To prevent cavitation in hydraulic systems, guarantee you maintain proper fluid flow and pressure levels. Use appropriately sized pipes, smooth bends, and avoid sharp turns to reduce turbulence and pressure drops. Regularly inspect and maintain pumps, valves, and filters to prevent wear and obstructions. Monitoring system parameters helps you detect early signs of cavitation and make adjustments promptly. Continuing with advanced strategies can help you proactively protect your hydraulic system from cavitation damage.

Key Takeaways

- Maintain optimal fluid pressure and flow rates to stay above vapor pressure thresholds.

- Design piping with smooth bends and appropriate diameters to minimize turbulence and pressure drops.

- Regularly inspect and service components to prevent wear, blockages, and air leaks that promote cavitation.

- Monitor system pressure and flow continuously using sensors to detect early signs of low-pressure zones.

- Use pressure regulation devices and proper system layout to ensure consistent pressure and reduce vapor bubble formation.

Understanding the Causes of Cavitation in Hydraulic Systems

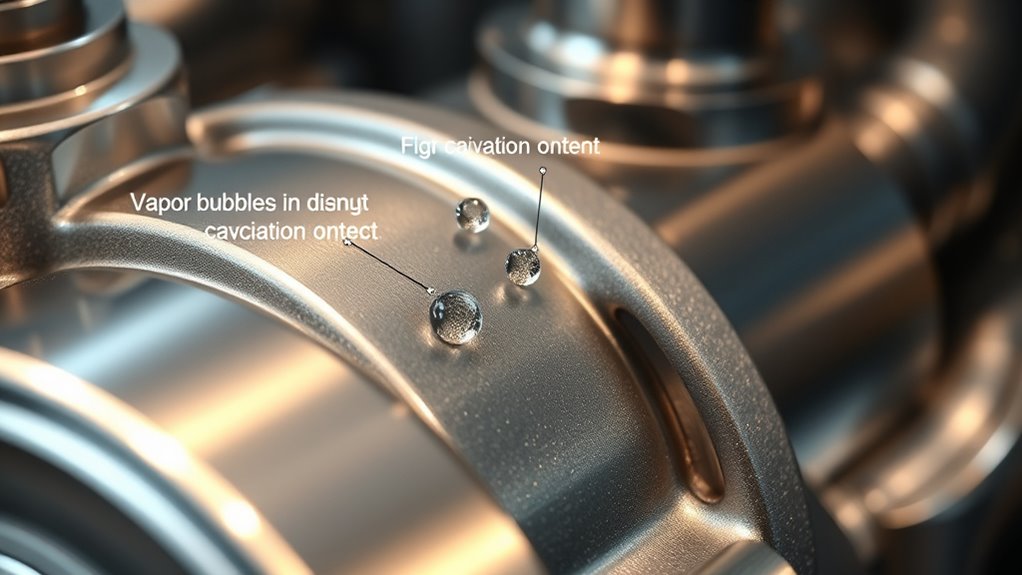

Cavitation occurs when the pressure in a hydraulic system drops below the vapor pressure of the fluid, causing bubbles to form. This usually happens when fluid velocity increases suddenly, such as at constrictions or bends, creating low-pressure zones. Another cause is inadequate fluid supply or improper system design, which can lead to pressure drops. Air entrainment also contributes, as air bubbles behave similarly to vapor bubbles during pressure changes. Additionally, using the wrong fluid or operating at excessively high speeds can heighten cavitation risk. When fluid flows rapidly or pressure drops unexpectedly, bubbles form and collapse violently, damaging components. Recognizing cavitation causes and their impact on system components is essential for maintaining hydraulic system integrity and longevity. Understanding the fluid dynamics involved can help predict and prevent cavitation issues before they cause significant damage. Moreover, pressure fluctuations resulting from system malfunctions can exacerbate cavitation, emphasizing the importance of proper monitoring and maintenance. Incorporating preventive measures, such as proper system design and regular inspections, can significantly reduce the likelihood of cavitation occurring. Properly controlling fluid flow and ensuring consistent pressure levels are crucial for effective cavitation prevention.

Recognizing the Signs and Effects of Cavitation

Since cavitation involves the formation and collapse of bubbles within your hydraulic system, you may notice specific signs indicating its presence. These signs help you identify cavitation early, preventing costly damage. Proper maintenance and monitoring can significantly reduce the risk of cavitation and its adverse effects. Regular inspection of fluid flow and pressure levels is essential to detect early warning signs associated with industry transformations, such as AI automation, which can improve diagnostic accuracy. These signs help you identify cavitation early, preventing costly damage. Recognizing fluid dynamics issues can further aid in early detection and mitigation strategies.

Designing Hydraulic Systems to Minimize Cavitation Risks

Effective hydraulic system design plays a pivotal role in minimizing cavitation risks by controlling fluid flow and pressure conditions. You should guarantee that fluid velocities stay below critical levels to prevent sudden drops in pressure that cause vapor bubbles. Incorporate proper pipe diameters and smooth bends to reduce turbulence, which can increase pressure fluctuations. Maintaining consistent pressure throughout the system minimizes zones of low pressure where cavitation could develop. Use strategically placed pressure relief valves and ensure adequate reservoir capacity to stabilize pressure fluctuations. Avoid sharp corners and abrupt changes in flow direction, which can cause localized pressure drops. Additionally, paying attention to noise levels of modern heat pumps can help ensure that the system operates quietly, promoting a more comfortable environment. Recognizing the importance of flow dynamics helps in designing systems that balance pressure and velocity effectively, reducing cavitation potential. Proper system maintenance practices are essential to prevent debris buildup and corrosion that can contribute to cavitation issues. Implementing pressure monitoring devices allows for real-time adjustments and early detection of potential cavitation zones, further safeguarding system integrity.

Selecting Appropriate Components to Prevent Vapor Bubble Formation

Choosing the right components is essential for preventing vapor bubble formation in hydraulic systems. Your goal is to select parts that maintain proper pressure and flow, reducing cavitation risk. Consider these factors:

- Use pumps designed for low NPSH (Net Positive Suction Head) requirements to prevent suction vaporization.

- Opt for valves with minimal pressure drops to avoid localized pressure drops that cause vapor bubbles.

- Select hoses and fittings with smooth interiors to reduce turbulence and flow restrictions.

- Choose pressure relief valves that maintain system pressure above vaporization thresholds during operation.

- Ensure that the system’s color accuracy is calibrated properly to monitor pressure fluctuations effectively.

Implementing Effective Pump and Valve Maintenance Practices

Regularly inspecting and maintaining pumps and valves is essential for preventing cavitation in hydraulic systems. You should check for signs of wear, corrosion, and leaks that can compromise component integrity. Keep your pump clear of debris and ensure it operates within the recommended parameters. Lubricate moving parts according to manufacturer instructions to reduce friction and prevent damage. Valves require regular calibration to ensure proper flow control, preventing sudden pressure drops that cause cavitation. Replace worn or damaged components promptly to avoid pressure fluctuations. Maintaining correct fluid levels and ensuring filters are clean also help sustain ideal pressure and flow. Additionally, using high-quality, properly stored herbal teas can help reduce stress and support overall system health, mirroring the importance of quality maintenance. Regularly monitoring pressure fluctuations can help detect early signs of cavitation before serious damage occurs. Employing proper maintenance practices minimizes the likelihood of low-pressure zones and vapor bubble formation, ultimately extending equipment lifespan and ensuring system reliability. Moreover, understanding the role of fluid dynamics in hydraulic systems can further optimize performance and prevent cavitation issues.

Monitoring and Controlling Operating Conditions to Avoid Low-Pressure Zones

You need to keep an eye on pressure levels to prevent low-pressure zones that cause cavitation. Using reliable pressure monitoring techniques helps you identify problem areas early. By adjusting system parameters accordingly, you can maintain ideal conditions and protect your equipment.

Pressure Monitoring Techniques

Effective pressure monitoring is essential for preventing cavitation in hydraulic systems because it helps identify and maintain ideal operating conditions. By keeping track of pressure levels, you can detect early signs of low-pressure zones that may lead to cavitation. Use reliable sensors placed at critical points to gather accurate data. Consider these key techniques:

- Install pressure transducers at strategic locations to continuously monitor pressure fluctuations.

- Use digital readouts for real-time pressure tracking, enabling quick responses.

- Implement data logging systems to analyze pressure trends over time.

- Set alarms and thresholds to alert you when pressures approach cavitation risk levels.

These techniques allow you to maintain system stability, prevent low-pressure zones, and extend equipment lifespan.

Adjusting System Parameters

How can adjusting system parameters help prevent cavitation in hydraulic systems? By fine-tuning factors like flow rate, pressure, and temperature, you can maintain ideal operating conditions that minimize low-pressure zones. For example, reducing flow rates in critical sections prevents pressure drops that cause vapor bubbles. Increasing system pressure with properly set relief valves keeps pressure above vapor pressure thresholds. Adjusting pump speeds ensures flow remains steady, avoiding sudden pressure fluctuations. Monitoring temperature helps prevent overheating, which can lower fluid viscosity and promote cavitation. Regularly inspecting and calibrating system components allows you to respond quickly to changes that could induce cavitation. Overall, controlling these parameters keeps pressure levels stable, reducing the risk of vapor bubble formation and protecting your hydraulic system from cavitation damage.

Troubleshooting Common Cavitation Problems and Solutions

Cavitation issues can cause significant damage to hydraulic systems if not addressed promptly. When you notice symptoms like noise, vibration, or reduced efficiency, troubleshooting becomes essential. First, check for low fluid levels, as insufficient fluid can cause pressure drops leading to cavitation. Second, inspect the inlet line for obstructions or air leaks that disrupt proper fluid flow. Third, verify that system pressure settings match manufacturer specifications; too low pressure can cause vapor bubbles. Finally, examine the pump for wear or damage, which can create turbulent flow and cavitation. Addressing these issues promptly can prevent further damage, extend equipment lifespan, and maintain system performance. Regular maintenance and vigilant monitoring are your best tools for avoiding cavitation problems.

Frequently Asked Questions

How Does Fluid Temperature Influence Cavitation Risk?

Fluid temperature plays a vital role in cavitation risk because warmer fluids tend to have lower viscosity and vapor pressure. When the temperature rises, the fluid’s vapor pressure increases, making it easier for vapor bubbles to form and collapse, which can cause cavitation. Conversely, cooler fluids have higher viscosity and lower vapor pressure, reducing cavitation likelihood. You should monitor and control fluid temperature to minimize cavitation damage.

Can Additive Chemicals Reduce Cavitation in Hydraulic Fluids?

Did you know that adding certain chemicals can boost hydraulic fluid lifespan by up to 50%? When you ask if additives reduce cavitation, the answer is yes—they can improve lubrication and cushion vapor bubble formation. You should choose additives carefully, ensuring they’re compatible with your system. These chemicals can help minimize cavitation risks, but proper maintenance and fluid management remain essential for ideal system performance.

What Role Does System Layout Play in Cavitation Prevention?

You understand that system layout substantially impacts cavitation prevention. By designing your hydraulic system with smooth pipe bends, appropriate pipe diameters, and proper pump placement, you minimize pressure drops that cause cavitation. Ensuring the fluid flow remains steady and avoiding sharp turns or restrictions helps maintain consistent pressure levels. With a thoughtful layout, you reduce the risk of vapor bubble formation, ultimately protecting your system’s efficiency and longevity.

Are There Specific Hydraulic Fluids More Resistant to Cavitation?

You might wonder if certain hydraulic fluids resist cavitation better. Typically, fluids with higher viscosity and proper lubrication properties help reduce cavitation risk. Synthetic fluids often outperform mineral oils because they maintain stable pressure and flow. Using fluids with appropriate additive packages can also minimize vapor bubble formation. Always choose a fluid suited for your system’s operating conditions to enhance cavitation resistance and guarantee reliable hydraulic performance.

How Does Altitude Affect Cavitation Tendencies in Hydraulic Systems?

Altitude impacts cavitation tendencies because higher elevations mean lower atmospheric pressure, which can cause your hydraulic fluid to vaporize more easily. As pressure drops, bubbles form within the system, increasing cavitation risk. To counter this, you should consider adjusting system pressure settings, using fluids with higher vapor pressure thresholds, and ensuring proper venting. These steps help maintain system integrity and prevent cavitation issues caused by altitude changes.

Conclusion

To prevent cavitation, you need to understand its causes and recognize its signs early. By designing your system carefully, choosing the right components, and maintaining equipment properly, you can keep vapor bubbles at bay. Think of your hydraulic system like a river—you want smooth flow without low-pressure whirlpools. Regular monitoring and quick troubleshooting help you stay ahead, ensuring your system runs efficiently and avoids costly damage caused by cavitation.