If you’re experiencing low pump pressure, start by inspecting for blockages, leaks, and worn components like seals and impellers. Check for air leaks or loose fittings that could disrupt fluid flow. Regular maintenance, including cleaning filters and tightening connections, can prevent these issues. Monitoring pressure gauges and replacing damaged parts promptly can restore peak performance. Keep going for more tips to help you troubleshoot and fix low pump pressure effectively.

Key Takeaways

- Check for leaks, blockages, or clogs in hoses, fittings, and filters to ensure unobstructed flow.

- Inspect and replace worn or damaged seals, valves, and impellers causing pressure drops.

- Verify all connections are tight and free of air leaks that disrupt system pressure.

- Regularly calibrate pressure gauges and sensors for accurate readings.

- Perform routine maintenance, including cleaning filters and lubricating components, to prevent pressure issues.

Identifying Common Causes of Low Pump Pressure

Low pump pressure can often be traced back to several common issues. One key factor is reduced pump efficiency, which can result from wear, clogging, or misalignment. These problems disrupt fluid dynamics, causing flow restrictions that lower pressure. You might notice leaks or blockages in hoses and fittings that hinder smooth fluid movement. Air leaks can also compromise pressure, as they interfere with the pump’s ability to maintain a proper seal. Additionally, incorrect installation or incompatible system components can negatively impact fluid flow, diminishing pump performance. Understanding how fluid dynamics influence pressure helps you better identify where inefficiencies occur. Recognizing these common causes helps you target repairs effectively, restoring ideal pump operation and maintaining consistent pressure levels.

Inspecting and Maintaining Your Pump System

Regular inspection and maintenance are essential to keep your pump system operating efficiently. Check pump lubrication regularly to prevent wear and overheating, ensuring smooth operation. Maintain seal integrity by inspecting seals for leaks or damage; compromised seals can cause pressure loss. Keep an eye on components that may need tightening or cleaning to avoid unnecessary strain. Additionally, monitoring for expert advice can help identify issues early and prolong the lifespan of your pump.

Troubleshooting Pressure Drop in Pump Components

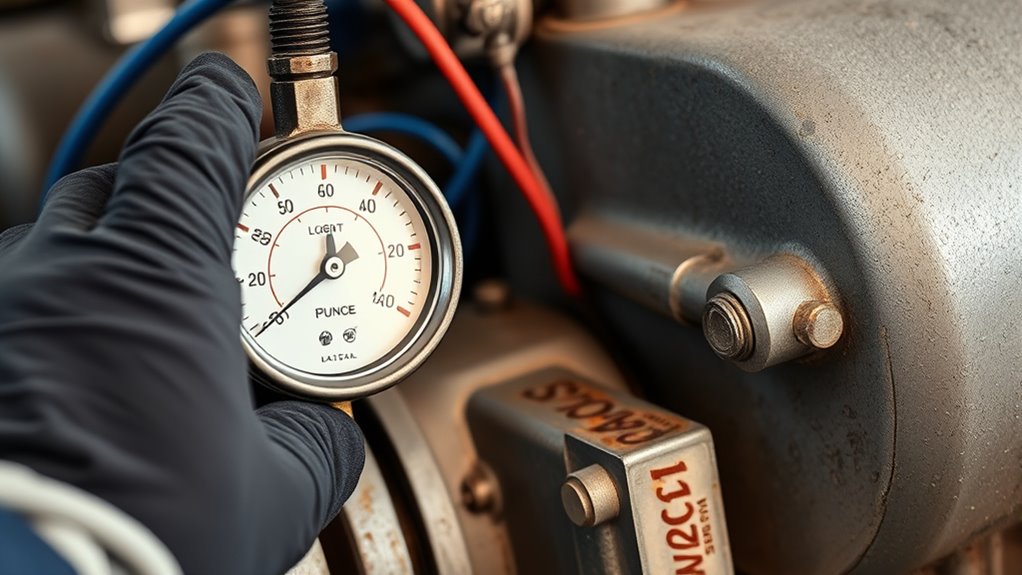

When you notice a sudden pressure drop in your pump, it’s essential to identify the underlying cause quickly to prevent system damage. First, check the pressure gauge calibration; an inaccurate gauge can mislead you about actual pressure levels. If the gauge is correctly calibrated, inspect pump components like seals, valves, and impellers for wear or damage. Worn or faulty parts often cause pressure loss, requiring pump component replacement. Ensure all connections are tight and free of leaks. Regularly verify the pressure gauge’s accuracy to avoid false readings. If you find damaged parts, replace them promptly to restore proper pressure and system performance. Addressing these issues swiftly prevents further damage and keeps your pump running efficiently. Additionally, understanding the pump’s internal mechanisms can help diagnose issues more effectively.

Addressing Blockages and Air Leaks

Blockages and air leaks are common culprits behind pressure issues in your pump system. When a blockage occurs, you’ll notice increased pump vibration as the motor struggles to move fluid through restricted lines. Check your pressure gauge; a sudden drop or inconsistent readings often indicate a blockage. Air leaks, on the other hand, cause pressure loss and can lead to erratic pump operation. Inspect fittings, seals, and hoses for cracks or loose connections. Even small leaks can considerably reduce pressure, so tighten or replace faulty parts. Regularly monitoring your pressure gauge helps identify these problems early. Clearing blockages and sealing air leaks restore proper flow, reduce unnecessary pump vibration, and ensure your system maintains optimal pressure. Additionally, understanding the pressure regulation can help optimize system performance and prevent future issues.

Preventative Measures to Maintain Optimal Pressure

Implementing preventative maintenance is key to keeping your pump system operating at ideal pressure. Regular pump calibration ensures your system maintains accurate pressure levels and functions efficiently. Over time, sensors can drift from their calibrated settings, leading to incorrect pressure readings. By routinely inspecting and calibrating pressure sensors, you prevent inaccurate data that could cause pressure drops. Additionally, checking for wear and tear on pump components and ensuring proper pressure sensor placement helps maintain consistent pressure. Keeping filters clean and replacing worn parts prevents blockages that affect pressure. Scheduling these measures regularly reduces the risk of unexpected low pressure issues, extending your pump’s lifespan. Furthermore, understanding the role of contrast ratio in related systems can help in diagnosing image-related pressure readings and performance issues. Remember, proactive care is more effective and cost-efficient than reactive repairs.

Frequently Asked Questions

Can Low Pump Pressure Affect Overall System Efficiency?

Low pump pressure definitely impacts your system’s efficiency. When pressure drops, it can cause poor performance and increased energy use. Regular pump maintenance helps prevent these issues, ensuring your system runs smoothly. Conducting system diagnostics can identify underlying problems early. By maintaining your pump properly and monitoring system health, you optimize efficiency and avoid costly repairs or downtime caused by low pressure issues.

How Often Should Pump Pressure Be Checked for Optimal Performance?

You should check your pump pressure regularly to guarantee excellent performance. Daily pressure monitoring helps catch issues early, preventing system inefficiencies. Additionally, performing pump calibration every few months guarantees accuracy and consistent flow. Consistent checks keep your system running smoothly, reduce downtime, and extend your pump’s lifespan. Make it a habit to monitor pressure and calibrate as needed, ensuring your system operates efficiently and reliably over time.

Are There Specific Signs Indicating Imminent Pump Failure?

You should watch for signs like inconsistent pressure readings, strange noises, or frequent pressure drops, which indicate imminent pump failure. Regular pump maintenance and pressure monitoring help catch issues early. If you notice these symptoms, check your equipment promptly. Addressing these signs quickly prevents major damage. Staying vigilant with pressure monitoring and routine maintenance guarantees your pump operates smoothly, reducing the risk of unexpected breakdowns and costly repairs.

What Safety Precautions Should Be Taken During Pump Inspection?

Think of inspecting your pump like handling a ticking time bomb—you need to stay safe. Always wear personal protective equipment, including gloves and eye protection, to shield yourself from potential hazards. Follow a thorough inspection checklist to make certain no detail is missed. Turn off the pump and depressurize the system before inspection. These precautions keep you safe while you identify issues that might cause future failures.

How Do Environmental Factors Influence Pump Pressure Stability?

Environmental impact and temperature fluctuations can profoundly influence pump pressure stability. When temperatures rise or drop unexpectedly, it causes the fluid’s viscosity to change, affecting flow and pressure. Additionally, external factors like humidity, dirt, or corrosion can impact pump components, leading to pressure inconsistencies. To maintain stable pump pressure, you need to monitor environmental conditions regularly and implement protective measures, ensuring the pump operates efficiently regardless of environmental changes.

Conclusion

By regularly inspecting and maintaining your pump, you can catch issues early and keep it running smoothly. Address blockages, leaks, and worn parts promptly to prevent pressure drops. Remember, a stitch in time saves nine—staying proactive saves you from bigger problems down the line. Keep an eye on your system, and you’ll guarantee peak performance and avoid costly repairs. Consistent care is the key to reliable pump operation.