To avoid kickback injuries, you should understand the common causes, like blades catching or binding, and follow proper safety practices. Always use sharp, well-maintained equipment, verify safety guards are in place, and align blades correctly. Use correct cutting techniques, maintain a stable stance, and guide the saw smoothly. Wear appropriate PPE and keep your work area clean and organized. Stay alert and vigilant—learn more to keep yourself safer during cutting tasks.

Key Takeaways

- Use sharp, properly aligned blades and ensure guards are in place and functioning correctly.

- Maintain a firm, stable stance and guide the saw smoothly with both hands.

- Follow manufacturer instructions and avoid forcing the tool during cuts.

- Keep the work area clean and free of clutter to prevent distractions and tripping hazards.

- Wear appropriate PPE like safety goggles and dust masks to stay protected and focused.

Understand the Causes of Kickback

Understanding what causes kickback is essential to preventing injuries. Many safety misconceptions exist about how kickback happens, often leading to risky behaviors. The common hazards include improper handling of power tools, using dull blades, or applying excessive force. When you don’t keep a firm grip or avoid following manufacturer instructions, you increase the likelihood of sudden tool reactions. Recognizing these hazards helps you stay alert and prepared. Most kickbacks occur when the tool’s blade or chain catches or binds unexpectedly, causing it to jerk backward. Using proper safety techniques and understanding the causes of kickback can significantly reduce your risk. Additionally, ensuring that blades and chains are sharp and well-maintained is crucial for preventing tool binding. Staying informed about safety protocols can further help you avoid accidents and injuries. Being aware of power tool safety protocols further minimizes the likelihood of accidents. Proper tool maintenance plays a vital role in avoiding unexpected incidents. By understanding these causes, you can adjust your technique and stay safe. Avoiding common hazards and debunking safety misconceptions empowers you to work confidently and minimize the risk of injury.

Use Proper Tools and Equipment Safely

Using the right tools and equipment correctly is vital for preventing kickback injuries. Start by choosing power tools designed with good ergonomics, which help you maintain control and reduce fatigue. Always follow manufacturer instructions and use safety features like guards and anti-kickback mechanisms. Proper power tool ergonomics means keeping a comfortable grip and maintaining a stable stance to avoid slips. Additionally, practicing tool storage safety is essential; store tools securely and in designated areas to prevent accidents and damage. Inspect tools before use, ensuring blades are secure and functioning correctly. Avoid using damaged equipment, and never force tools beyond their intended capacity. Incorporating proper maintenance routines can also prevent unexpected malfunctions that lead to injuries, ensuring your tools operate safely and reliably. Regularly reviewing safety protocols and staying updated on safety standards can further reduce risks. By handling tools properly and prioritizing safety measures, you minimize the risk of kickback injuries and work more efficiently. Incorporating remote hackathons can also provide opportunities for skill development and safety training in a virtual environment, enhancing overall safety awareness. Remember, awareness of potential hazards is key to creating a safe work environment and preventing injuries.

Maintain Sharp and Well-Adjusted Blades

Regularly inspect your blades to catch dullness or damage early. Use proper sharpening techniques to keep them effective and safe. Always follow correct adjustment procedures to guarantee they function properly and reduce kickback risks. Incorporating routine maintenance can further help identify potential issues before they become hazards. Additionally, ensuring your blades are properly aligned and balanced can prevent uneven wear and improve overall safety during use. Proper blade installation is crucial for maintaining safety and performance. Being aware of relationship dynamics can also foster better communication and cooperation when working with others, which is essential for safety. Moreover, understanding safety protocols related to blade handling can significantly decrease the likelihood of injuries.

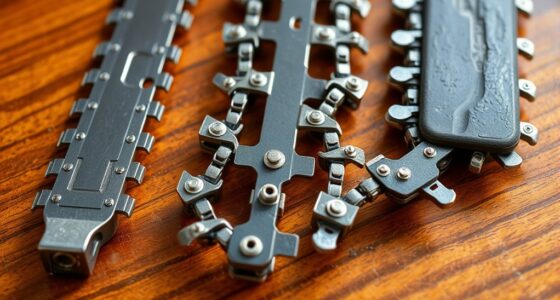

Regular Blade Inspections

To prevent kickback injuries, you need to keep your saw blades sharp and properly adjusted. Regular blade inspections help guarantee blade alignment is correct, reducing the risk of binding or uneven cuts. Check for dull blades that can cause increased friction and debris buildup. Proper dust management also plays a role by keeping the work area clear, preventing debris from interfering with saw operation. Use the table below to guide your inspections:

| Inspection Focus | What to Look For | Action Needed |

|---|---|---|

| Blade Alignment | Misalignment or wobbling | Adjust or replace blade |

| Dullness | Dull or chipped edges | Sharpen or replace blade |

| Dust Management | Excess debris buildup | Clean blades and surrounding area |

Regularly inspecting and maintaining blades keeps your saw functioning safely and efficiently. Maintaining proper safety procedures is also essential to prevent injuries during operation. Additionally, understanding cutting techniques can help reduce the likelihood of accidents. Incorporating correct blade selection ensures compatibility and optimal performance for different cutting tasks.

Proper Blade Sharpening Techniques

Keeping your saw blades sharp is key to safe and efficient cutting. Dull blades compromise blade durability, increasing the risk of kickback. To maintain peak performance, sharpen blades regularly based on your cutting frequency—more frequent use demands more frequent sharpening. Use the right tools, such as a sharpening stone or a specialized grinder, to keep the blade edges true and free of nicks. Always follow the manufacturer’s guidelines for sharpening angles to ensure consistency. Properly sharpened blades cut smoothly, reducing the force needed and minimizing the chance of the blade catching or binding. Remember, a well-maintained, sharp blade not only prolongs blade durability but also greatly boosts cutting safety, helping you avoid injuries caused by blade dullness or improper sharpness. Additionally, understanding proper Audi Tuning techniques can inspire you to optimize your equipment for safer, more efficient operation. Regular maintenance of your tools, including blade alignment, is also crucial to prevent uneven cuts and potential hazards. Proper blade tension ensures your saw operates smoothly and reduces the risk of accidents caused by blade wobbling. Furthermore, maintaining cooling systems to prevent overheating can extend blade life and improve safety during prolonged cutting tasks. Moreover, maintaining optimal blade cooling can prevent overheating, which can lead to blade warping or failure.

Correct Adjustment Procedures

Ensuring your saw blades are properly adjusted is essential for safe and effective cuts. Start by checking blade alignment; a misaligned blade can cause binding and kickback. Use a square or alignment tool to verify that the blade is square to the table and fence. Additionally, confirm that the safety guard is correctly positioned and moves freely, covering the blade when not cutting. Proper safety guard positioning prevents accidental contact and keeps debris away from your hands. Always tighten the blade and guard adjustments securely before cutting. Regularly inspect these adjustments, especially after transportation or maintenance. Correctly aligned blades and properly positioned safety guards reduce the risk of kickback, helping you work safely and efficiently.

Follow Correct Cutting Techniques

Following correct cutting techniques is essential for preventing kickback injuries. Always prioritize blade safety by ensuring the blade is sharp and properly guarded. A dull blade requires more force, increasing the risk of slipping and kickback. Maintain a stable cutting posture by standing with your feet shoulder-width apart and keeping your hands clear of the blade’s path. Use both hands to guide the saw smoothly through the material, avoiding sudden movements. Never force the saw or rush the cut; let the blade do the work. Keep your focus on the cutting line and avoid distractions. Proper technique minimizes strain on the tool and reduces the chance of mishaps. By adhering to these practices, you considerably lower your risk of injury caused by kickback.

Wear Appropriate Personal Protective Equipment

Wearing the right personal protective equipment (PPE) is essential for preventing injuries while operating power tools. Safety goggles shield your eyes from flying debris, wood chips, and dust that can cause serious injuries. Always wear them securely to maintain clear vision and protection. Dust masks are equally important, as they prevent you from inhaling fine dust particles that can irritate your respiratory system or lead to long-term health issues. Make sure your PPE fits properly and is in good condition before starting work. Proper gear not only protects you from kickback-related injuries but also keeps you focused and confident while handling power tools. Never skip PPE, because safety should always be your top priority during cutting and other power tool tasks.

Keep Work Areas Clean and Organized

A cluttered work area increases the risk of kickback and other accidents. To reduce hazards, keep your workspace organized with effective storage solutions that prevent tools and materials from cluttering your path. Proper storage not only reduces tripping hazards but also ensures tools are readily accessible, minimizing the need to search and potentially mishandle equipment. Clear signage helps improve signage clarity, guiding you safely around the work zone and alerting you to potential dangers. Regularly clean your work area to remove sawdust, debris, and leftover materials that can cause slips or interfere with equipment operation. An organized, tidy space allows you to focus better, react quickly to hazards, and maintain safety standards, considerably lowering the chances of kickback injuries.

Receive Proper Training and Stay Alert

Proper training equips you with the knowledge to operate tools safely and effectively, reducing the likelihood of mistakes that can lead to kickback injuries. By following established safety protocols, you guarantee you understand how to handle equipment properly and recognize potential hazards. Staying alert while working helps you respond quickly to changing conditions and avoid risky situations. Regular hazard awareness keeps you prepared for unexpected obstacles or tool malfunctions that could cause kickback. Don’t skip safety training or become complacent—these are vital for your safety. When you stay focused and adhere to safety protocols, you minimize your risk of injury and maintain a safe work environment. Proper training and alertness are your best defenses against kickback injuries.

Frequently Asked Questions

What Are the Most Common Injuries Caused by Kickback?

Kickback can lead to serious injuries, with saw blade injuries being the most common, often resulting in cuts or even amputations. You might also suffer hand lacerations from sudden blade contact or debris hitting your hands. These injuries happen when safety protocols aren’t followed, so always stay alert, use proper guards, and keep your hands clear of the blade’s path. Staying cautious helps prevent these potentially severe accidents.

How Often Should I Inspect My Tools for Safety?

Think of your tools as trusted partners in your work—regularly checking their health keeps them dependable. You should inspect your tools for safety at least once a week, especially before big jobs. Proper tool maintenance and safety inspections prevent accidents and ensure smooth operation. Don’t wait for something to go wrong; proactive care guarantees you safety, keeps productivity high, and extends the life of your equipment.

Can Kickback Occur With Power Tools Other Than Saws?

Kickback can happen with various power tools, not just saws. Power tool hazards include unexpected movements or injuries caused by tools like routers, drills, or planers. Safety training teaches you to recognize these risks and handle tools properly. Always wear protective gear, keep your workspace clear, and follow manufacturer instructions to prevent kickback. Being alert and prepared helps you avoid injuries during your projects, no matter which power tool you’re using.

What Are the Legal Safety Requirements for Woodworking Safety?

Safety standards stipulate strict safety regulations and inspection protocols to protect workers. You must understand and follow all safety regulations, ensuring your workspace is compliant and hazards are minimized. Regular inspection protocols help identify potential dangers early, preventing accidents. By diligently adhering to these rules and conducting thorough inspections, you create a safer woodworking environment, reducing risks and ensuring legal compliance for you and your team.

How Do I Select the Best Protective Gear for Kickback Prevention?

When selecting the best protective gear for kickback prevention, you should choose gear that keeps you safe and comfortable. Wear protective gloves to maintain grip and protect your hands, and always use safety goggles to shield your eyes from flying debris. Make sure your gear fits well and is made from high-quality materials. Proper protective equipment helps you work confidently and reduces the risk of injury during woodworking tasks.

Conclusion

While it’s tempting to believe that avoiding kickback is just about following rules, sometimes the biggest risk is thinking you’re invincible. Ironically, the more confident you feel, the more likely you are to overlook safety. Staying alert, using proper tools, and respecting your equipment might seem tedious, but they’re your best defenses. So, next time you’re about to cut corners, remember: a little caution today could save you from a costly injury tomorrow.