, ensuring your chainsaw cuts cleanly and efficiently, transforming tough tasks into simple swipes with the right sharpening strategy.

How Do Environmental Factors Affect Chain Sharpening and Angle Maintenance?

Environmental factors, like humidity effects and temperature influence, markedly impact chain sharpening and angle maintenance. High humidity can cause rust, dulling your chain faster, while low humidity helps preserve sharpness. Temperature fluctuations can expand or contract metal, affecting the angle precision. You should regularly check your chain, especially in extreme weather, and adjust or sharpen as needed to keep it cutting efficiently and safely.

Conclusion

Now that you’ve mastered the art of chainsaw angles, imagine your saw slicing through wood like a hot knife through butter—no more battling stubborn knots or ragged cuts. With the right angles, you’ll be the lumberjack hero, wielding a finely tuned beast that laughs in the face of timber. So sharpen wisely, maintain those angles, and remember: a dull saw is just a fancy paperweight. Happy cutting!